|

Reactivating

a Springfield

1903-A3 Drill Rifle

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Table

of Contents: Click

on a topic to move to that subject.

Introduction

When

I was in high school I attended a military class run by the California

Cadet Corps which was under the California National Guard.

In fact, I was the commander of the unit my junior and

senior years. We

used deactivated Springfield

1903-A3 rifles for drill; the barrel was plugged, the bolt

face was welded, and the striker was ground down, but

everything else on the rifle was functional.

Most of us cadets wanted to own one of these rifles, so

ever since my high school days I’ve wanted to have a

functioning

Springfield

1903-A3. When

I was in high school I attended a military class run by the California

Cadet Corps which was under the California National Guard.

In fact, I was the commander of the unit my junior and

senior years. We

used deactivated Springfield

1903-A3 rifles for drill; the barrel was plugged, the bolt

face was welded, and the striker was ground down, but

everything else on the rifle was functional.

Most of us cadets wanted to own one of these rifles, so

ever since my high school days I’ve wanted to have a

functioning

Springfield

1903-A3.

A reader of

the Kitchen Table Gunsmith, Ray, recently contacted me asking

for permission to use my disclaimer on his web site.

I gave him permission, but wanted to know what he was

working on since I am always interested in a new gunsmithing

project. His

excellent article, with many very helpful photos, explained

how to convert a deactivated Springfield

1903-A3 drill rifle into a shooter titled 03-A3

Drill Rifle Facts and Recovery Process.

He had apparently purchased a batch lot of these

deactivated drill rifles from the Civilian

Marksmanship Program (CMP) and was selling parts and

complete rifles. I

purchased a complete rifle from him for the mere price of $220

including shipping to my FFL dealer.

A few minutes of paperwork plus $15 transfer fee put

this piece of American military history in my hands.

Prior to

adoption of the

Springfield

in 1903 the official rifle of the U.S. Military was the .30-40

Krag-Jorgensen. This

rifle had many shortcomings that were exposed during the 1898

Spanish-American war, especially when compared to the 1898

Mauser. Development

of a new rifle began in 1900 with the final design being

adopted in 1903 based on the Mauser action.

Eventually the

United States

had to pay royalties to Mauser Werke in

Germany

since the action was very similar, but when WWI hostilities

broke out the

United States

stopped paying royalties.

Production of the 1903-A3 variant began in 1941 and

ended in 1944, however the rifle continued to be used in both

Korea

and Vietnam.

I’ve

always been fascinated with

U.S.

military rifles. I

currently have an AR15, M1A, M1 Carbine, and M1 Garand in my

collection; all are functioning shooters.

A

Springfield

1903-A3 was a rifle missing from my 20th century

U.S.

military rifle collection.

After I picked up my rifle from my FFL dealer I did a

little research on the Internet and found M1903.com;

a web site dedicated to 20th century

U.S.

military firearms. It

turns out my rifle was built by Remington in August, 1943

which coincides with the date stamp of 7/43 on the ruined

barrel. An

interesting side note; my newer model M1 Garand has an older

Springfield Armory receiver built in 1942, but my older model

’03-A3 has a newer Remington receiver built in 1943!

Initial

Assessment

I completely disassembled the rifle for

inspection and to determine what work I needed to perform, and

what parts I needed to replace.

This is what I found:

- No

front sight blade –The rifles we had in high school had

the front sight blade installed, but I remember numerous

cadets, including myself, getting cut by them during drill

exercises so that is probably why this rifle didn’t have

one.

- It

looked like the magazine cutoff had been welded, but

someone had worked on it to make it function again.

- Rear

sight base peened and bent – probably from cadets

dropping the rifle multiple times, but I was still able to

adjust the sight for windage and elevation.

- Firing

pin hole welded on the bolt face

- Striker

(firing pin) was cut off so just the collar was left.

- Chamber

was torched and a steel rod welded in place

- Barrel

was tack welded to the receiver

- Missing

ejector and ejector pin

- Safety

would not rotate

- Upper

band was loose

- Upper

band screw was stripped

Broken

Safety Plunger

To my

surprise I couldn’t rotate the safety, which made

disassembling the bolt a bit challenging.

I discovered the shaft was broken off of the safety

plunger. This

shaft guides the plunger into the hole, but now that it was

broken, the plunger was hitting the side of the plunger hole

effectively blocking it so it couldn’t move down.

I used a small screwdriver to align the plunger with

the hole and pushed down so I could rotate and remove the

safety. I’m

guessing since the plunger is longer than the space between

the shaft and the lever it was installed prior to installing

the shaft. I’ll

have to purchase a new safety assembly.

Removing

the Handguard Ring

The handguard ring would not come off because of

the tack weld on the bottom of the barrel.

I took a safe-edge #0 narrow pillar file #191-400-760

I purchased from Brownells and filed down the top of the weld

until it was even with the rest of the receiver so I could

slip the ring off of the barrel.

This turned out to be a stainless steel weld and would

not take parkerizing, but this was not a problem since the

weld was on the underside of the receiver and would be covered

by the stock.

Removing

the Welded Magazine Cutoff

Removing the welded magazine cutoff was much easier

than anticipated. Since

it was functioning all I had to do was remove the magazine

cutoff screw and spindle and remove the magazine cutoff from

the receiver. Although

the magazine cutoff functioned correctly, because this part

was so damaged from the welding I purchased a new one.

Milling

Magazine Cutoff Detents

Probably the ugliest part of this rifle was the

cratered receiver where the magazine cutoff was welded.

I could have had this TIG welded and then reshaped it,

but I decided to leave it and just re-parkerize it.

Leaving it as is I can brag about how I recovered a

drill rifle and show where it was originally welded.

However, I wanted the magazine cutoff to function

correctly so I cleaned up the detents.

I took a

3/32” ball end milling bit and my high-speed rotary tool set

to the lowest speed and opened up the welded center detent.

I took a cone-shaped grinding bit and ground in the

beveled approaches on both sides of the new detent.

I then took a cone-shaped rubber polishing bit and

again used my high-speed rotary tool to polish out the

grinding marks on the beveled approaches.

I reinstalled the old magazine cutoff and tested it

with the bolt and everything worked as it should.

The center detent was in the proper position so the

bolt could be removed and installed easily.

I also cleaned up the ON and OFF detents with the

3/32” ball end bit because they had some metal splash from

the welding. Now

the magazine cutoff plunger sets securely into each of the

three detents.

Ok, so what

does the magazine cutoff do?

In the down or OFF position it will not allow the bolt

to come back far enough to feed rounds from the internal

magazine essentially making it a single-shot rifle.

In the center position it allows the bolt to be removed

and installed. In

the up or ON position it allows the bolt to come back far

enough so the rifle will feed rounds from the internal

magazine. Also

when in the ON position, after the last empty case is

extracted and ejected the follower prevents the bolt from

closing thereby indicating that the magazine is empty.

Cleaning

up Rear Sight Base

I

completely disassembled the rear sight and noticed that the

sight base was heavily staked onto the receiver.

I found on the Internet that this seems to be common

with rifles manufactured by Remington so I decided just to

leave it alone and treat it as part of the receiver.

I took a steel punch and pounded the sides of the rear

sight base until they were straight.

I took a file and cleaned up the burrs on the top of

each side, then used a rubber polishing tip and my high speed

rotary tool to polish out the file marks.

When I re-parkerize the receiver this will look great!

Removing

the Barrel

The most difficult part of the recovery process was

removing the welded barrel.

Ray used a lathe to not only remove the barrel weld,

but to remove enough of the barrel shoulder to reduce the

interference fit of the barrel to receiver face so he could

remove the barrel with a pipe wrench.

I don’t have a lathe so to remove the weld I used the

same safe-edge #0 narrow pillar file I used previously.

I started

at the end of the weld and rested the safe edge of the file

against the receiver face.

I began filing the weld being careful not to cut into

the receiver face. After

I filed off some of the weld to expose the barrel I rotated

the rifle so I could file off more of the weld.

I always made sure the safe edge of the file was

resting against some exposed receiver face to keep the file

square and flat.

Because the

weld was so high I started filing on the other end of the weld

being careful as before. You

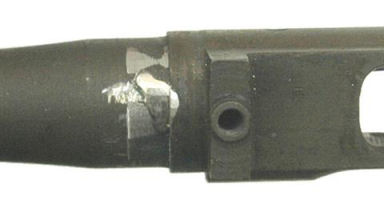

can see in the above photo that the weld started to form a

point at the top where both filed sides met.

I continued

to file both sides of the weld until I had a bare-metal cut in

place of the weld indicating that I had removed the weld metal

and had started to cut into the barrel.

I filed a little deeper to make sure I had removed the

entire weld.

Because I

didn’t go completely around the barrel shoulder I still

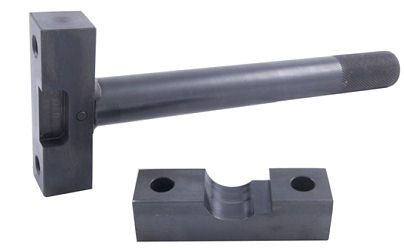

needed to use an action wrench and barrel vise to remove the

barrel. I already

had the action wrench from Brownells so all I needed was the

Springfield

1903 Head #080-801-003.

A properly fitting head is important because this

prevents the receiver from warping or otherwise becoming

damaged when removing the barrel.

I also

already had the barrel vise, but I didn’t have a bushing

that fit the barrel, so I had to make one.

I marked the barrel just in front of the chamber swell,

and made another mark 1 1/8” farther down the barrel.

The barrel diameter measured at the two marks was

0.980” and 0.942” respectively meaning the barrel had a

0.968o taper. If

you are interested in how I calculated the amount of taper,

the math is at the end of this article.

I used BobCAD-CAM v20

to create the

CAM

code, then used my MAXNC

10 CL hobby CNC mill to mill the bushing from 1 1/8”

aluminum stock.

No matter

how hard I tried I couldn’t remove the front sight base from

the barrel, so I cut off the barrel about one-inch behind the

front sight base. This

is a throw-away barrel anyway and I ordered a replacement

front sight base.

I attached

the receiver wrench to the front of the receiver using the

Springfield

1903 head. I

coated the inside and outside of the barrel bushing with rosin

I purchased from Brownells #083-016-100,

positioned it on the barrel, then installed and tightened the

barrel vise onto the bushing.

I positioned the barrel vice in a well-supported bench

vise and used a 2-foot length of pipe on the action wrench to

gain some additional leverage.

Thanks to this additional leverage the barrel easily

came loose, even after almost 70 years.

As my father taught me; it helps to have the right

tools!

Replacement

Parts

I purchased the following parts from Gun

Parts Corporation (Numrich).

All the replacement parts came stamped with an “R”

indicating they were all manufactured by Remington; a perfect

match for my rifle.

- 1087210

new barrel

- 514340B

safety lock assembly

- 514510 striker

- 515370 magazine

cutoff

- 524910 front

sight base

- 524650 front

sight key

- 524900 front

sight blade

- 514520 bolt body

- 515760 ejector

- 515750 ejector

pin

Re-Parkerizing

I not only wanted my rifle to function like new, I

also wanted it to look like new so I decided to re-parkerize

the visible parts. Parkerizing

is a very simple, inexpensive process that applies a more

durable finish than bluing.

This is why manufacturers starting parkerizing military

guns to keep up with the demands of two world wars.

Parkerizing also covers up nicks, scratches, and other

imperfections, and this rifle has almost 70 years of

imperfections and cadet mishandling!

I have parkerized a number of guns and each one came

out beautifully.

I purchased

a jumbo combination (black & grey) parkerizing kit from Home

Parkerizingkits.com. I

used the grey to match the original military parkerizing on

early ’03-A3’s. Later

rifles came with a grey/green parkerizing.

I took all

the parts I wanted to re-parkerize and first removed any

unsightly burrs. The

new bolt body I received was blued and packed in cosmolene so

I first had to remove all the grease.

I bead-blasted the parts down to bare metal which gave

them a nice, even matte finish.

I thoroughly cleaned and degreased all the parts, and

prepared the grey parkerizing solution according to the

instructions. I

used nylon cable ties to suspend the parts and provide a means

to remove the part from the hot parkerizing solution.

I heated the solution in a large stainless-steel

cooking pot to 190oF and immersed the parts.

After the

parts stopped bubbling I removed them from the pot, thoroughly

rinsed them with hot water, then coated them with the provided

light oil. The

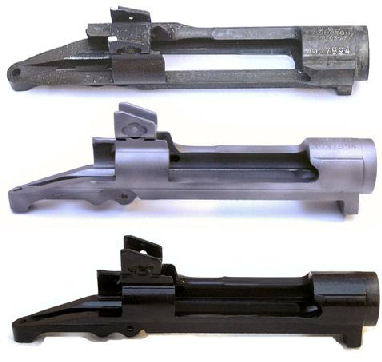

above photos show (from top to bottom) the original part, bead

blasted, and parkerized. As you can see from the

photos they came out very nice.

Some areas

on the receiver and the bolt sleeve wouldn’t take the

parkerizing. I

bead-blasted them again and then dipped them in an acid bath

made of 1 part muriatic acid and 4 parts tap water for about

30-seconds, then

thoroughly rinsed them in tap water.

This time the parkerizing came out evenly.

Polishing

and Mating the Bolt Locking Lugs

After I parkerized the parts I polished the bolt locking

lugs on the new bolt. This

ensured that the bolt locking lugs mated evenly with equal

pressure which can provide some increase in accuracy.

This process can also change headspace which is why I

performed it before I installed the new barrel.

I installed

a spring onto the steel rod that was welded into the chamber

of the old barrel. I

screwed the old barrel onto the receiver so the spring applied

tension on the closed bolt.

I removed the bolt, applied some 800-grit lapping

compound onto the recoil lugs, then closed the bolt.

I opened and closed the bolt about 45-degrees to lap

the recoil lugs. The

spring applied rearward pressure on the bolt to facilitate the

lapping process.

After 10-20

open/close cycles I removed the bolt, cleaned the locking lugs

with brake parts cleaner and examined the progress.

I applied more lapping compound and continued the

open/close lapping process until both lugs were evenly lapped.

I removed the old barrel and cleaned both the receiver

and bolt with brake parts cleaner.

Installing

the New Barrel

The barrel I ordered from Numrich had a few

problems. First of

all there was no alignment mark on the side of the barrel as

found on military barrels.

So the only way I was able to index the barrel properly

was to install the front sight base and “eyeball” it.

I

discovered the slot in the barrel for the sight base key was

too wide. The

front sight base would not fit tightly onto the barrel because

the wide slot allowed the sight base to rotate.

I peened the edges of the slot until the key fit

tightly, then I silver-soldered the key in place.

Now the front sight base fits tightly onto the barrel

and does not rotate.

I screwed

the new barrel onto the receiver until it was hand-tight and

discovered that the barrel was rotated about 75o

which would make it way too tight.

The proper method for reducing the interference fit is

to turn down the barrel shoulder on a lathe, however as

mentioned before I do not have a lathe.

Another method for reducing the interference fit is to

use 400-grit lapping compound and lap the barrel shoulder to

the receiver. This

technique comes from Accurizing

the Factory Rifle by M. L. McPherson.

This method removes metal from both the receiver face

and barrel shoulder, but it also squares these two surfaces.

Because I am removing metal from the receiver face I

may not be able to put another barrel on this receiver.

Not a problem because I don’t plan to ever put

another barrel on this rifle.

I screwed

the new barrel onto the receiver until the barrel shoulder was

about 1/8” away from the receiver.

I took a toothpick and put some 400-grit lapping

compound into that space, then screwed the receiver down hand

tight. I needed to

be careful that I didn’t get any lapping compound onto the

barrel threads. I

set the barrel straight up in a vise and alternately loosened

and tightened the receiver.

After about 50 or 60 cycles of loosening and tightening

I cleaned off the lapping compound with brake parts cleaner

and checked my progress. A

grey ring was starting to form around the barrel shoulder and

receiver face.

I continued

this process until the barrel was about 16-degress off to the

right. This will

provide the correct amount of interference fit (tightness) for

the barrel and receiver. Also

there was a solid grey ring around the barrel shoulder and

receiver face indicating that the barrel was lapped and square

to the receiver.

I coated

the barrel bushing with rosin as before and slid it onto the

barrel. I

installed the barrel vise onto the bushing, and installed the

action wrench onto the receiver.

I put the barrel vise into the well-supported bench

vise and tightened the receiver until the front sight base was

vertical and centered.

Reaming

the Chamber

The new barrel came with a chamber that was cut

0.005” short so I had to finish reaming the chamber to the

proper headspace. First

I measured the headspace of the new barrel.

A very important procedure when replacing a barrel is

to check the headspace. I

used the new bolt body so just the bolt face came in contact

with the gauge. When

testing headspace there should be no extractor or ejector

tension on the gauge.

I inserted

a .30-06 Go headspace gauge into the chamber and gently tried

to close the bolt body using just light finger pressure.

I never try to force a bolt closed on a gauge; light

finger pressure is all that is needed.

I used the Go gauge because this was a new barrel with

a short chamber. The

above photo shows that the bolt would not close all the way.

This is the point where I just started to feel some

friction. Because

the bolt would not close on the Go gauge indicated that the

chamber was too short.

I rented a

.30-06 chamber reamer from Elk

Ridge Reamer Rentals.

When it arrived I pushed the pull-through rod through

the chamber and out the bore until the reamer was visible in

the receiver. I

liberally lubricated it with cutting oil then pulled the rod

until I felt the reamer contact the chamber.

I gave it about 10 turns clockwise as viewed from the

muzzle; never

counterclockwise as this could break the cutting teeth.

I could feel the reamer cutting into the new barrel as

it cut a longer chamber and new throat.

I pushed

the reamer back into the action.

As shown in the above photo the flutes had steel dust

from the reaming process.

I removed the reamer and rod by pulling them back

through the action. I

thoroughly flushed the reamer and chamber with brake parts

cleaner to remove all chips and cutting oil, then ran a clean

dry patch through the bore from the chamber to the muzzle.

I used the Go headspace gauge to measure headspace as

described before. The

bolt still would not close on the Go gauge indicating I had to

do more cutting.

I repeated

the cut 10 turns, clean and measure process until the bolt

would completely close with the Go gauge in place.

The chamber and throat were now cut to the proper

length. I also

measured headspace with a .30-06 Field gauge just to make sure

the chamber was within specification and the bolt would not

close.

Reassembly

After I finished reaming the chamber I completely

reassembled the rifle with the replacement parts.

Everything went together as it should, and the re-parkerized

parts made the rifle look almost factory new.

Also the front sight base key didn’t have a notch so

I drilled a notch so the pin would fit.

I made sure all moving parts were either oiled or

greased before assembly.

Since all

the parts were now re-parkerized, which is a rough finish, the

bolt didn’t slide as easily and smoothly as it did before.

I purchased a tube of IOSSO bore cleaner from Brownells

#073-000-002

which has a very fine grit.

I put some on a Q-tip and spread it along the receiver

where the bolt travels. I

opened and closed the bolt about 20 times while placing

downward pressure on the bolt.

I cleaned off the excess cleaner from the bolt lugs and

receiver. Both the

bolt and receiver had streaks where the Parkerizing was

polished off. Working

the bolt while watching TV also helps to polish those newly-parkerized

surfaces!

Tightening

Upper Band

The upper band was very loose and it looked like

someone tried to tighten it by over-tightening the upper band

screw causing it to strip.

The upper band hole in the stock was too large causing

a large amount of slop and play in the upper band.

This may have been done on purpose to prevent cadets

from installing a bayonet.

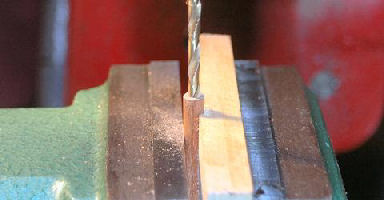

First I

drilled out the hole in the stock to 1/4”.

Then I took a piece of 1/4” hardwood dowel, cut it to

1 1/4”, and drilled a hole through the center using a #29

drill bit.

I glued the

hollow dowel into the stock, then cut and filed the ends flush

with the stock. I

reamed the hole with a #26 bit until the upper band screw

would fit and meet the threaded hole when installed with the

upper band. Now

the upper band has no slop or movement.

Polishing

Extractor Face

I discovered that the extractor wouldn’t slip

over the rim of a single-fed cartridge; however it worked

perfectly when feeding rounds from the magazine.

I put a rubber polishing tip on my high-speed rotary

tool and polished the face of the extractor.

Originally it had a sharp edge transitioning to the

bevel. I polished

that edge and the bevel, then cold-blued the entire extractor.

Now the extractor slips easily over a single-fed

cartridge.

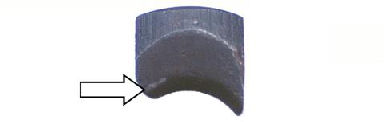

In the

above photo you can see a light area on the lower left of the

extractor face (indicated by the arrow) where the extractor

rubbed against the case head when single feeding.

This is the beginning of the transition line from the

extractor face to the bevel and was the area I polished.

This edge has to be smooth enough so when the extractor

meets the cartridge head it cams over the rim of the

cartridge.

Barrel

Break In

I performed this barrel break-in procedure with my

new M1 Garand barrel and it worked very well. It

is a combination of hand and fire lapping to polish the

chamber throat and lap the bore.

The purpose of this procedure is to polish out any

burrs left in the barrel throat from the reamer, and to polish

and gradually taper the barrel for increased accuracy and ease

of cleaning. Burrs

in the chamber throat can literally tear copper from a bullet

and cause excessive copper fouling in the bore.

Traditional

fire-lapping drives bullets impregnated with lapping compound

through the bore at very low velocities.

Cases used for fire-lapping have to be thrown away

because the brass case neck gets contaminated with the lapping

media. Although

this method does wonders for the bore, it also lengthens the

barrel throat which can reduce barrel life.

My method polishes the throat without increasing its

length, laps the bore and I don’t have to throw away the

cases!

First I

loaded 15 rounds of .30-06 with 5.0 grains of Red Dot behind a

150 grain FMJ boat tail .308 bullet and a large rifle magnum

primer. I use

magnum primers because there is so little powder in the case,

and anything less than 5.0 grains of powder will cause the

bullet to get stuck in the bore.

I put a

bore guide in the action to prevent the lap from depositing

compound in the chamber. I

wrapped a .45 cleaning patch around a 25-caliber bore brush,

and then impregnated the patch with USP

Bore Paste™ that I purchased from Midway

USA #

257358. I ran

the tight-fitting patch back and forth through the entire

length of the bore 20 times being careful not to allow the lap

to come all the way out of the muzzle, or all the way into the

chamber. This

performed the hand lapping part of the process and left a

small amount of compound in the bore.

I fired one low-velocity round through the barrel which

performed the fire-lapping.

I inserted the bore guide into the action, then again

using USP Bore Paste™ ran an impregnated tightly fitting

patch back and forth through the bore 20 times.

This cleaned any powder residue and fouling from the

bore and prepared it for a second low-velocity lapping shot.

After performing the lap/shoot process for 5 shots, I

thoroughly cleaned the barrel using solvent and dry patches. This

removed any residual lapping compound in preparation for the

next finer compound.

The photo

above shows a recovered lapping bullet.

You can see the dark areas caused by lapping the lands

and grooves in the bore.

Now I

impregnated a clean patch with J-B® Bore Bright #083-065-100

that I purchased from Brownells which has a finer grit and

performed the hand lap/fire lap sequence another five times as

before, then thoroughly cleaned the bore again with solvent

and patches.

Finally, I

performed the same hand lap/fire lap process another five

times using the ISSO bore cleaner which has the finest grit.

This process performed the final polish of the chamber

throat and bore. The

bore was mirror bright and smooth and was now ready for full

pressure loads, and the new throat was polished which will

prevent excessive fouling.

Lapping

the Muzzle

The last

thing I did just to make sure I hadn’t picked up any nicks

or burrs on the muzzle crown was to lap the muzzle.

This removes those nicks and burrs and makes the ends

of the lands and grooves sharp and even which also enhances

accuracy. I put

some 400-grit lapping compound on the end of a brass muzzle

lap I purchased from Brownells #080-764-350

attached to a variable speed drill.

With the drill running at about 500-700 RPM I touched

the ball end of the lap to the muzzle at the angle shown in

the above photo and rotated the drill through 360-degrees

keeping the lap at the same angle.

I did this for about 1 minute making sure I kept

rotating my drill in a circular motion.

I cleaned

the excess lapping compound off the muzzle and ran a cleaning

patch through the bore from breach to muzzle.

As you can see in the above photo, the muzzle had a

bright ring around the inside and the lands and grooves were

nice and sharp.

Taller

Front Sight

The ’03-A3 is designed to hit 5-inches high at

200 yards using M2 ball ammo, but I wanted to be dead on at

100 yards with a dead-center hold.

I did some quick ballistic calculations and found that

I would have to drop the shot 4.7-inches to be on at

100-yards. Since I

couldn’t lower the rear sight any more, I would need to have

a taller front sight. I

used my Front

Sight Height Calculator to determine that I would need to

raise the front sight 0.037-inches.

The standard front sight blade is 0.537” so the new

front sight blade would need to be 0.574”.

I scanned

the front sight blade into my PC, used CorelDRAW®

to trace around the image, then increased the height to

0.574”. I

exported the pattern to BobCAD-CAM

so I could create the tool code for my CNC mill.

I first rotated the pattern 90-degrees so the base was

vertical. This

would fit better in the one-inch wide 3/64” tool steel stock

I purchased from OnlineMetals.com

that I used to fabricate the new front sight blade.

Once the

new blade was completed I used a jeweler’s file to remove

any burrs. I

installed the blade in the front sight base and used a #52

drill bit to mark the location of the mounting hole, then used

a center-punch to make the mark deeper.

You can clearly see the mark in the above photo.

I used my mill/drill and the #52 drill bit to drill the

mounting hole.

After the

hole was drilled I bead-blasted and cold blued the blade.

I installed it in the front sight base using a 1/16”

roll pin because I didn’t have a solid pin to mount the

blade. The pin was

nice and tight so the blade didn’t move.

Refinishing

Stock

I decided to refinish the original stock and

hand guard rather than purchase new ones.

I’ve refinished a number of gun stocks and they come

out looking almost like new, although this one is pretty beat

up.

I

completely disassembled the rifle and removed all the metal

parts from the stock and hand guard.

I used Klean-Strip®

KS-3 Premium Stripper that I purchased from my local home

improvement store to remove the old finish.

This stripper is a semi-paste that adheres to the wood.

I applied the stripper with a brush, allowed it to set

for 15 minutes according to the instructions, then wiped it

off with a paper towel. As

you can see from the above photo, the first application

removed almost all of the old finish.

I applied a second coat of stripper and used a stiff

nylon brush to work it into all the crevices.

I again wiped it off after 15 minutes.

After the third application I soaked a green scrubbing

pad in mineral spirits and rubbed down the wood to remove all

excess stripper and completely clean the wood.

After the wood was stripped and cleaned it appeared

like someone tried to refinish this stock once before and did

a poor job of sanding. However,

many of the original cartouches became visible after I

stripped off the old finish.

After the

wood dried I applied a wet cloth to the wood and pressed a hot

iron to the wet cloth. This

process steamed out any dents from the wood.

If this was a collectable stock I would not apply steam to the

cartouches since they are stamped (pressed) into the wood, not

cut. I steamed the entire surface of both the stock and hand

guard three times to make sure I raised as many dents as I

could, then set them aside to dry.

I took an

old stock I had in the shop and drilled a few holes in the

butt to get some walnut shavings.

I put the shavings in a mortar and pestle to grind them

into a powder. I

mixed the powder with some wood glue to make a paste and used

the paste to fill some of the gouges in the wood.

After the glue dried I sanded the filled spots, then

sanded the entire piece with a 220-grit sanding pad.

I used a pad so it would conform to the shape of the

wood.

I applied

my favorite stain, Minwax®

Gunstock #231, then wiped off the excess with a clean

cloth. I allowed

the wood to dry overnight.

After the

stain had been drying for about 8 hours I applied a coat of Minwax®

Clear Satin Fast-Drying Polyurethane to all the inside

areas of the stock and hand guard.

This will prevent moisture from getting into the stock

which can lie against the metal receiver or barrel and cause

rusting and pitting. I

have seen this condition in other military surplus rifles.

Once the

stain was dry I applied three coats of Birchwood

Casey® Tru-Oil®. Tru-Oil®

provides a durable, easy to repair finish that I use on all my

gunstocks. I

allowed each coat to dry for 6 hours.

After each coat was dry I burnished the surface with a

nylon stocking. I

don’t usually use steel wool because it can leave steel

filaments behind in the wood.

Repairing

Cracked Stock

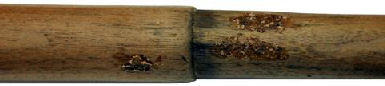

The stock

was cracked from the magazine cutoff detent back to the wrist;

but it was only cracked on one side.

I couldn’t open the crack far enough to put in any

glue so I decided just to use pins.

I took a

1/16” brass rod and threaded it with a 4-32 die.

I threaded enough so I could cut two pins.

I used a

#44 drill bit and drilled a pilot hole in the stock.

I made sure I didn’t go through the bottom of the

stock.

I applied a

clamp to the stock to keep the crack as tightly closed as

possible. I cut a

piece of the threaded rod long enough so I could insert it

into the chuck of my variable speed drill.

I applied some epoxy to the threads of the pin and used

the variable speed drill at a very low speed to screw the pin

into the hole.

I carefully

trimmed the pin flush with the wood.

I touched up the wood with sandpaper, stain, and finish

to match the rest of the gun. After the glue dried on the

first pin I performed the same process to a second hole

drilled from the bottom of the stock.

Hopefully the crack will not spread any more.

Result

The above

photo shows the result of all my work.

The stock was in pretty bad shape to begin with, but it

now has a very nice finish, and as everyone keeps telling me,

it has character. All

the external metal has been refinished and everything

functions as it should.

You can

still see a small spot of stainless steel where the old barrel

was tack-welded to the receiver.

As mentioned before, this is covered by the stock so

will not show.

I left the

receiver weld alone where the original magazine cutoff was

welded. Because of

the different consistency and hardening the weld metal

parkerized differently than the rest of the receiver.

Ok, so how

does it shoot? Well

first of all, it kicked like a bolt-action .30-06!

I can shoot my M1 Garand all day with no problems, but

I needed to wear a recoil pad when shooting the ’03-A3.

This is why after so many years since high school I

never owned one! However,

with a brand new, lapped barrel and proper bench rest

technique, you can see the 100-yard result with the above

target. I am very

pleased with the result, and proud to own a piece of

U.S.

military history that I restored to shooting condition.

Final

Cost

$220

Rifle plus shipping

$

15 FFL

transfer

$264

New parts

$

55 Chamber

reamer rental

$

64 Parkerizing

kit

$

63 Action

wrench head

$681

Total cost

I already

had most of the tools and supplies mentioned in this article

which kept my costs low, so the prices shown above are what I

actually spent out-of-pocket.

Summary

So why go through all the trouble and expense

of converting this drill rifle into a shooter when I probably

could have purchased a shooter for about the same price from a

gun show? First of

all was the challenge of the project and doing the work.

Part of the pleasure was doing the work myself and

seeing the result.

Second of

all, my rifle now has a brand new barrel and refinished parts.

Even if you could find a new, never been fired ‘03-A3

it would cost upwards of $1,500+ whereas I spent $681 for

parts and tools including the price of the rifle.

A gun show rifle wouldn’t have a new barrel or new

finish.

Best of all

I now have a functioning

Springfield

1903-A3 for my collection that will last for thousands of

rounds. I know I

probably won’t come close to putting a thousand rounds

through this rifle, but I do enjoy seeing those longing looks

from fellow shooters when I take it to the range.

So the next time I participate in a bolt-action

military rifle side match, guess which rifle I’ll be taking

along!

I also want

to express my thanks to Ray Brandes for his excellent web site

and article on how to recover an ’03-A3 drill rifle.

His article and photos pointed me in the right

direction, and I was able to purchase an excellent example of

one of these deactivated drill rifles from him.

************************************************************

Calculating

Barrel Taper

Gunsmithing requires some math capability; especially when it

comes to measurement and dimensions.

I needed to calculate barrel taper so I could make a

tightly fitting aluminum bushing for my barrel vise.

My bushing

had to be 1 1/8” long to fit in the barrel vise so I made

two marks on the barrel just below the chamber swell that were

1 1/8” apart. The

barrel diameter at the two marks was 0.980” and 0.942”.

I made a drawing as shown above.

I moved

both vertical lines up until the bottom of the small vertical

line was at the end of the horizontal line.

This helped me to visualize what I needed to do.

So now I needed to know the length of the small

vertical section on the left.

I found this as follows:

0.980”

– 0.942” = 0.038”: difference

between large and small vertical lines

0.038” /

2 = 0.019”: 1/2

the difference because the small line is in the center of the

large line

So the

small line was 0.019”. I

drew a line from the bottom of the large vertical line to the

bottom of the small vertical line so now I had a right

triangle and I could use basic high school geometry to

calculate the angle. (High

school geometry; I can hear you readers groaning from here!)

First I

needed to find the length of the hypotenuse.

I’m sure we all remember Pythagoras’ theorem for a

right triangle; A2 + B2 = C2

where A and B are the sides of a right triangle, and C is the

hypotenuse. So now

I had:

0.019”

2 +1.125” 2 = C2 so solving for

C I got

C

= √ (0.019”

2 + 1.125” 2) or

1.1251604330050004029069759316584”

So now I

needed to find the angle indicated by the arc in the above

diagram. The angle

is represented by the Greek symbol theta ( ).

In high school geometry we learned SOH CAH TOA to

remember the relationships of the angles and sides of a right

triangle. They

stand for: ).

In high school geometry we learned SOH CAH TOA to

remember the relationships of the angles and sides of a right

triangle. They

stand for:

SOH:

Sine = opposite over hypotenuse

CAH:

Cosine = adjacent over hypotenuse

TOA:

Tangent = opposite over adjacent

The side

opposite from angle( )

is 1.125” so I used the Sine function to find the angle.

I used the following formula: )

is 1.125” so I used the Sine function to find the angle.

I used the following formula:

Sine( )

= 1.125” / 1.1251604330050004029069759316584” so solving

for )

= 1.125” / 1.1251604330050004029069759316584” so solving

for  I got

I got

= arcsine(1.125” / 1.1251604330050004029069759316584”).

On the scientific calculator that comes on your PC

arcsine is the INV check box.

So the angle worked out to be 89.032o.

This was very close to 90o which I knew was

right, but would have been much too large to make my bushing.

The two non-right angles of a right triangle equal 90o

so I subtracted 89.032o from 90o which

gave me 0.968o.

This was the angle I used to make the bushing.

= arcsine(1.125” / 1.1251604330050004029069759316584”).

On the scientific calculator that comes on your PC

arcsine is the INV check box.

So the angle worked out to be 89.032o.

This was very close to 90o which I knew was

right, but would have been much too large to make my bushing.

The two non-right angles of a right triangle equal 90o

so I subtracted 89.032o from 90o which

gave me 0.968o.

This was the angle I used to make the bushing.

My high

school math teachers would be so proud!

|