These

instructions came from a number of cowboy shooters including

Blackhills Blackie, Eight Bits (me), Calaveras and Jess

Money; my thanks to them for their work and willingness to

share. My comments are in red.

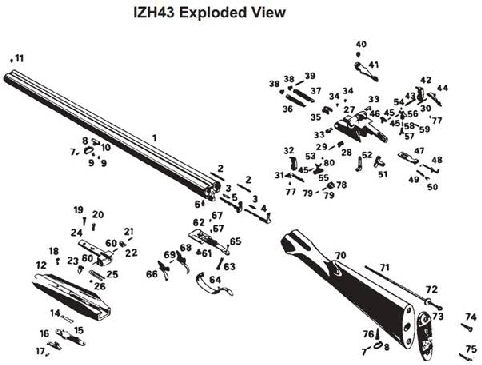

This is a rewrite of my original article; but this time I

have included photos and a schematic with parts list.

Since I took the photos after I completed the work the

springs in the photos are not the original springs. Much

of what is written here came from two sources on the

Internet:

http://marauder.homestead.com/files/TuneBaik.html

http://www.hobbygunsmith.com/Archives/Nov03/Scattergun.htm

Introduction by Jess Money

Before you even attempt to work on the internals of this

firearm, imagine this shotgun as two separate guns having

one butt stock and one fore end; because that's basically

what you're getting ready to find.

There is

a left side and there is a right side and even though in

appearance the hammers, sears, cocking rods and cocking cams

look alike, they each fit one side of the receiver only.

The exception could be the cams themselves, especially if

someone has modified them previously. Even more reason to

put them back on the side they came from.

First

off, set up your work area for a "receiver left side”

component section and the same for a "receiver right side"

component section. This is a good idea if you're taking the

receiver apart for the first time or the umpteenth time.

The parts look almost identical and you want to put parts

back in the same way they came out. Keep your work area

clean. It will become cluttered soon enough so anything

unnecessary will be in your way. Put your soft drink or

coffee in a separate area. You don't want to spill liquid

here.

(I clean the plastic containers Chinese soup and foods come in and

use them for gun parts when working on guns. Or you can

purchase some plastic containers with lids from the grocery

store.)

The

Tuning Process by Blackhills Blackie

1)

The first

thing you need to do is remove the barrels, stocks, and

trigger guard. Take off the butt pad. There is a hole in

the rear of the stock and a screw at the bottom of that

hole. This screw holds the stock in place. Remove it and

pull the stock free from the receiver.

2)

To remove

the trigger guard, remove the trigger guard screw located at

the rear of the trigger guard. Rotate the trigger guard

counter clockwise until it comes off.

3)

Remove

the screw that holds the threaded connector (stock mount

“T”) and remove the threaded connector.

(This threaded connector only goes

on one way. I put the screw back in the hole to help me

remember the correct orientation.)

4)

Next

remove the screw at the bottom of the receiver that holds

the bottom plate in place. This can be tight, so use a well

fitting screw driver. (I placed the

received in a padded vice and had to use an impact driver to

remove the screw the first time. The second time I removed

the screw I used a socket wrench.) Lift the bottom

plate loose from the receiver. You may have to gently pry

this part away from the receiver.

(Be careful not to lose the sear springs.)

5)

There is

a pin that passes through the sears from one side of the

receiver to the other. Tap this out with a punch and

hammer. Remove the sears and the two sear springs.

6)

There is

another pin that holds the hammers in the same fashion.

This needs to be removed so the hammers can be taken out.

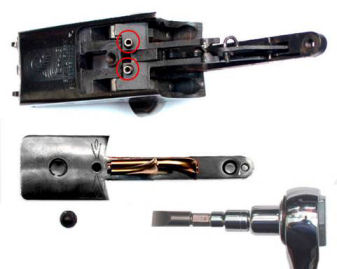

(Do not touch the rebound springs

embedded in the hammers! Pay attention to which hammer is

left and which is right. I marked mine as you can see in

the above photo.)

7)

On the

front of the receiver, there are two cams that do the

cocking when you open the action. These are held in place

by another cross pin. Remove this pin and the cams.

8)

After

this is done, you can remove the hammer spring assemblies by

pulling them out through the holes in the front of the

receiver. (Pay attention to the

orientation of each assembly and note which is left and

which is right.)

9)

To change

the springs, you will need to compress them while you tap

out the pin that holds the cap onto the end of the spring

shaft. Wrap a rag around them so they don't go flying. I

sacrificed a kitchen fork to use as a tool to compress the

springs. (don't tell my wife) (I

didn’t plan on saving the springs so I used a Dremel tool

with a cutoff wheel and cut through them. This made

removing the pin much easier.)

10)

(Use stock Ruger Vaquero hammer

springs and see if the barrels stay open. If not cut

1/2 coil at a time until they will stay open. This is

a trial and error process.) They may look a little wobbly, but stuff

them into the cleaned out/polished bores.

(To make reassembly easier, I ran a 1/16” drill bit through

the holes in the rod and end cap, just to ream out the

burrs. The pin slid back in with only finger pressure.)

11)

To change

the release lever spring, remove the lever by tapping the

pin out that holds the little block inside the receiver that

the lever actuates. (The automatic

safety connecting rod should now fall out. Leave it out if

you want to disable the automatic safety.) I used a

hammer spring (main spring) from a 1911 semi auto that was

cut to the same length as the Baikal spring. Smooth the cut

end with a file.

(If the release lever won’t function with the 1911 spring, proceed as

follows:)

a)

Remove the locking lever screw from the top of the lever.

b)

Use a punch to drive out the locking bolt lever, then remove the

locking lever.

c)

Remove the safety mechanism by removing the two pins, one in the

receiver, and one through the thumb piece. Be careful not

to lose the detent ball and spring.

d)

Remove the locking bar.

e)

Polish the top, bottom, and sides of the locking bar, and its groove

in the receiver. Be sure it slides freely in the groove.

f)

Polish the locking bolt lever and its bore in the receiver. It

should rotate freely.

g)

Remove burrs and polish the bottom, and round front of the release

lever. It should rotate freely.

h)

The cam of the locking bar lever rides in a cut in the locking bar.

All mating surfaces need to be polished and any burrs

removed. This was why mine wouldn’t work with the 1911

spring.

i)

Reassemble the locking bar, safety mechanism, locking bar lever,

locking lever and screw. The head of the release lever

screw is milled at an angle to match the angle of the

release lever. Tighten the screw until the head is flush

with the top of the release lever. Tightening the screw

will press the release lever onto the locking bolt lever.

Do NOT over-tighten this screw or the release lever will

bind against the receiver.

12)

Now would

be the time to remove the safety connecting rod if you want

to disable the automatic safety. The safety will still

function but it has to be activated manually. This part

should have fallen out when performing the prior step.

13)

While the

gun is apart, you should take the opportunity to sand and

polish all internal parts until they all move freely. If

you skip this step, you could have parts that stick because

of the lighter springs. I used 600 grit emery cloth and

oil. It does a nice job and doesn't remove much metal.

After all

this is done, you won't believe the difference in the gun.

It will open easily, stay open for faster reloads, and have

a lighter trigger pull. Take your time and try not to get

frustrated. It took me several times disassembling and

reassembling my gun to get it the way I wanted it. What I

have listed here is the result of this. Let me know if

there is anything else I can do.

Blackhills Blackie

1.

The

safety can be converted so it is a manual safety instead of

an automatic safety. It will still work, but only when you

put it on "safe" intentionally. When you take it apart, you

will see a lever that actuates the safety when you open the

action. You can remove this lever and the safety will come

on when you put it on, and stay off when you switch it off

like your rifle.

2.

The stock

springs cause the barrels to want to close part way when you

open it up. Pushing to the left on the lever keeps it

open. After you replace the springs with the lighter ones,

you won't have to do this.

3.

You're

right about the gun being dirty inside. Mine was. Besides

grease, there was saw dust and other stuff in there.

(The ones I’ve worked on were

clean. Better quality control?)

4.

Brownell's sells a mercury-filled tube that you can install

in the stock. It is supposed to reduce recoil

significantly. I haven't tried one, but I'm planning on

getting one. My wife is going to start shooting the cowboy

matches with me and I don't want her to have to deal with

the kick of this thing the way it is.

5.

As for

light recoil shells, Winchester makes a light recoil 12

gauge shell. They are called "Low Recoil, Low Noise Target

Load". The part number on the box is AA12FL8. They are

commonly called "Feather Lights", but I didn't think this is

their actual name. Cheaper Than Dirt seems to have the best

price on these.

6.

The

chambers on my gun didn't really need honing. The shells

dropped out the first time I used it. But I did polish them

a little. I took a bore mop and rubbed some automotive

polishing compound on it, chucked it up in a drill, and ran

it in and out of the chambers for a while. I just can't

leave things alone. I also use silicone spay lubricant in

the chambers before each shoot. The shells fall out.

Comments

from Calaveras

Now here are some things I ran into. First, the stock

retaining screw was seriously tight. It's slotted, so I

found a long-shank screwdriver that fit that had a hex at

the top of the shank (snap on). I put the stock in a vice

padded well and pushed hard while turning the wrench. It

broke loose. I believe the wood had swelled and had that

screw at about 100 lbs of torque. If this hadn't worked I

was prepared to rig up a hand impact driver that I could hit

with a hammer.

I had no

problem driving the pins out for the cocking cams, triggers

and sears. Observe closely, the way they came apart, mark

them if you have to. When I was reassembling, I had to

refer to the manual that came with it a couple of times. I

had the barrel upside down that the stock retaining screw

goes into and couldn't get the stock to go on all the way.

I used

600 grit emery cloth and oil and slicked up the sides of the

hammers, sears, triggers and the cam that the release lever

uses to move the locks. I cleaned and inspected as I went.

The 1911 hammer spring worked neat. What I did was take the

pin from the cam and just took the stock spring out and cut

the same length of the 1911 spring. I have enough spring

left over to do about two more levers. There is no need to

remove the lever or anything.

The

cocking springs are the reason, the foul thing wouldn't open

far enough. You can hold them in a vice and either vice

grip or use a fork to compress the springs. The pin pushes

out with a nail. I didn't even have to drive it. When you

get the vaquero springs, cut them 1/4 longer (2 1/2“ in

length) than the Baikal springs. I then took needle nose

pliers and bent the end coil to the next one and closed the

diameter a bit to keep it close to the shaft at the hammer

end and filed it flat. I found that the vaquero springs are

easy to put together and pin the caps. I used a kitchen

fork and no problem. I got a little excited when I put the

setup in the bore; it felt like it was going to be too big.

Not so, once I got it seated it was fine. Make sure you

have left and right in the proper side.

I went

ahead and polished the receiver at the cocking spring where

the barrel hinges. I don't know if I needed to, but it was

rough, so I went ahead and did it.

Now for

my barrels, I removed the screw that retains the extractor

and found that I could not even pull it out with my

fingers. I inspected it and found the guide pin bent and I

straightened it, but it was still seriously tight. I

polished the pins a lot until I could slide the extractor in

and out with ease. I also polished up the sharp edges on

the extractor, not wanting to cut myself in the heat of

battle, trying to reload quickly.

I didn't

polish the chambers, as shells didn't stick in my SxS before

and I figured I could always do it later. Once I had the

receiver all back together and figured out why the stock

wouldn't slip all the way on. I sanded the stock on the top

to give the lever plenty of room and on the sides coming

from the receiver to just smooth it up a bit. I went and

sanded the whole thing and wiped on some Watco special

walnut stain I had around and it looks great. I put the

screw back in the stock, careful to make it not too tight

and the end piece.

Then to

try it. What a dream; opened easy, fell open all the way

with plenty of clearance for reloading and locked up tight.

Smooth, feels like a Browning. Took it out back and shot a

few. SOLD, it is a great gun, Russian commies or not and

every bit as nice as I could hope for. Now if you decide to

tackle it, I will be able to help you, so long as my memory

holds out.

Regards,

Calaveras

(Because of manufacturing differences, every one you work on will be

a little different. Be prepared to find things not listed

in this write-up.)

Comments

from Jess Money

You'll be removing and reinserting cross pins when you

remove sears, hammers and cocking spring assemblies so it's

important to have a 1/16" punch to start to drive with. My

punch is a Stanley and it looks like a yellow wooden pencil

made of steel. The actual 1/16" punch section is only 1"

long. Since the shotgun receiver is wider than that, you'll

need some slave pins to help completely remove the factory

cross pins from the receiver. I sacrificed some drill bits

for this and a 1/8" bit, a 3/32" bit and a 5/32" bit worked

fine for the job as slave pins. (I

use the Replaceable Pin Punch Set

#080-507-000

from Brownells. The pins are long enough that you don’t

need slave pins.)

Once you

remove the barrels, look at the two protrusions on either

side at the front of the receiver. These are the cocking

cams and you'll be removing the smallest of all the cross

pins that hold them in place. A suggestion here, when the

time comes to remove the cams and hammer spring assemblies:

drive the cocking cam pin from one side into the receiver

body just far enough to completely clear the cam and then

remove the cam and spring assembly. Then tap the pin back

in from the other side just far enough to clear the other

cam and remove that cam and spring assembly. Once that

spring assembly is removed, tap the cross pin back in flush

with the receiver. That's the safest place for it.

Although

not absolutely necessary, a small table mounted metal vice

with a 3" jaw opening will be really helpful when driving

the pins, removing the trigger guard, removing screws and

then replacing them again. It helps too when you're filing

and polishing the inside of the receiver. I used some scrap

flooring linoleum and glued a piece to each side of the

metal jaw with Elmer's Glue and that has been working well

for over a year. A small vice will be sufficient because

we're not talking about putting a tremendous amount of

pressure on the receiver, just enough to hold it firmly.

Besides, everyone should have a vice around the house for

other projects.

A

jackscrew is just the ticket for lifting the floor plate

from the bottom of the receiver. I found an SAE stove bolt

in my parts drawer that worked just right. Be sure to

remove the long screw from the T shaped fixture at the very

back that holds the tang and floor plate together and serves

as a receptacle for the butt stock bolt. Once the floor

plate is off, you're looking into the boiler room of the

shotgun. Look immediately for two small coil springs

located in the top of each sear. They sit in a blind hole

and they press on the floor plate to return the sears. They

should be heavy with grease. Take these two small springs

and place them where they won't get lost.

Now,

notice anything? Look closely. That's right! You are

looking at the bottom of the shotgun. So, things are a bit

different from this view. Left is right and right is

left. Repeat; left is right and right is left! When

you begin removing parts make sure you place your parts in

the correct component areas you made and be sure you

remember that left is right and right is left.

Now that

the sear return springs are safely put away, let's remove

the sears. Those long legs on the rear are what the trigger

tabs actuate. Using your 1/16" punch, tap the cross pin as

far as the punch will reach. Stop before you get to the

area of the punch that is wider than 1/16". Use your

properly fitting slave pin, or drill bit, to drive the pin

the rest of the way out. Remember left is right and right

is left and put the sears in their proper component area.

When each pin is removed, mark the end you drove from with a

colored pen, china marker or chalk and put this end in first

when you replace the cross pin. A jar lid would be a safe

place for your cross pins. They will roll around on a bench

and are easily lost!

Now, for

the hammers. Look closely how the hammers sit in their

slots in the receiver. They are aligned almost vertically

on the cross pin. Remember that because it's important.

Again, using the 1/16" punch, tap the cross pin as far as

the punch will safely go, then use the properly fitting

slave pin to drive the pin the rest of the way out and put

the hammers in their proper component location.

Now go

back and pick up one hammer. Look at it closely. Turn it

over, upside down and sideways. Notice that part of the

lower section has been milled away and in that section

you'll see a hole that has been drilled there. It actually

looks as if the hole was misaligned because there is an open

section in that oddly drilled hole. Inside that hole is a

small spring that resembles a hair pin. In the paragraph

above, it was suggested you remember the vertical alignment

of the hammers. It's important to remember the odd hole in

the thin part of the hammer, too. Notice that on the end of

each cocking rod there is a small round section, similar to

a short piece of a nail, that is 90° to the rod. This piece

fits into the odd hole in the thin part of the hammer and

the small hairpin in the hole helps secure the rod into the

hammer when cocked. Neat, huh? So that's why the hammers

are vertical in their slots. You've got to make sure you

press the hammers forward to engage the rod when you're

aligning the hammers on reassembly. Not hard to do but has

to be done. Remember, the cocking rods and cams must be

reinstalled and pinned before you can replace the hammers

Now is

the time to tap the last small pin in the front of the

receiver that holds the cocking cams and rods. Notice how

the cams fit into the slots in the cap of the cocking rods.

You can completely remove this cross pin, or follow my

suggestion about partially removing it. Remove the cams and

cocking rods and place them in their proper component

location. You now have an essentially bare receiver. A

tooth brush, small steel or copper brush can be used to

remove debris left from the factory. An air compressor or

even canned air will help blow junk from the receiver after

using the brushes.

Taking

one component group at a time, examine each piece for wear

areas, places that the piece makes contact with the frame

and polish the devil out of both sides of each piece of each

component group. Polish the receiver where the parts rub,

if possible. Anything that looks like it should be polished

should get the works. We're speaking of polishing, not

grinding. There may be some areas on the insides of the

receiver that could use a few strokes with files of

diminishing coarseness but for the most part we want to use

400/ 600 grit paper or a hard Arkansas stone on our

component pieces. A light coat of Rem Oil or similar on the

component pieces won't hurt, but don't overdo it.

After

you're satisfied with your polishing efforts, reassemble the

receiver in reverse order you disassembled it. When

replacing the pins you'll need to use your slave pins

again. Be patient and the gun will go back together just

fine. You may have to jiggle a bit here and twist a bit

there and in general hold your mouth just right to align the

floor plate into place. Remember to be sure the stock bolt

section on the T should point upward. Remember, since we're

still working upside down, when the butt stock is replaced

it will be upside down, too. DO NOT over tighten the floor

plate screw. You may wish to replace the cocking springs

later or reverse your trigger positions. Snug tight will do

for the screw. DO tighten the butt stock screw securely.

Good luck

and have fun!

Jess

Money

Note: After making these changes I used my shotgun for a cowboy

match every month for about seven years and never had a

problem. When disassembling the gun to take these photos I

noticed it was pretty dry inside. I lubricated all friction

points with Brownells Action Lube Plus

#083-050-002 which is a synthetic grease that I use for

the internals of all my firearms.

(Courtesy EAA Corporation)