Installing a Lanyard Ring on a 1911

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

From The Mexican Revolution 1910-20,

by P. Jowet and A de Quesada,

Illustrated by Stephen Walsh, Osprey Publishing

Introduction

John Moses Browning developed the M1911 handgun which was

adopted by the military in 1911. Per military

specifications he included a lanyard ring on both the pistol

and magazines to prevent cavalry soldiers from losing them

while mounted on horse-back. The officer on the far left in

the above drawing has a lanyard looped over his left

shoulder and connected to the loop on his M1911.

The

original model of 1911 had a smooth, flat mainspring

housing. When the gun was modified into the M1911A1 the

mainspring housing was arched with grooves. The arched

mainspring housing causes the gun to be tipped up in the

hand.

In this

article I’m going to discuss two methods of adding a lanyard

ring to a 1911; purchasing a new mainspring housing with the

lanyard ring already installed, and installing a lanyard

ring in an existing mainspring housing.

Purchasing a New Mainspring Housing

This method is the easiest because it is strictly replacing

a part. Personally I prefer a flat mainspring housing and

all of my 1911s have one. My Rock Island Armory M1911A1

came with a grooved, flat mainspring housing, but I wanted

the lanyard ring for authenticity. I purchased a smooth,

flat mainspring housing off of ebay which fit my RIA M1911A1

perfectly. In case you’re wondering, I slam a magazine home

with the heel of my hand; the lanyard ring never touches my

hand.

Adding

Grooves to the Smooth Mainspring Housing

I prefer

a grooved mainspring housing so I got out my 20 lines per

inch checkering file I purchased from Brownells

# 080-310-401 to add vertical grooves. I put the

mainspring housing in my vise and used the bronze vise jaws

as a guide. Notice in the above photo how the mainspring

housing is deep in the jaws. I grooved the center of the

mainspring housing keeping the edge of the file against the

vise jaw, and filed until the file wouldn’t cut metal

anymore. I cleaned up the grooves with a triangular needle

file.

I moved

the mainspring housing up so the surface was exposed. I

rotated my checkering file so I could add grooves to the

edges. The checkering file in the above photo is actually

tipped down. Although the mainspring housing is flat from

top to bottom, it is curved from side to side. I again

cleaned up the grooves with a triangular needle file. If I

had wanted to checker the mainspring housing, I would have

used the 20 LPI checkering file and filed at right angles to

the vertical grooves making nice, square points.

After the

grooves were cut to my satisfaction I bead blasted it to

remove the old finish, then Parkerized it to match the rest

of the gun. The result looks original.

Installing a Lanyard Ring in an Existing Mainspring Housing

This method is by far the most difficult because it requires

precise machining. However, rather than replacing a custom

or special mainspring housing, this method allows me to keep

it, especially if it is custom and matches the gun.

Besides, I got to do some real gunsmithing!

Karl

Lippard Designs sells the lanyard ring and retaining roll

pin on ebay. He also provides a copy of the M1911A1

mainspring housing mechanical drawing. Unfortunately, it is

a copy of a copy of a copy, etc. so it is somewhat difficult

to read. Fortunately Rio Benson of Benson Consulting, LLP

created a full set of M1911A1 drawings which you can

download

here. Page 30 has the exact same drawing, but much

clearer. I will not include the drawing in this article

because you can download it yourself.

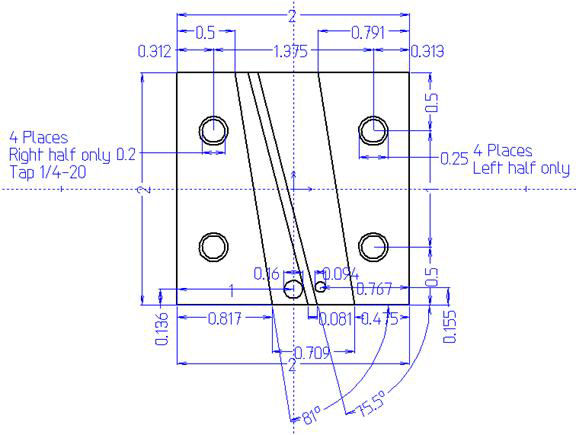

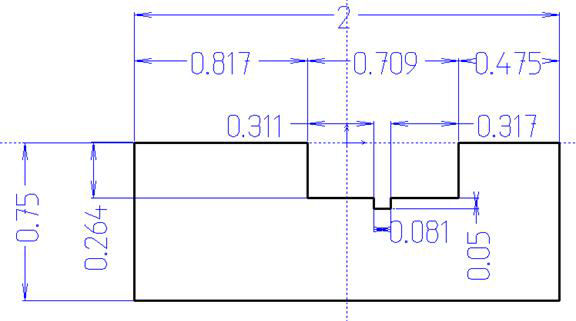

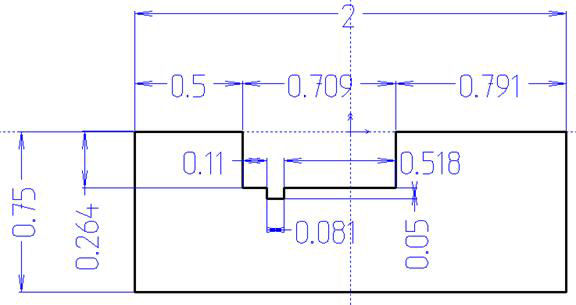

Manufacturing a Jig

I wanted to be able to mill/drill the holes accurately and

be repeatable so I designed a jig using CorelDraw v12 and

BobCAD-CAM v20. I used the dimensions from the M1911A1

mainspring housing drawing to design the jig. The drawings

below show the specifications for the jig. I never took

mechanical drawing in school so I probably haven’t followed

established guidelines, but all the numbers are there.

I have

trouble visualizing a three-dimensional part from a set of

drawings so I developed a 3D rendering to show what the

final jig half would look like. The right half has four

holes 0.200” in diameter which are tapped for 1/4-20

screws. The left half is a mirror image of the right half,

and has four holes 0.250” in diameter for 1/4-20 screws.

These screws hold the two halves together to hold the

mainspring housing in place for milling and drilling.

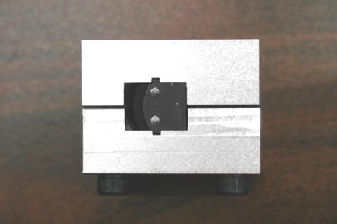

The jig

is designed so the base of the mainspring housing is

parallel to the milling table. This is because the holes

for the lanyard loop need to be perpendicular to the base.

The cutout is wide enough to accept both flat and arched

mainspring housings.

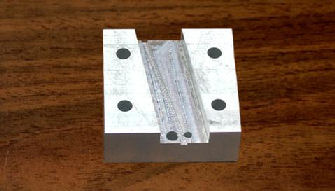

I had

some 3/4” aluminum stock so I milled two 2” x 2” blocks. In

each block I milled the design you see in the above

drawings. The width of a mainspring housing is 0.538-inches

so I milled each block 0.264-inches deep; a little less than

half. This is so when I install the mainspring housing in

the jig and install the four hex-head screws, the mainspring

housing won’t move. I also milled the holes for the two

retaining pins so the mainspring housing would be aligned

properly.

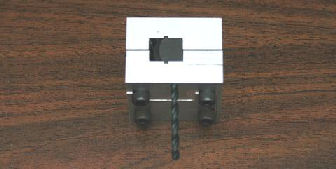

As you

can see from the above photo the jig holds both a flat, or

arched mainspring housing. I purchased a 5/32” drill bit to

act as an alignment pin when setting the mainspring housing

in the jig. This fits through the retaining pin hole in the

mainspring housing. I also purchased a 3/32” drill bit to

drill the hole for the lanyard ring retaining pin.

Milling

the Holes

I took

the original Rock Island Armory flat mainspring housing that

came with my gun and mounted it in the jig. I used the

5/32” drill bit to align the mainspring housing with in the

jig. I tightened the screws so there was an equal gap on

both sides of the housing. This ensured the jig was square

with the mainspring housing.

I mounted

the jig onto my CNC milling machine table so that it was

square. I installed a 3/32 square end milling bit and

positioned it 0.358” from the front edge and centered on the

base of the mainspring housing. I milled two holes 0.1065”

in diameter, 0.325” apart and 0.270” deep.

I

installed the lanyard ring in the holes, then used my bench

top mill/drill to drill the 3/32” retaining pin hole using

the jig as a guide. Drilling the hole also drills a notch

in each leg of the lanyard ring which keeps the ring in

place when the pin is installed. I installed the provided

3/32” roll pin in the retaining pin hole I just drilled.

Conclusion

It is much easier to replace a part than to modify an

existing part, but now that I have a jig I can add a lanyard

ring to any existing mainspring housing.

Addendum

11/05/2015

For the same price as one pre-formed lanyard ring I

purchased a one-pound coil of 37 gauge (0.106) steel music

wire from

MSC Industrial Supply Co. part number

31980964. This gave me about 34-feet of wire which

would make hundreds of lanyard rings. I purchased steel so

it would take bluing or Parkerizing to match the original

finish on the mainspring housing. They also sell this wire

in stainless steel part number

31981194.

The above

figure shows the dimensions of the lanyard ring. The

distance between the two legs is 0.219” so I used a 7/32”

drill bit to form the loop.

I cut

about 2 1/2“ of wire and held it in the flame of propane

torch until the middle became bright red. I then forged the

loop around a 7/32” drill bit to form the loop. Because the

wire was so thin it cooled fairly quickly so I had to reheat

it 3 or 4 times to get the shape I wanted.

I cut the

ends off using my Dremel tool with a cutoff wheel. I

polished the loop with 400-grit wet/dry sand paper to remove

any carbon and blemishes from the metal.

I had

a blued, checkered, arched mainspring housing in my parts

bin so using my jig I installed my homemade lanyard ring

onto that mainspring housing. I cold-blued the ring to

match the housing. I fixed the loop in place with a 3/32”

roll pin I took from my black roll pin set I purchased from

Brownells

#080-518-000. By removing the roll pin I can also

remove the lanyard ring and return the mainspring housing to

its original form. The only reason I installed the ring

in this arched mainspring housing was to see if I could make

the loop myself, and to test my jig and process a second

time. Everything worked as designed and I now have a couple

of spare mainspring housings with a lanyard ring.

|