Fitting

a 1911 Thumb Safety

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

A couple

of years ago I built a 1911 .45 using an 80% frame.

I hand fitted all parts to produce an accurate,

functioning pistol. However,

I’ve always wanted to install an ambidextrous thumb safety

on this gun. Although

this article is for a non-ambidextrous safety, the process

is the same.

Preparing

the Safety Preparing

the Safety

To begin, I removed all parts from the frame except for the

trigger and magazine release.

First, I made sure the back of the safety was

perfectly flat with no raised casting marks.

I filed any raised edges with a jeweler’s file.

Note in the photo how I had to polish off the raised

edge around the outside of the safety.

Fitting to the Frame

I installed the thumb safety so that it was flat against the

frame. I moved the

safety up and down to see if it would rotate freely in the

safety cutout slot in the frame.

My safety did not rotate freely and bound on the frame.

First, I

looked in the frame for any burrs that might be blocking the

safety. I found

one, which I filed off with a jeweler’s file. First, I

looked in the frame for any burrs that might be blocking the

safety. I found

one, which I filed off with a jeweler’s file.

The safety

still would not completely rotate so I had to increase the gap

between the flat rear of the safety and the safety lug.

I mounted the safety in my vise and with a square

jeweler’s file with a safe edge carefully filed the inside

of the lug in order to increase the gap.

I worked carefully and only removed a little metal all

around the inside of the lug.

I

re-installed the safety in the frame and again tried to rotate

the safety through its full travel.

Since it was still binding, I removed a little more

metal until it would rotate with no binding.

The top corner of the safety must at least reach the

bottom of the slide rail, or beyond, for the upper limit. I

re-installed the safety in the frame and again tried to rotate

the safety through its full travel.

Since it was still binding, I removed a little more

metal until it would rotate with no binding.

The top corner of the safety must at least reach the

bottom of the slide rail, or beyond, for the upper limit.

Fitting

to the Sear

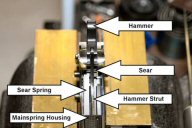

Now that the safety rotated freely, I removed it and

re-installed the sear, disconnector, and hammer.

Next, I installed the sear spring making sure that the

little tab at the bottom of the spring was in the slot in the

frame, and the flat at the top of the left most leaf was

against the bottom of the sear.

I installed the mainspring housing (MSH) making sure I

centered the hammer strut on the mainspring cap, then pinned

the MSH in place.

I cocked

the hammer and tried to install the safety.

It would not go all the way into the frame because it

was hitting against the sear.

I lightly filed the engagement surface with a safe-edge

file only 2 or 3 strokes at a time until the safety would go

in and I could engage it, making sure it blocked the sear.

I cold-blued the surface I just filed to protect it

from corrosion. I cocked

the hammer and tried to install the safety.

It would not go all the way into the frame because it

was hitting against the sear.

I lightly filed the engagement surface with a safe-edge

file only 2 or 3 strokes at a time until the safety would go

in and I could engage it, making sure it blocked the sear.

I cold-blued the surface I just filed to protect it

from corrosion.

In

the right photo, the safety is in the up or engaged position.

You can see how the round part of the thumb safety is

touching the rear of the sear, which prevents it from moving.

I

reassembled the gun, and with the hammer cocked and the thumb

safety engaged, I pulled the trigger…hard!

There should be no movement of the sear.

I then released the thumb safety to see if the hammer

would fall. It

should not, and it did not.

Fitting

Ambidextrous Safety

To get the right side of the ambidextrous safety to fit I had

to grind the right side of the hammer and sear pivot pins so

they were flush or below the frame.

I had to be careful that I did not allow the pins

to heat up or I could damage the heat-treating.

Finally, I

had to file a cutout in the right grip panel to accommodate

the leg on the safety. This

leg prevents the right side of the safety from falling off.

I filed a little at a time, then installed the grip

panel to see if the safety was binding.

I continued to file until the safety would not bind

with the grip panel installed.

Conclusion

Fitting a thumb safety to a 1911 is an easy process, as long

as I go slow when filing the engagement surface.

In my experience, once a thumb safety is fit to a

particular frame and sear, it may not work in another gun.

This is due to differences in tolerances.

If I move a thumb safety to another gun, I always

perform the safety checks to ensure reliability.

|