Reaming

a .45 ACP Chamber

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

I recently

purchased a Rock Island Armory 1911 .45 for my son which I

will give to him for Christmas.

The price was right, but like most things in life, you

get what you pay for! The

gun was functional, but quality and attention to detail were

poor. For example,

I had to replace the sear and disconnector to get a decent

trigger pull, and the feed ramp was milled off-center from the

frame.

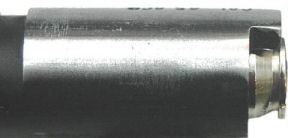

I took it

out to the range to make sure it didnít have any other

problems and noticed that the chamber seemed to be very tight

because the slide would not go into battery with many rounds.

When I returned home I took it into my shop and began

checking headspace. As

you can see from the above photo rounds would not fully seat

into the chamber. For

proper headspace, the case head should sit flush, or a little

below the rear edge of the barrel hood.

If I tried to press the cartridge deeper into the

chamber it would become wedged and difficult to remove.

My guess is that the manufacturer was using a worn-out reamer

that was undersized. The solution was to ream the

chamber to proper dimensions.

I purchased

a .45 ACP chamber finishing reamer from Brownells

#513-051-451. Although

this tool is somewhat expensive, I have used it a number of

times to correct the chambers in poor-quality, after-market

barrels.

I

disassembled the pistol and placed the barrel in a padded vise

with the chamber up (vertical).

I coated the reamer with cutting oil and placed it into

the chamber. Using

a tap wrench I turned the reamer clockwise (reamers and cutters

should never be turned backwards as this could damage the

cutting teeth). I

immediately could feel the reamer cutting steel!

I removed the reamer after about 5 turns; it is better

to go slow than cut too deeply.

The reamer teeth were filled with chips and steel dust

indicating that it was doing its job.

I cleaned the barrel and reamer with brake parts

cleaner and checked cartridge fit.

I continued

to cut and check cartridge fit until the reamer just touched

the lip in front of the chamber.

I didnít want to change the headspace; I just wanted

to ream the chamber. Now

cartridges seat fully and to the proper depth in the chamber

as you can see from the above photo.

Even rounds that I had set aside that wouldnít

chamber during the range session now chambered properly.

This pistol should now feed much more reliably.

|