Making

Custom Handgun Grips

by Roy Seifert

Click here to purchase a CD with this

and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered

trademark of their respective manufacturers.

Introduction

I’ve always had the desire to make my own custom handgun

grips. I decided

to start with 1911 grips because they’re somewhat flat and

fairly simple to make. Using

CorelDRAW®, my CAD/CAM

software BobCAD-CAM and

my MAXNC 10 CL

CNC hobby mill I felt I could design and create my own grips.

Jig

Before

beginning the design work on my grips I needed to build a jig

to hold the wood. I

purchased a piece of 3/4” x 3” x 12” aluminum from Online

Metals.com to use as the jig.

I milled six holes along the center length of the jig;

the two 0.201“ outside holes spaced 6.25“ apart I tapped

for 1/4-20 bolts. These

are used to hold the scale for drilling holes.

The next two holes are 0.258” drilled completely

through the metal with a 0.3752” countersink 1/4” below

the top. This

holds a 1/4-20 set screw for T fittings that hold the jig to

my mill table. Finally

the two inside 0.212“ holes spaced 3.074” apart I tapped

with a 1911 grip bushing tap.

I install a 1911 grip bushing in these holes to hold

the scale for final shaping by the mill.

After I

milled the holes I took a 3/16” square end bit and milled a

center mark on the jig. This

allows me to center the milling head each time I reinstall the

jig.

Designing

the Grips

I have the excellent book "The

U.S.

M1911/1911A1 Pistols: A

Shop Manual Volume 2" by Jerry Kuhnhausen.

Page 79 contains detailed measurements for 1911 grips

which I used for my design work.

I used

CorelDRAW® to do my initial design work.

First I scanned a pair of factory grips then traced the

outline. I used

the Kuhnhausen manual to adjust the dimensions and create the

3-dimensional profiles. These

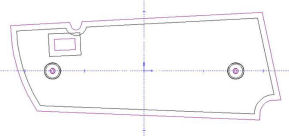

3-D profiles are located at either end of the grip outline.

The two red crosses at the bottom of each outline are

used to help me locate the bottom profile after I get it

rotated into the third (Z) dimension.

The small square below the left mounting hole of the

right grip is for the gap for the right part of an

ambidextrous thumb safety.

The line along the top of the left grip is for milling

a notch to allow for the plunger tube.

The two mounting holes are exactly 3.074” apart along

the center line. The

shape and 3-D profile of the grip is always with reference to

this center line.

Next I

exported each grip pattern as a drawing .dwg file, which I

then imported into the CAD/CAM program.

The CAD (computer aided design) part of the program

allows me to create a 3-D part.

I created all of the tool paths for the bushing and

screws holes, cutouts and notches, and the final outline.

Because I could use a 3/16” square end bit for all of

these cuts, the tool paths had to be offset by half of the

thickness of the bit, or 3/32”.

First I

created the tool paths for all of the holes.

I did the bottom holes first; the countersink for the

grip bushing, then the hole for the bushing itself.

At this time I also created the tool path for the

cutout on the right grip for the ambidextrous safety, and the

plunger tube notch on the left grip.

Next I created the tool paths for the top holes, which

are for the grip screw heads.

In the above figure, the purple lines are the tool

paths.

Now I

created the tool path for the outline of the grip.

Again, this tool path had to be offset by half of the

thickness of the 3/16” bit.

So far this

has been fairly easy because I’m working with a flat,

two-dimensional design. But

now I needed to create the three-dimensional shape of the

grip. I decided I

didn’t have to create a detailed 3-D shape with all the

notches and cutouts. Instead,

because I was going to cut the outline first I decided that I

only needed to create a general 3-D shape that followed the

contours of the grip.

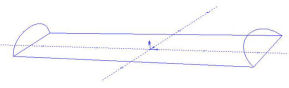

First I

rotated the top grip profile so it stood up straight; this is

now the top 3-D shape of the grip.

I rotated the bottom grip profile upright so it leaned

to the left by 45-degrees, then rotated it 12-degrees to match

the bottom outline. This

gave me the bottom bevel of the grip.

Using the software I connected the two 3-D profiles and

created a 3-D “skin” which was now the 3-D shape of the

grip without all of the notches and cutouts.

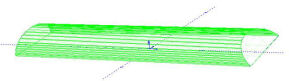

I created

the tool path for the 3-D shape based on a 5/16” ball end

bit. The tool path

starts in the center of the grip and cuts in a radial pattern

around the grip. The

3-D pattern is a little bit larger than necessary because I

designed the tool path to run off the edge of the grip and I

didn’t want the edge of the bit to remove any excess wood.

I also set the individual tool tracks very close

together so I could get a smooth grip with very few ripples,

which makes it easier to finish.

Scales

Creating a

grip begins with a blank piece of wood called a scale.

I found on the Internet some Brazilian blood wood that

makes beautiful, bright red grips.

This is more of a soft wood, like pine, rather than a

hardwood like walnut, but it has a very fine grain.

For 1911 grips I cut the blood wood into 3/8” x 2”

x 4 1/2” scales. I

take one side of each scale and sand it flat on my belt sander

using a fine-grit belt. This

is the inside of the grip that sets against the frame of the

gun.

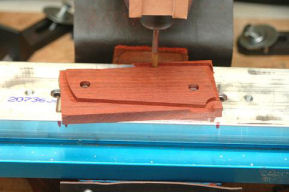

Step

1: Milling the

Bottom Holes and Notches

I position

the scale in the center of the jig and hold it in place with

brackets as shown in the photo.

I install the 3/16” square end bit and zero it to the

top of the wood. I

run the program that mills the grip bushing and bushing

countersink holes. If

this is going to be a right side grip, I also mill the

ambidextrous safety cutout.

If this is going to be a left side grip I mill the

plunger tube notch.

Step

2: Milling the Top

Holes

I remove

the grip and install the grip bushings onto the jig.

This keeps the scale properly aligned for all the other

operations. I turn

the scale over and install it onto the bushings and reinstall

the brackets. I

then zero the 3/16” bit to the top of the jig and mill the

two screw-head holes.

Step

3: Milling the

Outline

I remove

the brackets and install grip screws to hold the scale in

place. I now cut

the outline of the grip. When

this is completed I have a 3/8” thick grip that fits the

1911 frame, but it still needs to be milled to the proper

shape.

Step

4: Milling the

Final Shape

I install a

5/16” ball end bit, zero it to the top of the jig, and start

the final shaping program.

It takes about 90-minutes to mill the final shape of a

grip, but this is because I wanted the tool paths to be close

together so the result would be smooth.

Step

5: Engraving a

Design

Because I

have a CNC mill I can etch designs into the grip.

As with the grip itself, I first create the design

using CorelDRAW® then export the design to BobCAD-CAM.

With BobCAD-CAM I project the design along the curved

surface of the grip. This

now becomes the tool path for engraving the design.

I use a

0.02” ball end bit to engrave the design.

Because this bit is so small I remove 0.0005” with

each pass down to a total depth of 0.008”, and move it very

slowly.

Step

6: Final Finish

I mount a

completed grip onto a small piece of aluminum onto which I

have installed two grip bushings.

I hold this piece of aluminum in my hand so I can run

the grip over a piece of 150-grit sand paper to remove any

milling marks and make it smooth.

I final sand the grip first with 400-grit, then

600-grit sand paper.

Now that

the grip is finished I apply 3 coats of Birchwood

Casey® Tru-Oil® to all surfaces and inside all of the

holes. I allow

each coat to dry for 6 hours before applying another coat.

As you can

see from the photo, the results are spectacular.

These are a set of grips I made for my son engraved

with his initials.

|