PA-63

Feeding Problems

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers. All tools were

purchased from Brownells

unless otherwise indicated.

Introduction

A reader of the Kitchen Table Gunsmith and I have had an

interesting discussion regarding feeding problems with our

FEG PA-63 9mm Makarov pistols. When I made some

improvements to my PA-63 (refer to my article

Improving the FEG PA-63 9x18 Makarov) I discovered

that not all the Brown Bear jacketed hollow-point cartridges

I purchased were seated to the same depth which caused some

feeding problems. Reviewing that article, I discovered I

did not fully explain what types of feeding problems I

experienced, nor did I mention the cartridge overall lengths

of the Brown Bear ammo. My apologies to my readers; this

was an oversight on my part which I will correct with this

article. I did some further investigation into these

feeding problems, which I have detailed below along with

their solution(s). In the process, I also provided some

precise data.

Failure

to Feed (FTF)

A failure to feed (FTF) with a semi-automatic pistol can be

caused by several factors. I identified which ones affected

my PA-63 and eliminated them one-by-one until my pistol

would feed ammo reliably.

·

Bullet

Shape

Bullet shape is almost always the number one factor that

causes FTFs. The PA-63 is a military/police pistol that

was designed to take round-nose, ball ammo. Hollow-point

ammo will often cause feeding problems because of the flat

nose unless some changes are made to the gun.

·

Cartridge

Overall Length (OAL)

Cartridge overall length can also cause feeding problems.

A cartridge that is too long may get stuck in the magazine,

and if too short it could be released from the magazine too

soon and cause a jam.

·

Magazine

So many problems can be traced to faulty magazines, e.g.

follower spring too weak or too strong, feed lips too sharp

or damaged, feed lips releasing the cartridge too soon or

too late in the feed cycle, dirt in the magazine that slows

follower movement, or a damaged magazine body. These all

need to be checked and if present, eliminated. Worst case,

the magazine should be replaced.

·

Feed Ramp

If the feed ramp on the frame and/or barrel is damaged,

too rough, too steep, too shallow, or too sharp the

cartridge may not feed properly.

·

Recoil

Spring

A weak spring may not be strong enough to strip a

cartridge out of the magazine, and a spring that is too

strong wont allow the slide to come back far enough to

eject a spent case, or strip the next round out of the

magazine.

·

Hammer

Mainspring

If the hammer mainspring is too strong the slide may not

cycle completely and cause a stovepipe jam, or not strip a

cartridge out of the magazine. If too weak it could cause

the slide to excessively batter the frame, which is not good

for an aluminum alloy frame.

For a

semi-automatic pistol to function properly, all parts must

be balanced and work together.

Test

Ammunition

I used four different cartridges with different bullets to

troubleshoot my FTF problems. I wanted my pistol to feed

all types of ammunition.

·

Brown

Bear 115 grain Jacketed Hollow-Point (JHP) I purchased

500-rounds at a gun show because I wanted the heavier,

hollow-point bullet for personal defense. This ammo had

problems (see below), but apparently is no longer being

manufactured.

·

Hornady

Critical Defense 95 grain Flexible Tip (FTX) I purchased

this for personal defense to replace the Brown Bear ammo

because of its better expansion capabilities.

·

Fiocchi

95 grain Full Metal Jacket (FMJ) I purchased one box of 50

rounds strictly for writing this article.

·

Handload

Starline Brass, CCI 500 small pistol primers, Lee

365-95-1R hard-cast lead round-nose (LRN), 3.6 grains of

Winchester 231. I purchased brass and a Lee bullet mold for

writing this article. I already had the Lee reloading dies.

Magazine

Spring

My pistol came with one magazine. I wanted some spare

magazines so I purchased four from ebay. One of those

magazines never would feed the Brown Bear HP ammo

correctly. The magazines hold seven rounds, and when full,

the first round of the faulty magazine would nose-dive and

tip forward. Because the Brown Bear HP ammo has a flat

tipped nose, the edge of the nose would catch on the sharp

front edge of the feed ramp and prevent the slide from

moving completely forward into battery. None of the other

magazines had this problem. This was a good indication that

the magazine spring had probably become weak.

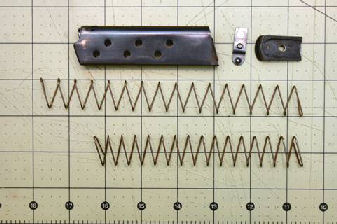

I

purchased a set of three extra power magazine springs from

Wolff Gunsprings for the Walther PP 7.65 and 9mm. Since

the PA-63 is an exact copy of the Walther PP this spring fit

perfectly. Notice in the above photo the original spring is

a lot shorter than the replacement, but they both have the

same number of coils. Unfortunately, during the live fire

test this magazine still failed with the Brown Bear

ammunition, but so did a good magazine. This is probably

because of the shape of the bullet nose, not necessarily the

magazine. This magazine will require more testing.

Feed Ramp

The feed

ramp was a bit rough and the front and side edges were

sharp. The flat, hollow-point nose of the Brown Bear ammo

would get caught on these sharp edges. I removed the

ejector which doubles as the slide lock by pressing down

on the retaining spring with a small flat-blade screwdriver,

and pulling the ejector out of the frame. I used my

high-speed rotary tool set to the lowest speed and a

cone-shaped Cratex polishing bit to gently round off the

sharp edges. Then I took a piece of 400-grit sand paper

wrapped around a pencil eraser and smoothed the edges. I

worked slowly and carefully because even though this is a

hard aluminum alloy, it is possible to remove too much

metal.

Bullet

Shape

As mentioned before, this pistol was designed for

round-nose, ball ammo. I had no feeding problems with the

Hornady Critical Defense loads because they are conical in

shape. I also had no feeding problems with the Fiocchi or

hand-loaded rounds because they both had round-nose shapes.

I had the

most feeding problems with the Brown Bear hollow-point

ammo. This was because the front of the hollow-point nose

was flat and had an edge. This edge tended to get hung up

on the sharp edges inside the pistol. Gently rounding the

sharp edges around the sides and front of the feed ramp

helped to fix this problem (see above).

Depth of

Seating

As mentioned in my previous article, I had problems feeding

the Brown Bear ammo because the bullets were not seated to

the same overall length (OAL). To my surprise, they

measured 0.955 0.972 cartridge OAL. So much for quality

control! Through trial and error, I discovered that if the

Brown Bear rounds were seated to a cartridge OAL of 0.965

or longer they would bind up in the magazine and cause

feeding problems.

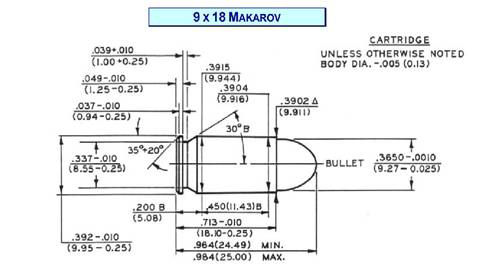

(Diagram courtesy Sporting Arms and Ammunition

Manufacturers' Institute, Inc.)

The SAAMI

specifications for 9x18 Makarov cartridge OAL is 0.964

0.984 inches, but this is for a round-nose, ball

cartridge. (My set of Lee loading dies shows 0.980 as the

maximum.) I set my 9x18 Makarov seating die to seat the

Brown Bear bullets to the shortest OAL of 0.955 so all the

cartridges would be consistent. Seating the bullet deeper

into the case prevented it from rubbing against the front of

the magazine and fixed some of the failure to feed

problems.

I wanted

to be sure my fix was not excessive. Seating a bullet

deeper into the case can increase pressure. With the Brown

Bear hollow-point bullet seated to an OAL of 0.955 I

extrapolated what the overall length would be if the bullet

was a round-nose. I took a photo of a Brown Bear cartridge

and overlaid it onto a photo of a round-nose cartridge. I

filled in the missing round-nose of the hollow-point bullet

in blue. With this crude method, it appeared that if the

bullet was a round-nose, the OAL would be 0.984 which is

the maximum OAL per SAAMI specifications. So not only was

my fix safe and within SAAMI spec, but it eliminated some of

my feeding problems with the Brown Bear ammo.

The

Hornady Critical Defense cartridges are seated to an OAL of

0.975. Because of their conical shape, I had no feeding

problems when hand-cycling from a full magazine or during

the live-fire test. I only fired 7 rounds because this is

expensive ammo to use just for plinking.

As a side

note, I have a Taurus 24/7 PT Compact Pro in .45 ACP. The

feed ramp on this pistol is very steep and wont feed most

hollow-point rounds because of the flat nose. The manual

says it is designed for round-nose, ball ammo, but what is

the point of making a compact pistol that wont feed defense

ammunition! Because of their conical shape, this gun had no

feeding problems with the Hornady Critical Defense rounds.

Because they feed in most firearms and have good expansion

capability, Hornady Critical Defense ammo has become my

personal defense ammo when I carry.

The

Fiocchi cartridges were seated to an OAL of 0.976. I had

no feeding problems with this ammo when hand-cycling from a

full magazine because of their round-nose shape. I also had

no feeding problems during the live-fire test.

I cast

about 100 bullets using the Lee 365-95-R1 bullet mold and a

hard-lead mixture. Out of the mold my hard-cast bullets

weighed 104-grains and measured 0.367 in diameter. I

lubricated the bullets with Lee Liquid Alox, which I hate to

use because it makes a sticky mess in my seating die, and it

takes time to wipe off the completed cartridges. I used

3.6-grains of Winchester 231 and seated the bullets to

0.976 OAL like the Fiocchi cartridges. I made sure to put

a slight taper crimp on the case to prevent the bullet from

being pushed deeper into the case during feeding. Again,

because of the round nose shape I had no feeding problems

when hand-cycling from a full magazine. After feeding, the

lead bullet showed a mark where it slid along the feed ramp,

but because of the taper crimp, the bullet did not get

pushed deeper into the case. I also did not have any

feeding problems during the live fire test.

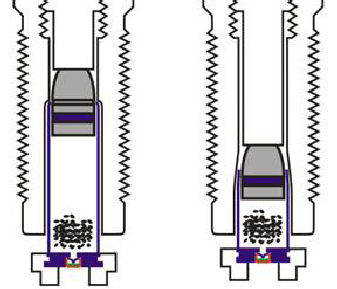

A quick

note about seating lead bullets into semi-auto cases: Most

modern seating dies also crimp the case. The die is

designed with a constriction part-way inside so when pushed

far enough into the die, the brass case meets the

constriction and is crimped against the bullet. Crimping is

an important step when loading ammunition. For revolver

cartridges, it prevents the unfired bullets in other

cylinders from backing out during recoil. If the bullets

protrude beyond the face of the cylinder the revolver will

jam. For pistol cartridges, it prevents the bullets from

being pushed deeper into the case during the feed cycle.

This can cause either feed problems, or excessive pressure,

or both.

Revolver-caliber seating dies use a roll crimp where the top

of the case is rolled into a crimp groove in the bullet.

Since most semi-auto pistol bullets headspace on the case

mouth, a roll crimp could cause headspace problems. Because

of this, pistol-caliber seating dies use a taper crimp where

the mouth of the case is squeezed just a bit tighter against

the bullet. This still allows the cartridge to headspace on

the case mouth, but prevents the bullet from being pushed

into the case during the feed cycle.

For a

pistol cartridge, when a lead bullet is being seated (pushed

into the case) at the same time the case is being crimped, a

small ring of shaved lead can be pushed ahead of the case

mouth. The cartridge now headspaces on the ring of lead,

which prevents the slide from going completely into

battery. Chamfering the inside of the case mouth will

not eliminate this problem. Jacketed bullets dont have

this problem because the copper jacket is harder than lead

and wont shave.

The way

to avoid this problem is to separate the seating and

crimping processes. If I dont have a separate crimp die, I

back out the seating die body so the crimp doesnt touch the

case mouth, then adjust the seating plug to seat the bullets

to the proper depth. After all bullets are seated, I back

out the seating plug, and then adjust the die body to crimp

the cases. As an alternative,

Lee Precision makes a factory crimp die for most

calibers. When I use my progressive press to reload pistol

ammo, the fifth station is a factory crimp die.

Live-Fire

Test

I took the various ammo to the range and tested them for

function and feeding. As mentioned in my previous article,

the Brown Bear ammo kicked like a mule, but the Wolff

21-pound recoil spring I installed help absorb some of that

recoil. This requires a little more strength to rack the

slide, but makes the gun a pleasure to shoot.

Brown Bear

Hornady

Fiocchi

Hand Load

All

rounds were fired at 7-yards (21-feet) from a rest and were

accurate at that distance. The Brown Bear and my hand loads

were right on for elevation, the other two were high. The

Brown Bear cartridges experienced two failures to feed, one

with the bad magazine even with the new magazine spring, and

one with a good magazine. I brought another magazine with

me and the other rounds fed perfectly from that magazine.

Since I am still having feeding problems with the Brown Bear

ammo, I may try to use my kinetic bullet puller to bump out

the bullet and reseat to 0.960 0.963 cartridge OAL and

see if I still have the feeding problems.

Summary

My FEG PA-63 experienced feeding problems caused by bullet

shape, bullet seating depth, and a bad magazine. I

corrected each of these problems, and rounded and polished

the sharp edges on the feed ramp to increase feeding

reliability. Every gun is different and may experience all,

some or none of the problems mentioned here.

Based on

what I saw on

Gunbroker.com, the FEG PA-63 seems to be a popular

little pistol, and is available in both 9mm Makarov and .380

Auto calibers. Because of its popularity, the prices just

keep going up. The miniscule sights are terrible,

especially for us folks with older eyes, and unfortunately

Novak is no longer producing their .380 sights. If I was to

purchase another PA-63, I would probably fabricate taller

and wider dovetail sights like a 1911, and mill dovetail

slots in the slide for the new sights.

This gun

is my summer-time carry gun, with which I would trust my

life. Its fun to shoot, and with a little bit of analysis,

elbow grease, and parts replacement, it is now very

reliable.

|