Improving the FEG PA63 Trigger

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers. All tools were

purchased from Brownells

unless otherwise indicated.

Introduction

My Hungarian-made FEG PA63 in 9mm Makarov caliber is my

summertime everyday carry (EDC) gun. It is small,

lightweight, easy to conceal and carry, and packs a bit more

punch than the .380 Auto (9mm Kurz). Hornady makes their

Critical Defense cartridge in 9mm Makarov which is my chosen

defense cartridge for this gun. I have two articles on

improving the PA63 and correcting ammo feeding problems

(refer to my articles

Improving the FEG PA63 9x18 Makarov and

PA-63Feeding Problems.) Now itís time to continue

the improvements and do a little trigger work.

I

significantly lightened the double-action trigger pull by

installing a 19-pound Walther PP hammer spring. Wolff

Gunsprings is now selling hammer and recoil spring packs for

the FEG PA63 9x18 Makarov only. These are available

directly from Wolff

https://www.gunsprings.com/FEG/PA-63/cID1/mID20/dID103

but are

also available from MidwayUSA.com.

https://www.midwayusa.com/product/1004183399?pid=437714.

I havenít

tested these springs, but I believe the PA63 9mm Makarov

would need the lighter hammer spring and heavier recoil

spring as I installed in my own pistol.

WARNING: These Wolff PA63 spring kits are only for the 9x18 Makarov

caliber, NOT the .380 Auto caliber.

Disassembly

The PA63

is an exact copy of the Walther PP so I referred to books

and YouTube videos on how to disassemble the Walther PP.

The most difficult part to remove was the pesky U-shaped

sear or cocking lever/cocking piece as it is called in the

schematics. This is where most of the work needs to be

performed, so it must be removed from the frame. There are

some things you need to be careful of during disassembly:

1.

The

ejector has a small spring on top that sits in a groove in

the frame. Use a small, thin, flat-blade screwdriver to

depress the spring and lever it out of the frame. Now you

can pull the ejector from the frame. Donít lose the spring!

2.

Remove

the trigger pivot pin first before removing the trigger bar.

3.

The

cocking piece is probably the most difficult to remove; at

least it was on my PA63. Hereís the trick:

a.

Knock off

the left rear corner of the cocking piece. I used a fine

sanding drum on my Dremel tool while the piece was in the

gun. This makes it easier to remove.

b.

Remove

the two pivot pins from either side of the cocking piece.

c.

Rotate

the cocking piece so the left side falls inside the hammer

pin opening.

d.

Looking

at the right side of the frame, position the cocking piece

so it is at the bottom of the kidney-shaped cut in the

frame.

e.

Rotate

the cocking piece to the left and up so the left leg clears

the kidney-shaped cut and you can remove the cocking piece

from the frame. Knocking off the corner should make this

easy.

Springs

If your

gun is like mine, it was probably built with a truck

suspension spring installed in the magazine release. I

replaced it with a 1/4Ē length of 0.118 diameter spring from

Brownells spring kit #69

025-069-000. I used a Cratex tip to polish the inside

of the magazine release hole in the frame. I applied SFL-0

grease to the outside of the magazine release, then

reinstalled it in the frame with the lighter spring. This

made the magazine release easier to manipulate, but still

held a magazine in place.

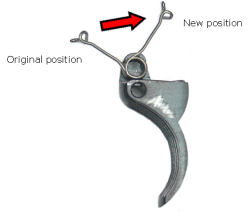

To

reduce the trigger pull I bent the trigger return spring

90-degrees to the rear of the trigger as shown in the above

photo. Donít go too far or the trigger will not return

properly, and the trigger bar/disconnector will not

function. My trigger return spring required that I move it

90-degrees. Yours may require less, but it should be bent

to the final position shown above. The shiny area on the

left side of the trigger was caused by a burr in the frame.

I took a flat jewelerís file and removed the burr. The burr

was causing the trigger to drag which affects the trigger

pull.

Sear Work

Makarov.com has a write-up on how to perform a trigger job

on the PA63, which was my primary source; here is the link:

http://makarov.com/tech.html.

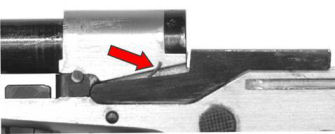

You

should see a wear mark on the top of the cocking piece (left

arrow above). This is where the hammer dog rides in

double-action mode. This area and the underside of the

hammer dog need to be polished. Use a ceramic stick or fine

Arkansas stone.

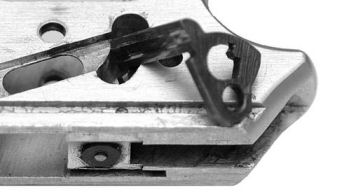

On the

underside of the cocking piece is the single-action sear

ledge. I first polished this ledge with a fine ceramic

stone. The stone is square so I would not change the

angle. The ledge on my pistol measured 0.038-inches, which

is why the single-action trigger pull had so much creep. I

stoned the top of the ledge to reduce it to 0.020-inches.

I

reassembled the pistol using SFL-0 grease on the magazine

release, cocking piece single and double-action sears, and

on the slide rails. I lubricated all pins with FG 68 oil

(refer to my article

The Search for the Perfect Firearms Lubricants), and

wiped down the gun with a gun rag impregnated with FG 68

oil.

Results

The single-action trigger breaks at 3-lbs, 10-oz., and the

double-action trigger breaks at 9-lbs, 13-oz. The

double-action trigger pull is very smooth, but the

single-action still has a bit of creep which means the sear

ledge could be reduced a bit farther, but I think Iíll leave

it alone. The magazine drops with a firm, but not heavy

press of the magazine release. Overall, I am pleased with

the continued improvements to my FEG PA-63 9mm Makarov

pistol.

A word of

caution here; you may have an original PP, PPK or PPKS or a

clone built by any one of several manufacturers. Some of

the springs and parts pictured here for my FEG PA63 may be a

bit different for your gun so work slowly and carefully.

Addendum

9/27/19

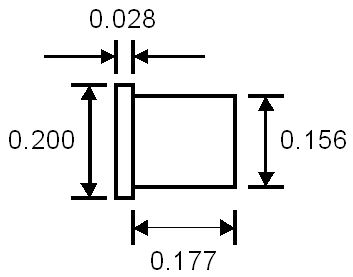

I wanted

to try fabricating new sear rivets (cocking piece pivot

pins) as suggested by the Makarov.com article. My pins fit

loosely in the frame and would fall out without spring

pressure on the cocking piece. Donít ask me how much

swearing I did during reassembly each time a pin fell out,

rolled off my worktable, and fell onto the floor!

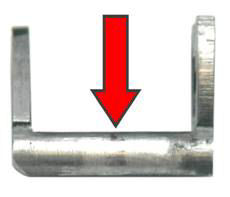

I

carefully measured the existing pins, the holes in the

cocking piece, and the holes in the frame. I wanted the

pins to fit snuggly in the frame but not require that they

be press-fit, and still have the cocking piece rotate

freely. After measuring, the new pins would have the

dimensions shown above. I took a piece of 1/4ď round steel

stock and turned the two pins on my lathe. I cleaned and

cold-blued the pins with Brownellís

Oxpho-Blue.

Because

the hole in the frame was the same size as the hole in the

cocking piece, I couldnít get a snug fit in the frame. So,

I used a trick I learned working on 1911 hammer pins.

I took

the large taper alignment pin from the alignment pin set I

purchased from Brownells

#080-645-000, chucked it in my drill, and turned the end

against a rotating cutoff wheel in my Dremel tool until the

end came to a point.

I

installed one pin through the cocking piece and into the

frame and set the head of the pin on a steel surface; I used

a small anvil, but a vise jaw will work. I put the

sharpened alignment pin through the hole in the other side

of the frame to punch the center of the installed pin. This

spread the pin so it would fit tightly in the frame, but the

cocking piece still rotated freely. I removed that pin with

a punch, then staked the other pin in place, then installed

the first pin. Now both pins fit snuggly into the frame,

but the cocking piece still rotates freely.

Staking the pins changed the amount of take-up in the

double-action trigger, but did not change the trigger pull

weight. At least those pins wonít fall out during

disassembly/reassembly anymore!

|