Improving the Kel-Tec Sub 2000 Trigger

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Kel-Tec

makes a very innovative rifle called the Sub 2000.

This carbine-style rifle folds in half for easy

transport and takes the same magazines as your favorite

pistol. However,

this little rifle requires some minor work to improve its

overall function.

Disassembly

I first make sure the rifle is unloaded and no magazine is

installed. Then I

disassemble the rifle according to my article Kel-Tec

SU 2000 Disassembly.

Relieving

the Magazine Well

My Sub 2k takes Beretta magazines because I have a Beretta

92FS, but both the factory Beretta and after-market magazines

fit very tightly. I

relieved the magazine well on both receiver halves as follows:

I completely disassembled the rifle, then wrapped a piece of

400-grit wet/dry paper around a magazine. I carefully

sanded the rails inside the magazine well on each side of the

receiver. I put

the receiver halves together with the screws and magazine

catch to test for functioning. I

also beveled the edge of each magazine where it met the

magazine catch.

Working

the Hammer and Sear

Caution: This

procedure requires special tools.

Unless you are familiar with working with hammers and

sears, please do not attempt these procedures.

Required

Tools

Please do not attempt to cut/polish the hammer and sear mating

surfaces without the correct tools.

Without the correct tools you could round the surfaces

making them unsafe and/or inoperable.

I used the following tools to modify the hammer and

sear.

As

mentioned on the KTOG bulletin board ( http://www.ktog.org

) the sear of the Sub2k rifle is set at a positive angle, i.e.

when the sear moves forward it actually has to force the

hammer up against the hammer spring.

This is one reason for the very heavy trigger pull.

Also, the sear-to-hammer mating surface is about

.060 deep. In

this procedure I will zero the sear angle and reduce the

amount of sear-to-hammer mating surface.

Please be aware that the only way to change the angle

of the hammer and sear mating surfaces is with the proper

tools. Ok, enough

harping!

Hammer/Sear

Basics

How

the hammer and sear mate is critical to firearm safety, and

directly affects trigger pull.

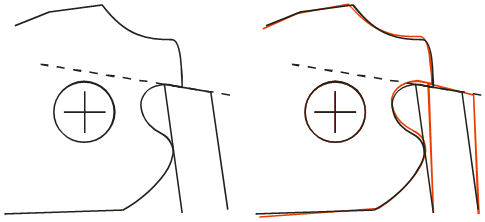

The above figure shows a hammer and sear with a

positive engagement angle.

(The angle in these diagrams has been exaggerated for

clarity.) The

angle is in front of the hammer pivot point.

When the sear rotates toward let off, it pushes the

hammer up against the hammer spring making the trigger pull

heavy, but very safe; the hammer cannot accidentally fall off

the trigger.

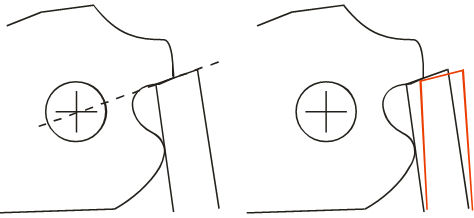

If

the sear angle is in line with the hammer pivot point, this is

a sear angle of 0o as shown in the above figure.

Notice that when the sear rotates, the hammer stays in

place. This makes

for a light, smooth trigger pull.

The depth of the sear engagement controls creep and

let-off. The

deeper the sear engagement, the more drag or creep in

the trigger because it takes longer for the hammer to release.

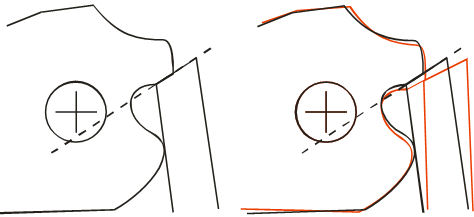

If

the sear angle is behind the pivot point, this is a negative

engagement angle, as shown in the above figure.

This results in a very light trigger, but it can be

unsafe as jarring the firearm could cause the hammer to slip

off of the sear. The

pressure of the hammer pressing against the sear could cause

the sear to move forward releasing the hammer.

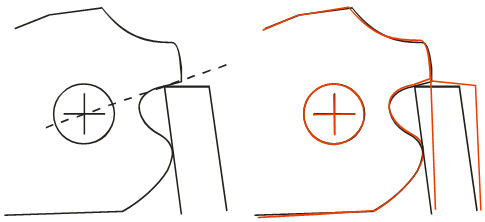

It

seems that the Kel-Tec Sub 2000 hammer is at 0o but

the sear is not. This

still causes some hammer push through, causing a heavy

trigger. However,

there are enough manufacturing variations that you need to

check each individual hammer and sear.

Measuring

Angle of Hammer Mating Surface

I

set the hammer on top of a straight edge so the mating surface

was parallel with the edge.

If the straight edge bisected the middle of the hammer

pivot hole, the angle was already set to 0o.

If the hammer was not already at 0o then I

would have to correct it first before working on the sear.

Setting

Sear Angle to 0o

This procedure requires the Power Custom Series I stoning

fixture with MKII adapter.

As mentioned before, the sear is cut at a positive

angle causing hammer push through.

I verified this by assembling the hammer bushing,

hammer, and sear into the left receiver half.

While looking through the safety hole and putting

pressure on the hammer with my right index finger, I rotated

the sear away from the hammer and felt for hammer movement.

I needed to adjust the sear until it did not push the

hammer against my finger.

I performed these steps only after verifying that the

hammer angle was 0o.

I

installed the MKII adapter on the Power Custom Series I

stoning fixture and align the 0o mark to the line

as described in the fixture instructions.

Then I set the stone guide elevator until the stone was

perfectly flat with the mating surface as described in the

fixture instructions. If

there was no hammer push through, I polished the sear with the

coarse then fine stones.

If

there was hammer push through I marked the sear mating surface

with marking fluid. I

then moved the elevator up 4 clicks (1 click is about 1/2o).

I used a square, coarse stone or coarse ceramic stick

and stoned the sear surface until enough smooth surface was

showing that will be engaged by the hammer mating surface.

I tested hammer/sear function again looking to remove

any hammer push-through. I

repeated the adjust and polish steps until there was no hammer

push through then final polished with a square, fine stone or

fine ceramic stick.

Hammer

This procedure required the Power Custom Series II stoning

fixture with universal adapter.

When performing this process, I frequently checked for

fit by installing the hammer, hammer bushing, and sear into

the left receiver half with no springs.

I visually checked the hammer and sear mating surfaces

by looking through the safety hole in the left receiver half.

Before working on the hammer I needed to modify the

Series II stoning fixture and universal adapter.

Modify

the Series II Stoning Fixture

In order for the Series II stoning fixture to work with the

Kel-Tec Sub 2000 hammer, it must be modified by drilling and

tapping a third mounting hole so the stoning guide can be

moved farther to the right.

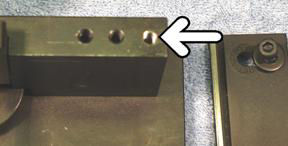

I

first moved the stoning guide to the existing far outside hole

and locked it in the far right position using the Ό x 20 hex

screw. I drilled a

13/64 hole into the upright at the far right side of the

stoning guide adjustment hole.

After I removed the stoning guide I tapped the new hole

with a Ό x 20 tap. I

set and locked the stoning guide onto the stoning fixture

using this new hole.

I

installed the universal adapter onto the fixture and used a

high-speed rotary tool with a cutoff wheel to cut a slot in

the adapter mounting screw.

This will facilitate adjusting the adapter.

Modifying

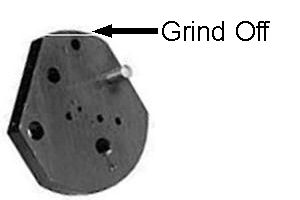

the Universal Adapter

The universal adapter that comes with the Series II stoning

fixture needs to be modified to work with the Kel-Tec Sub 2000

hammer.

I

ground the shorter, round radius flat so there was enough

metal left for the small set screw to function.

This was necessary so the stone did not interfere with

the adapter when working the hammer mating surface.

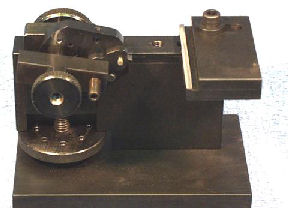

With

the B side facing me and the ground edge at the top, I

installed a .125 pin into the top hole, then installed the

hammer onto this pin so the mating surface was on the right.

I then installed a .187 pin into the larger hole to the

right of the hammer and allowed the hammer to rest against

this pin.

I

installed the adapter onto the stoning fixture so that the

ground edge of the adapter was to the right, then installed

the clamp block so the hammer did not rotate.

The

coarse and fine stones I purchased from Brownells especially

for this jig were different widths so I had to adjust the

stoning guide so both would fit.

I decided to drill a .094 hole in the adapter in line

with the alignment mark. This

will allowed me to duplicate the setup if I wanted to work on

another Kel-Tec Sub 2000 hammer.

Setting

Hammer Angle to 0o

I measured the hammer angle as described before.

If the straight edge bisected the middle of the hammer

pivot hole, the angle was already set to 0o.

I

set the elevator up 52 clicks from the bottom and adjusted the

jig so that the fine stone was perfectly flat against the

hammer mating surface as described in the instructions.

This was the reference point.

If

the hammer was already set to 0o I used the fine

stone to polish the mating surface.

If the hammer angle needed to be adjusted, I moved the

elevator up or down accordingly.

3 clicks is about 1o of change.

I used the

India

stone to cut the new mating surface and again used a

straight edge to check for an angle of 0o.

Once I achieved 0o I polished with the hard

Arkansas stone.

Reduce

Hammer Mating Surface

From the factory, the hammer mating surface is about 0.060.

I wanted to reduce it to 0.020 - 0.030.

This wont lighten the trigger pull, but it will make

it crisp.

Using

a caliper I measured from the front of the mating surface to

the top of the hammer. It

should be approximately 1.247.

I wanted to remove .030 - .040 so the result

should be between 1.207 - 1.217.

Using

a high-speed rotary tool with a cutoff wheel I carefully

removed metal from the front of the sear mating surface.

I checked frequently for fit.

I made sure to leave enough metal so the sear would

positively and safely catch the hammer.

I stopped removing metal when the measurement was

reduced to 1.206. I

then beveled the edges of the hammer mating surface to reduce

the width. This

will result in a crisp trigger pull.

I

installed the hammer onto the Series I 10/22 adapter and

installed the 10/22 adapter on the Power Custom Series I

stoning fixture so that the front of the sear mating surface

was on top. I

stoned the front of the sear mating surface so that it was

square. I was sure

to maintain a round radius.

I then carefully stoned the front edge of the sear

mating surface to break the burr raised by the grinding.

I lubricated the hammer and sear mating surfaces with

good quality gun oil.

I

reassemble the rifle and tested for functioning.

My rifle now has a safe, crisp, smooth trigger pull

that breaks at 6 pounds. This

is very acceptable for this type of rifle.

Addendum 2017

There is a company called

M.CARBO that is manufacturing after-market parts for the

Sub 2000 such as spring and trigger kits. If you don't

have the jigs and don't want to do the work yourself, click

on the link above and check them out.

|