Restoring

a Corroded Lever-Action Rifle Lever

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

Many of us who participate in Cowboy Action Shooting like to

wrap leather around the bottom of the lever of our

lever-action rifles to soften the sharp contact with our hand.

Unfortunately, the leather we use is often chrome

tanned. Chrome-tanned

leather leaves tanning salts behind which will corrode metal,

even if you thoroughly oil the leather.

Leather that will sit against metal – like holsters

– should be vegetable-tanned.

Marlin®

1894 Cowboy

I have a

Marlin 1894 Cowboy rifle in .45LC that I purchased used many

years ago. The

previous owner had wrapped the lever with leather; you can see

the resulting corrosion in the above photo.

The resulting pits left sharp edges, not to mention how

ugly it looked. A

new lever costs about $60.00 but I restored my existing one

for much less.

Polish

out the Pits/Corrosion

Like with

most things in life, preparation is everything.

I made sure my rifle was unloaded, then I removed the

corroded lever. First

I polished out all the corrosion and pits.

I took 150-grit sand paper wrapped around a bastard

file to aggressively sand the sides of the lever.

By doing the top and bottom of the sides I ensured they

remained flat and parallel.

Then I took a 220-grit polishing stick (www.BorideAbrasives.com)

to remove the sanding marks.

Finally I took 400-grit wet/dry silicon carbide sand

paper, then 600-grit wrapped around the bastard file to final polish the metal.

For the

wide part of the lever I removed the corrosion by shoe-shining

first with the 150-grit sand paper, then final polishing by

shoe-shining with 220-grit, then 400-grit, and finally with

600-grit wet/dry sand paper.

Cold

Bluing

Now that the metal is prepared I needed to clean and degrease

it to remove all of the residual oil and sanding dust.

First I put on a pair of vinyl gloves so the oils from

my hands wouldn’t contaminate the clean, bare metal.

Then I used acetone and cotton swabs to degrease the

exposed metal.

I recently

found a cold blue product called Rugged Gun Blue available

from Shooter Solutions™ (www.ShooterSolutions.com).

This is probably the best cold blue I have ever worked

with (refer to my product review article Shooter

Solutions Rugged Gun Blue).

Because this product uses acid to react with the metal

I continued to wear the vinyl gloves.

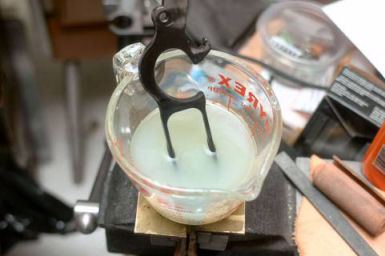

Note:

The solution is milky because I have been using it and

it has some impurities in it.

I purchased

two 4-ounce bottles which I poured into a glass measuring cup.

I dipped the lever into the Rugged Gun Blue and allowed

it to soak until it turned dark blue/black.

The exposed metal only required a few seconds to change

color. Because

Rugged Gun Blue uses acid, if you leave your part in the

solution too long it will start to eat away the metal.

I removed

the lever from the cold blue solution and placed it under

running tap water to remove the excess acid.

This step is necessary to dilute and remove all the

excess acid and stop the bluing process.

I used a hair dryer to remove the water, then applied

gun oil to the entire lever.

As you can see from the above photo the lever came out

almost factory new.

Summary

This is an easy restoration that the home hobby gunsmith can

perform to bring your lever-action rifle back to looking

almost factory new. The

polishing and preparation work took most of the time, but the

results were worth it. Not

only was the cost of materials far less than the cost of a new

lever, but I have the pride of doing the work myself.

|