Fabricating

a Custom Front Sight

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Navy

Arms 1892

My long-time shooting buddy, Jon (a.k.a. “Lone Star”) has

a beautiful stainless steel Navy Arms replica of a

Winchester

1892 in .45 Long Colt caliber with a twenty-inch octagon

barrel. He

recently installed a tang peep sight which he uses as a ghost

ring by removing the aperture.

Unfortunately, he couldn’t get the new sight low

enough, which meant the rifle was shooting high.

It was alright for “minute of cowboy”, but he

wanted to be able to adjust the sights to hit to point of aim.

Since the peep sight couldn’t go any lower, that

meant we would have to raise the front sight.

The rule is; move the rear sight in the same direction

you want the bullet to go, move the front sight in the opposite

direction you want the bullet to go.

I have a

number of spare sights in my parts bin, but none of them would

fit. Apparently

Navy Arms used a non-standard dovetail that was wider than

3/8. Jon also

mentioned that he didn’t necessarily need a beaded front

sight. So I

decided to fabricate a square post front sight for him using

my MAXNC 10

CL CNC hobby mill.

Fabrication

I ordered a 1/8” x 3/4” x 12” piece of steel bar stock

from OnlineMetals.com,

my favorite place to purchase metal.

This would become both the base and front post for the

new sight.

I

used CorelDRAW® to design

the pattern for the sight base and post.

I like using CorelDRAW® because I have greater design

control, and I am very fluent in its use.

In the above figure the square in the middle of the

base is for the notch that will hold the post.

Now

for some math; I used my Front

Sight Height Calculator to calculate the increase in front

sight height. Jon

needed to move his shots down 6-inches at 25-yards.

The increase in front sight height would be 0.170

inches. His front

sight measured 0.328” which meant the new sight would have

to measure 0.498”; which we rounded up to 0.500”.

His base measured 0.515” wide and the dovetail was

0.389” wide (much wider than a standard 3/8” 0.375”

dovetail) and the base thickness measured 0.113”.

0.500” – 0.113” = 0.337” which would be the

height of the new front post.

I also milled a notch in the base which allowed me to

keep the post straight when silver-soldering it to the base.

I wanted

the total height of the sight to be 0.500”.

Since the dovetail was 0.113”, that meant I needed

the front post to be 0.337” in height.

Remember, sight height includes the thickness of the

dovetail. Using

these measurements I created the machine “G” code for my

hobby CNC mill.

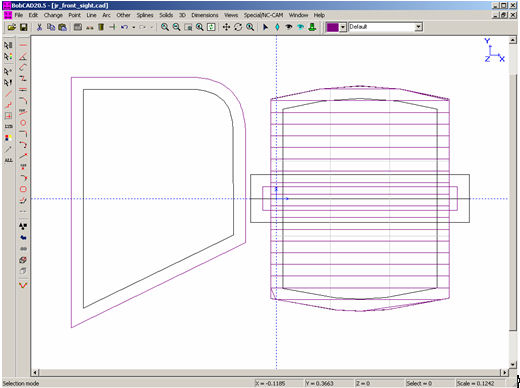

I exported

my design as a drawing .dwg file, which I imported into my

CAD/CAM software BobCAD-CAM.

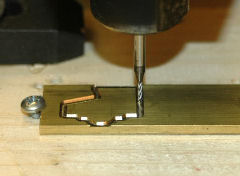

I planned to perform the milling with a 1/16-inch

square end bit, so I created the tool paths offset by 0.0313,

or half the diameter of the 1/16 bit.

The purple lines in the above figure are the tool paths.

For the post and base the tool path was offset to cut

outside; for the notch in the center of the base, the tool

path was offset to cut inside. The multiple lines

on top of the base were for milling the thickness of the base

down to 0.113".

Assembly

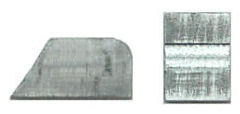

After the parts were milled they had some rough edges.

I took a flat jewelers file and some 400-grit wet/dry

sand paper to trim the flashing.

I used a Cratex bit and my high-speed rotary tool to

polish the sharp edges on the base.

Now I

assembled the two pieces by silver-soldering them together.

First I cleaned each surface to be soldered, held the

part with a pair of needle-nose pliers over a propane torch,

and when the metal got hot enough, tinned the mating surface

with the solder. The

part needed to be hot enough so the solder would melt, flow

and stick; if the part was too hot the solder would bead up

and run off, if too cool the solder wouldn’t melt.

While the solder was still molten I used a brush to

wipe off the excess solder.

Now that

each part was properly tinned I inserted the post into the

notch, held the parts together with pliers, then held the

assembly in the propane flame so the solder on the parts would

melt and hold them together.

I also ran a bead of solder along the joint so it would

flow down into the seam. You

can see the soldered seam in the above photo.

The metal turned dark when I applied heat to the

pieces. I allowed

the assembled sight to cool to room temperature without

artificial quenching. If

the part is cooled too quickly the silver solder can become

brittle and the part could come apart.

After the sight cooled I took a flat jewelers file and

removed the excess solder from the corner of the joint.

Milling

the Dovetail Angles

So now I

had an assembled sight, but the base was square; I still

needed to mill the angles for the dovetail.

I mounted the sight upside-down in my machinist vise on

my table-top mill. I

installed a 65-degree dovetail cutter I purchased from Brownells,

set the depth so the bottom of the cutter was riding on the

bottom of the post, then ran the cutter along the front edge

of the base thereby cutting the correct dovetail angle.

I cut the rear edge the same way.

Final

Finish

The sight was still discolored by the heat from the soldering

process, so I took the sight to my blasting cabinet and

beat-blasted it clean. The

bead blasting removed the discoloration and left an even, matt

finish.

Now the

sight was ready to be blued.

I’ve had great success using Van’s

Instant Gun Blue. This

is the best, and probably most difficult cold-bluing product

to use. It really

isn’t very “instant”!

This product produces the closest result to hot bluing

and I’ve discovered it is the best product to use for bluing

larger areas. Using

vinyl gloves so my bare hands wouldn’t touch the sight, I

thoroughly degreased the sight using acetone.

I poured some Van’s Instant Gun Blue into a small

aluminum pan and immersed the sight into the solution so that

it was completely covered.

After 5 minutes I removed the sight.

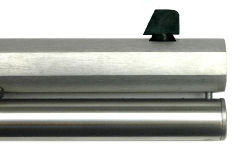

As you can see in the above photo the sight came out

with a deep, rich, even blue/black color.

I wiped the sight clean and coated it with gun oil to

stop the bluing process and to protect the sight.

I

used a 65-degree dovetail file to fit the new sight into the

dovetail on the barrel. Notice

how high the post sits above the barrel.

This was because I measured the thickness of the

original sight base instead of the dovetail in the barrel.

Marlin®

39A

Jon’s sight came out so well I decided to make one for my

Marlin® 39A .22 lever-action rifle.

Like Jon’s rifle, this rifle came with a bead front

sight which I wanted to replace with a square post.

Jon uses his rifle for Cowboy Action Shooting™ so he

couldn’t have any color on his sight.

On my sight I decided to put a vertical white line

which seems to be popular for ghost-ring sights.

Brownells

sells a post front sight with a white line in the center for

$30. Using parts I

had on hand mine cost much less.

I used the 1/8” x 3/4” x 12” piece of steel bar

stock for the post as I did with Jon’s rifle.

Brownells sells a 12-inch piece of 3/8” dovetail

blank which I used as the base; this way I didn’t have to

cut the dovetail angles.

The

dovetail for Jon’s rifle was cut into the barrel.

Barrel-mounted front sights use a longer dovetail;

Jon’s measured 0.538”.

The front sight for my Marlin® 39A was mounted to a

ramp. Barrel ramps

still use a 3/8” dovetail, but with a shorter length.

My Marlin® front sight measured 0.437”.

The thickness of the base measured 0.087”.

Since I was cutting the base from 0.125” thick

dovetail stock, the depth of the notch needed to be 0.038”.

The total height of the sight was 0.265” so the post

was 0.178” high.

I again

used CorelDraw® to design the front post, then exported the

pattern to my CAD/CAM program.

I used my hobby CNC mill to cut a channel in the base

for the post, and to cut out the base from the dovetail blank.

I also used the CNC mill to cut out the post from the

1/8-inch bar stock. I

silver-soldered the post into the channel I milled in the

base, then milled a 3/64 groove in the front ramp of the post.

I bead-blasted the new sight, cold-blued it as

previously described, then applied white appliance touch-up

paint to the groove.

The

dovetail base was just slightly larger than the dovetail in

the barrel ramp. I

used my 65-degree dovetail file to file one side of the sight

base until it fit. The

top of the base is higher than the top of the ramp, but the

base of the post sets on top of the ramp with no unsightly

gap.

Ruger®

Bisley Blackhawk®

My Ruger® Bisley Blackhawk® required a higher front sight.

Since the original front sight was 1/8“ thick, I

fabricated my own, higher front sight blade.

Instead of using steel and bluing the sight, I

fabricated it out of brass.

Refer to my article Fabricating

and Installing a Taller Front Sight for a Ruger® Bisley

Blackhawk®.

I again

used CorelDRAW® to design the pattern for my new front sight

blade. The height

was 0.495” but I designed it with an undercut front to

reduce glare, rather than a post or ramp.

I purchased

a piece of brass 1/8” x 3/4“ x 12” from OnlineMetals.com.

I decided to fabricate the new blade out of brass

because it’s easier to work with.

I realize that since brass is softer than steel the new

blade could get deformed easier, but I’ve had steel blades

get deformed by being knocked around, plus I can always make a

new one. I’m

really not that hard on my guns so the brass blade should be

just as durable as a steel one.

Plus, I don’t have to worry about finishing the

brass. However, I

could, if necessary, produce a blade made of steel using the

steel bar stock instead of brass.

I took the piece of brass, mounted it to a piece of

wood on my milling table, and milled out the new blade.

After I

milled the new blade I touched up the sharp edges with a

jeweler’s file and installed it in the front sight base.

I took a 1/16” drill bit and using the hole in the

sight base as a guide, drilled the roll pin hole in the new

blade. After I

drilled the hole I installed the roll pin.

Tactical

Solutions 1911 .22 Conversion Kit

I have a 1911 .22 Conversion Kit that I purchased many years

ago. This was the

same kit on which I installed a fixed ejector, refer to my

article Resurrecting

a 1911 .22 Conversion Unit.

This kit is currently manufactured by Tactical

Solutions which comes with an adjustable rear sight, but

my original kit had fixed sights.

In order to prevent the hammer from hitting the rear

sight I had to install a high profile Millett

adjustable sight which they no longer manufacture.

That meant I would also have to install a higher front

sight.

My

measurements for this new front sight were as follows:

Bar stock

thickness: 0.123”

Dovetail depth:

0.085”

Dovetail width:

0.330”

Dovetail length:

0.452”

Height of post:

0.360” as measured from the top of the slide to the

top of

the post.

Width of notch:

0.123”

Depth of notch:

0.123 – 0.085 = 0.038”

Final height of post: 0.085

+ 0.360 = 0.445”

I

followed the same procedure as I did for Jon’s rifle using

the above measurements to fabricate the base and post.

The above photo shows the installed taller front sight.

Summary

With the proper tools and materials I can now fabricate custom

front sights pretty much made to order.

I think the next time I fabricate a custom front sight,

I will mill the base so it is the proper thickness, then mill

a notch for the post. I

would mill a tab on the bottom of the post that would set in

the notch. I still

like the channel because it helps me to get the post soldered

straight. In fact,

if I made the notch deeper I could attach the post in the same

way some front sight posts are attached to a 1911 slide.

|