Fire

Lapping a Barrel

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Factory

rifled barrels are truly a wonder of modern manufacturing.

However, the manufacturing process often leaves the

bore rough. Pits

and burrs in the bore, although unseen by the naked eye, can

cause the barrel to foul after only a few shots, and can

affect accuracy.

There are

a number of ways to smooth the bore of a barrel:

- Shoot

the gun a lot – Although this method does work, it is

very inconsistent and does not always produce the

desired results.

- Hand

lap the barrel – This involves removing the barrel

from the receiver, producing a lead lap that fits the

bore, impregnating the lap with lapping compound, and

moving the impregnated lap through the bore.

- Polish

with a tight patch and fine abrasive compounds – It is

possible to polish a barrel using fine abrasive

compounds such as Remington Bore Cleaner or USP Bore

Paste. The

compound is applied to a tight fitting patch and run

back and forth through the bore.

This method works, but takes a very long time to

produce any positive results. (This method can be

accelerated with very positive results; see the addendum

at the end of this article.)

- Fire

lap the barrel – This is probably the easiest method

of all for polishing a bore.

Fire lapping involves imbedding different grits of lapping

compound into bullets and firing them down the barrel at a

very moderate velocity.

I use lead bullets for handguns, and copper-jacketed

bullets for rifles. The

fire lapping process accomplishes a number of positive

things:

- Smoothes

the barrel and removes pits and burrs

- Removes

tight spots

- Slightly

tapers the barrel from forcing cone to muzzle.

This taper keeps the bullet tightly sealed

against the lands and grooves as it travels down the

bore.

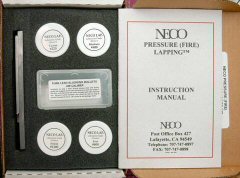

I purchased

a fire-lapping kit from NECO,

which included 4 grits of lapping compound, 220, 400, 800, and

1200. Their

instruction manual said to use lead bullets to fire-lap a

revolver barrel, and shoot multiple exact full cylinders of

bullets. (This is

so each chamber throat in the cylinder gets the same amount of

polishing.) They

recommended 12 rounds with 220 grit, 18 rounds with 400 grit,

and 24 rounds with 800 grit.

They did not recommend using the 1200 grit but they

stated it couldn’t hurt.

For rifle

barrels, they recommend firing five rounds of each grit,

cleaning the barrel, then slugging it to gauge the progress.

I prefer NECO’s other recommendation of shooting ten

rounds of each grit and cleaning the barrel after every five

rounds. It is

important to thoroughly clean a revolver barrel after every

full cylinder of shots, and to clean a rifle barrel after

every five shots to remove the powder residue and fouling.

Otherwise, I would be lapping the fouling and not the

barrel.

I spread a

thin layer of compound on the steel plate provided in the NECO

kit and rolled three bullets at a time between it and another

steel plate thereby impregnating the bullets.

I wiped off the excess compound from each bullet and

separated them by grit in preparation for loading.

A properly

impregnated bullet has a gray ring around the bearing surface.

This surface provides the lapping action as the bullet

travels down the bore. I

loaded each round with a light load of Red Dot, which produced

a low velocity load. I

normally destroy the cases after using them for fire lapping.

If I was to reload these cases, residual lapping

compound could contaminate the bullet, which would damage the

barrel. However,

because I plan to fire lap more then one gun of the same

caliber, I can re-use the cases, but I have to keep them

separated by grit.

Ok, off to

the range. As

mentioned before, I need to thoroughly clean the barrel after

every full cylinder for a revolver, and after every five shots

with a rifle.

So, what

about the results, and just how effective is fire lapping for

improving accuracy? First

of all, a fire lapped barrel is much easier to clean.

Because pits and burrs are removed, there is nothing to

hold fouling. In

most cases, a fire lapped barrel will come clean after only

two or three solvent-soaked patches.

I have a

Chinese Polytech M1A with which I could barely keep the shots

in a six-inch dinner plate at 100 yards.

I figured the barrel was rough built and could probably

be improved by fire lapping.

After fire lapping the barrel and cleaning up the

muzzle with a brass muzzle lap, I was consistently shooting

2-inch walnut husks at 100 yards.

On paper, I was printing sub minute-of-angle groups.

“Your results may vary”, as the disclaimers say,

but I was quite stunned by the results.

I would not

fire lap a custom-made barrel because those are usually

hand-lapped at the factory.

NECO recommends that the 220-grit lapping compound

should not be used in good quality factory barrels.

I did use the 220-grit on my Chinese M1A barrel because

I could see it was very rough inside.

I do not

fire lap every gun I own because most of them shoot great

right out of the box. However,

if I have a revolver that has a constriction in the barrel

where it is screwed into the frame, or a poor-quality barrel,

I will fire lap it. Fire

lapping will NOT restore a worn or shot-out barrel such as you

might find on a military surplus weapon, and it may not

improve the accuracy of an already accurate barrel, but it

will make the bore smoother and easier to clean.

Addendum

I found an interesting article online at the Twin City Rod

and Gun web site that provided a process for hand-lapping a

barrel using three different grits of cleaning compound and

tight patches. Fire-lapping involves shooting a bullet

impregnated with lapping compound down the bore at a much

reduced velocity and pressure. This has the effect of both

polishing and tapering the bore for maximum accuracy, but it

can also open and lengthen the throat. I found an article on

the Los Angeles Silhouette Club web site written by Ken

Mollohan that has a little different method for fire-lapping.

Ken first ran a bore mop impregnated with J-B® Bore Cleaning

Compound through the bore being careful not to get any

compound in the chamber, then fired a low velocity, low

pressure jacketed round through the bore. He repeated this

process 5 or 6 times, then thoroughly cleaned the barrel. This

process not only provided all the benefits of fire-lapping,

but it prevented damage to the throat, and since the bullet

itself was not impregnated with the lapping compound, the

cartridge cases did not have to be thrown away.

I decided to try a

combination of both methods on a new M1 Garand barrel. First I

loaded 10 rounds of .30-06 with 5.0 grains of Red Dot behind a

150 grain FMJ boat tail .308 bullet and a large rifle magnum

primer. I put an empty case in the chamber and closed the bolt

to prevent compound from getting into the chamber, impregnated

a bore mop with USP Bore

Paste, then ran the mop back and

forth through the entire length of the bore 20 times. This

left a small amount of compound in the bore. I fired one low

velocity round through the barrel, inserted the same empty

case into the chamber that I had used before, then again ran

the impregnated bore mop back and forth through the bore

several times. This cleaned any powder residue and fouling

from the bore and prepared it for a second shot. After

performing this for 5 shots, I thoroughly cleaned the barrel

using solvent and dry patches.

I threw away the first empty

case I used and put a new empty case in the chamber and closed

the bolt. I impregnated a clean bore mop with J-B® Bore

Bright which has a finer grit and ran the mop back and forth

through the entire length of the bore 20 times. I fired one

low velocity round through the barrel, inserted the same empty

case into the chamber, then again ran the impregnated bore mop

back and forth through the bore several times. This again

cleaned any powder residue and fouling from the bore and

prepared it for a second shot. After performing this for 5

shots, I thoroughly cleaned the barrel using solvent and dry

patches. The bore was mirror bright and smooth and was now

ready for full pressure loads, and in theory the new throat

was polished which should help to prevent excessive fouling.

The advantages of using this

method are that the chamber throat is not excessively

lengthened due to using rougher grit, and the cartridge cases

can be reused for normal loads. As for the results, I

fired maybe 60 rounds through the new barrel and it cleaned up

with only three patches and I had no copper fouling. Now

that's success!

|