Customizing a Kimber Pro Carry HD II

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Click on any blue text to go to

a product/seller web site.

Introduction

I received a very nice bonus at the end of 2015 so of course

I bought a new gun! When I was in high school I was a

member of the school rifle team. Our faculty advisor owned

a Colt 1911 in .38 Super and allowed us to shoot it if we

bought the ammo. That was the first handgun I ever fired

and I have wanted to add a .38 Super to my collection.

I have a

number of full-size 1911’s in my collection in .45 ACP, 9mm,

and .22 LR, but I wanted one in stainless steel, .38 Super,

and Commander length. To build one from parts would have

cost me about $1,500 and over 60 hours in labor so I started

to search the Internet to see if I could find a commercially

made model that fit my specifications. I finally found and

purchased a Kimber Pro Carry HD II.

Kimber

Pro Carry HD II

Kimber has developed an excellent reputation in the 1911

market and has many models to choose from. The Pro Carry

series of pistols have a 4-inch bushingless barrel which

makes them 1/4-inch shorter than a standard Commander-length

pistol. The barrel is flared at the end so the barrel

opening in the slide is wedged against the flare when the

slide is in battery.

The

series II has a firing pin block that is released by the

grip safety rather than by the trigger bow as in a Colt

Series 80 so it does not affect the trigger pull. Many

shooters with series 80 guns remove the firing pin block

because of how it affects the trigger, but I will keep mine

in place.

My

research indicated that the HD may stand for “heavy duty”

because the frame is all steel instead of aluminum alloy,

and in fact mine is all stainless steel with a nice matte

finish. The gun came with molded rubber grips which seemed

to enhance my grip on the gun, fixed Novak-style sights, and

one magazine that holds 9 rounds. This production pistol

was tight; there was no slide rattle on the frame, and the

bushingless barrel locked up to the slide perfectly which

enhances accuracy.

Because

the gun has a full-length recoil spring guide rod, to

disassemble the gun I had to lock the slide open, insert the

L-shaped takedown tool into the hole in the guide rod, then

release the slide. The tool keeps the recoil spring

compressed so I can remove the parts from the slide. I see

this as being problematic in the field since I may not have

that tool available.

My only

dislikes were the fixed sight, the need for the takedown

tool, the trigger shoe was too long for my hand, and the

trigger had just a bit of creep. Other than those minor

squawks, this gun was ready to go right out of the box.

Because the firing pin block is connected to the grip safety

I had to be sure I kept my hand off of that safety when

removing or installing the slide onto the frame, otherwise

the push rod would interfere with the travel of the slide.

Customization Plan

Although this gun was ready to go right out of the box, I

wanted to make a few modifications of my own. Most of these

modifications wouldn’t really improve the gun but just my

personal preferences. My modifications would be to:

-

Increase the secondary angle on the sear to remove the

creep

-

Replace the trigger with a medium-length trigger

-

Adjust the trigger for pre-travel and over travel

-

Checker the front strap

-

Install a bobtail mainspring housing

-

Checker the bobtail mainspring housing

Because

I’m going to take a file to my new gun this will probably

void Kimber’s excellent warranty. However, this really

doesn’t bother me since I can replace/repair most problems I

encounter with a 1911 pattern pistol.

Removing

Creep

The

trigger pull on this gun really wasn’t bad; it broke cleanly

at 5 pounds but had just a little bit of creep. When I

examined the sear it looked like it had a very small

secondary angle; the width of this angle should be 0.020”.

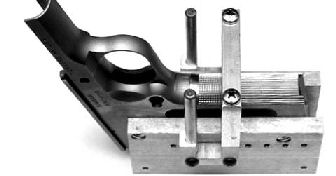

I installed the sear into my Marvel 1911 Sear/Hammer Jig

#080-823-000 and following the instructions that came

with the jig, used a medium-fine ceramic stick

#080-721-604 to increase the angle. The trigger is now

nice and crisp with no creep and breaks at exactly 3-pounds.

Replacing

the Trigger with a Medium-Length Trigger

My hands are not very large so I don’t like having to

stretch to get the first pad of my trigger finger on a long

trigger. Fortunately,

Nighthawk Custom sells short, medium, and long length

adjustable triggers. I purchased a medium-length adjustable

trigger

#333149 from

MidwayUSA.

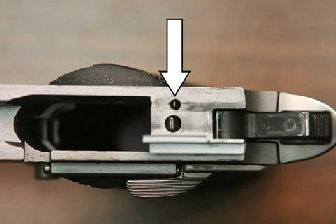

This was

not quite a drop-in part; it required some fitting. To get

the trigger shoe to fit in the frame I had to polish the top

and bottom as shown by the white arrows in the above photo.

I only had to rub the top and bottom faces across 400-grit

wet/dry sand paper about 20 times to get the trigger to fit

and move smoothly with no up or down movement. This results

in a consistent trigger pull.

Adjusting

Pre-Travel and Over Travel

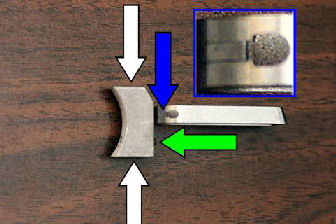

The trigger came with pre-travel adjustment tabs as shown by

the blue arrow and enlarged inset in the above photo. There

was one tab on each side of the trigger bow. To adjust

pre-travel, I bent the two tabs out just a bit and

reassembled the gun. With the hammer in the half-cock or

safety notch position the trigger should not move. If the

tabs are bent too far out the grip safety will no longer

function.

The

trigger came with an over travel adjustment set screw shown

by the green arrow in the above photo. I installed the set

screw into the trigger with Loctite blue. To adjust over

travel, I turned in the screw until the safety notch on the

hammer just touched the sear when it fell, then backed the

screw off 1/8 turn. This was a trial and error process; the

steps are as follows:

-

Cock

the hammer.

-

Turn

in the over travel adjustment screw 1/4 turn.

-

Hold

the hammer with two fingers, pull the trigger, and allow

the hammer to gently fall.

-

Repeat steps 2 and 3 until the safety notch on the

hammer just touches the sear when the hammer falls.

-

Back

off the adjustment screw until the safety notch no

longer touches the tip of the sear when the hammer

falls; over travel is now adjusted properly.

Checkering the Front Strap

I like the positive grip that a checkered front strap

provides. I purchased a 20 lines-per-inch checkering file

#080-310-401 and the Marvel Precision 1911 Auto EZ

Checkering Fixture

#588-100-011. The checkering fixture is an expensive

tool, but ensures I get nice straight lines.

I

completely stripped the frame and installed the fixture onto

the grip screw bushings. Following the included

instructions, I set up the fixture to make the relief cut in

the frame. The relief cut serves as the border for the

checkering and allows me to take full strokes with the

checkering file.

I used

the 3/16 file that came in the Kart Precision Barrel XAct

Fit Tool Kit

#472-015-000 to file the border about 0.030” deep. I

could have used a flat jeweler’s file instead of the Kart

file. This left a sharp edge at the top of the border

underneath the trigger guard which I will file/grind smooth

after I finish the checkering.

I reset

the fixture to make the vertical cuts. I installed a

plastic tie wrap in the border to prevent the file from

moving too far, and covered the exposed trigger guard with

three layers of masking tape. This prevented me from

scratching the frame in case my file slipped. I rotated the

jig around the circumference of the front strap and cut the

vertical lines. I cut until the file skidded along the

metal and wouldn’t cut anymore. This process takes hours to

complete and should not be rushed. “Patience is a virtue”

as they say.

Notice in

the above photo how I scratched the front strap of the frame

under the trigger guard. I had to remove the cable tie to

get nice, even lines. These scratches will be removed when

I blend and polish the sharp edge of the border.

After the

filing was completed I used a small, triangular file to

clean up each line. I was careful not to allow the file to

skip across a line.

I set up

the fixture to make the horizontal cuts and cut down the

length of the front strap. I again cut until the file would

not cut any more. As I moved the fixture down the frame I

was sure to keep the file lined up with the prior cuts.

After

cutting the horizontal lines I again cleaned them up with a

small triangular file. I coated the checkering with a blue

marker and went over all the horizontal and vertical lines

once more to ensure they were all even.

I used my

6-inch narrow pillar file

#191-400-760 and filed a border on the bottom of the

frame. I wrapped some 400-grit wet/dry sand paper around

the file and polished the border until it was smooth and all

filing marks were removed.

I then

used my Dremel tool and a fine sanding drum to smooth the

top ledge of the border under the trigger guard, then used

400-grit wet/dry sand paper and “shoe shined” under the

trigger guard to remove and smooth out the grinding and

filing marks.

Finally,

I put the frame in my bead blaster and blasted it with

glass-bead media to get the same matte finish as the

factory. This process also dulls the sharp points of the

checkering just a bit so they don’t dig into my hand so

much.

Checkering the Bobtail Mainspring Housing

To make

this gun more carry friendly I wanted to round the bottom

rear corner of the mainspring housing and frame. I had

never performed this process before and wanted to add it to

my skill set. I purchased an Ed Brown smooth, stainless

steel bobtail mainspring housing

#168206 and installation fixture

#259442 from MidwayUSA. The smooth housing came with

all the internal parts, and was $25.00 cheaper than the

checkered version.

I wanted

the new housing to be checkered like the front strap of the

frame. It was cheaper to do the checkering myself than pay

for a factory checkered one. I installed the mainspring

housing in my vise and used the bronze jaws as a guide to

file the lines. I cut the first set of lines using my 20

LPI checkering file with the housing deep in the jaws as

seen in the photo above. After the first set of lines were

cut I positioned the mainspring housing above the jaws and

finished the vertical lines. The first set of lines acted

as a guide for the rest of the vertical lines.

I

repositioned the mainspring housing deep in the jaws so I

could again use the jaws as a guide to file the first set of

horizontal lines. I then moved the file over 5 lines to cut

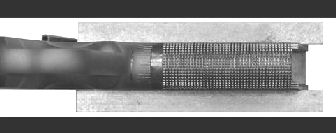

the next set of lines. You can see the result in the above

photos.

Installing the Bobtail Mainspring Housing

There are a couple of videos on

YouTube showing how to install the bobtail mainspring

housing. Installation requires drilling a new mainspring

housing retaining pin hole and reshaping the frame and

grips. The instructions say to install the fixture into a

vise, center a 5/32” drill bit in the top hole (this will be

the location of the new retaining pin hole), insert the

frame onto the fixture, lock it place with the retaining pin

in the bottom hole, then drill the new hole. The hole

should be started with a center drill, then completed with

the 5/32 drill bit. The center drill has a thick shaft

which prevents the bit from wobbling and wandering when

drilling the smaller pilot hole. If not done properly the

drill bit will wobble and/or wander and the hole will be

off-center or oval in shape. One of the YouTube videos I

watched showed how the user ovaled the hole because he

allowed the bit to wobble, then he had to weld up the frame

to correct his mistake.

I don’t

have a center drill, although they are available on ebay at

fairly inexpensive prices. Without a center drill, there

are a few methods I can use to prevent the bit wobble

problem:

-

Install the drill bit deep into my chuck to prevent it

from wobbling. The shorter the length of the bit, the

less chance for the bit wobble and wanter.

-

Plunge-mill the hole with a 5/32” square end milling

bit. I would only be able to mill one side, then use a

5/32” drill bit to finish the other side. The fixture

would act as a drill guide for drilling through to the

other side of the frame. This is the method I

ultimately used.

-

Install the fixture on the outside of the frame to use

as a drill guide for the first hole. One YouTube video

showed this method, but I would be concerned about not

getting it aligned properly and being able to hold the

jig in place.

I

installed the fixture horizontally in my machinist’s vise

and leveled it with a parallel. Because the fixture was not

in the center of the vise jaws I had to tighten the vise

very hard to prevent the fixture from moving. Yup, I

learned this the hard way when the fixture rotated under the

pressure of milling the first hole, and I had to stop and

set everything up all over again! Fortunately it didn’t

mess up the hole.

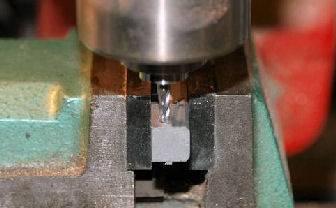

I

installed a 5/32 square end milling bit and centered it in

the top hole. This was a carbide, center-cutting bit so I

could plunge mill the hole.

I

installed the frame onto the fixture and held it in place

with the hammer pin. The hammer pin is the same diameter as

the mainspring housing retaining pin, but the hammer pin has

a lip that prevents it from falling through the hole.

I

plunge-milled the first hole with the 5/32 square end bit.

I used very light pressure on the mill because I wanted the

bit to cut and not bind or wander. The bit cut through the

frame as if it were butter.

After the

hole was milled I removed all the internal parts from the

new bobtail mainspring housing and installed it in the frame

to ensure the new hole in the frame would line up properly.

I had to ream the new hole with a #21 drill bit to get the

pin to fit, but it was lined up properly.

I

reinstalled the frame onto the fixture and locked it in

place with the hammer pin as before. I centered a #21 drill

bit in the top hole and drilled completely through the

frame. The fixture acted as a guide so the drill bit

wouldn’t wobble. The mainspring housing retaining pin fit

perfectly through the new holes in the frame and in the

bobtail mainspring housing.

The

inside of the frame that I planned to cut off I painted with

a blue marker. I reinstalled the internal parts into the

mainspring housing and installed the housing onto the frame

with the retaining pin. I took a sharp scribe and scribed

around the mainspring housing. This mark, which you can see

in the above photo, told me where to stop cutting the frame.

I used my

Dremel tool and a cutoff wheel to cut the corners. I

installed the mainspring housing in the frame and installed

the retaining pin. I used my Dremel tool with a fine

sanding drum to shape and contour the sides to the bottom of

the mainspring housing. I didn’t mind grinding into the

housing since I was going to finial polish the frame and

housing anyway.

Once this

was done I used strips of 400-grit wet/dry sand paper and

“shoe shined” the back of the mainspring housing and edges

of the frame until they were smooth and no grinding marks or

divots were present. I then bead-blasted the polished metal

to match the rest of the finish on the frame.

If you

look at the above photo you can just barely see two small

divots at the bottom of the frame where it meets the new

mainspring housing. These were what was left of the

original retaining pin holes. The original holes were a bit

farther in from the rear edge of this particular frame which

left the two divots. I don’t know if this is the same for

all Kimber frames, or just my frame. On a standard 1911

frame these small divots would not exist after blending the

frame to the bobtail mainspring housing because the holes

would be closer to the rear edge of the frame.

I trimmed

the rubber grips to allow for the cut in the frame and the

new location of the mainspring housing retaining pin. The

above photo shows the results. The grip feels a bit strange

in my hand because it is shorter, but this doesn’t seem to

affect the handling characteristics. The gun is very

comfortable to carry, because there is no corner to stick

into my side. Overall I am pleased with the modifications I

made to my Kimber Pro Carry HD II, but again, I have

probably voided any warranty that came with the gun.

Failure

to Feed

I put together some dummy rounds so I could test the

function of the pistol. To my surprise I got a failure to

feed. After successfully feeding a round 3 or 4 times, that

same round got jammed under the extractor and would not

allow the slide to go into battery.

When I

examined the cartridge I found it had sharp grooves cut into

the rim of the case. These grooves were catching on the

extractor hook which prevented the round from feeding. I

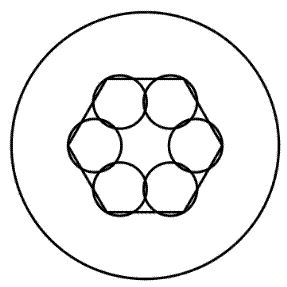

discovered this was caused by the sharp edges on the feed

lips of the Kimber magazine as shown in the above photo.

I pushed

the follower down into the magazine with a pencil and held

it in place with a pin pushed through one of the holes in

the side of the magazine body. I took a narrow 220-grit

stone and stoned off the sharp edge. I then took my Dremel

tool with a Cratex bit to finish rounding and smoothing the

edges. Prior to doing this I couldn’t remove the first 3

rounds from the magazine with my hand. Now the cartridges

slip easily out of the magazine. I purchased a second .38

Super magazine manufactured by Mec-Gar and found their feed

lips were already rounded and smoothed.

Addendum 04/08/2020 Corona Virus Shelter In Place Project

Replacing the Front Sight

I purchased a Hi Viz #KB2015 fiber-optic front sight from

Amazon.com to replace the blue steel sight.

I am a big fan of light-pipe sights because they are

easier to see against a dark background.

I used a brass punch and “removed the sight from left

to right”. I

removed the light pipe and installed the sight onto the slide

from right to left.

The new sight fit perfectly.

The sight came with 3 light pipes:

solid white, optic red,

and optic green. I

installed the green light pipe which I prefer.

Replacing the One-Piece Full-Length Guide Rod (FLGR)

I have been viewing with interest a series of YouTube videos

by 18echosf (Adrian) on how he replaced the FLGR on his Kimber

Pro Carry II with a commander-length guide rod.

In his first video he explained he was doing this was

because he didn’t like having to use the Kimber L-tool to take

down the gun when in the field.

https://www.youtube.com/watch?v=ZSne_GWjB4Y

By the way, a bent

paper clip will work in place of the L-tool, but again, who

carries the tool or paper clips to the range where they can

get lost?

Eventually Adrian decided to go back to the Kimber full-length

guide rod because he found the Wilson and Colt

commander-length guide rods were peening the inside of his

frame.

https://www.youtube.com/watch?v=RUotr1VgcPU&t=21s

He discovered that the head of the short recoil guide

was narrower than the Kimber and was causing the peening.

Personally, I think he’s going to get the peening

regardless of what spring guide he uses because he has the Pro

Carry II model which has an aluminum frame.

I have the Pro Carry HD II model which has an all-steel

frame, so I don’t think I should get this peening problem.

Disassembling the Kimber Recoil Spring and Guide Rod Assembly

I decided to install a two-piece full length guide rod.

I used the original Kimber recoil spring and reverse

plug, but I first had to disassemble the Kimber recoil spring

and guide rod assembly.

Hobbygarage619 sells a set of tools on ebay for disassembling

the Kimber.

https://www.ebay.com/p/1046107556?iid=202476500431#viTabs_0

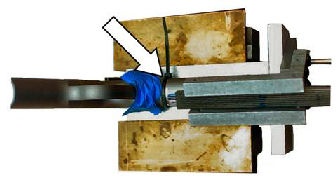

I made a disassembly tool by cutting a piece of 1/4” aluminum

and drilling a 15/32” hole in the middle.

Ok, so I can’t cut a straight line with a hack saw;

this is not a precision tool!

The hole was not quite wide enough to slip over the reverse

spring plug, so I took a Dremel tool with a 3/8” sanding disk

and opened the hole until it would just fit.

I placed the tool over the spring plug as show in the

above photo, placed the wide rear of the guide rod in the heel

of my hand, placed the fingers of that hand over the tool and

pressed down until I could remove the L-tool, then carefully

released the spring tension.

The other method is to install the assembly in the slide,

press against the head of the recoil rod with your thumb until

tension is released from the L-tool, remove the L-tool, then

carefully release the spring tension.

Putting it back together with your thumb can be a

painful process, which is why I like to use the tool instead.

In my stock of 1911 parts I had a Wilson 2-piece full-length

guide rod assembly that I had purchased from MidwayUSA.com

part

#136387. This

part was made for a full-length 1911 so it was a bit long for

my Kimber.

I marked the front of the guide rod and used my lathe to cut

off the excess. I

faced off the front and slightly chamfered the edge.

The Wilson two-piece full length guide rod (FLGR) had a

hex hole in front so it could be unscrewed with a hex key.

When I shortened the front, I removed the hole.

If I had been smart, I would have cut a slot so I could

use a screwdriver to unscrew the front, but no, I wanted to

get fancy!

I used CorelDRAW 12 to design a milling pattern, then exported

it to BobCAD-CAM v20 to create the G-code for my table-top CNC

mill. I used a

1/6” square end bit to mill the six holes, then used a 1/8”

square end bit to mill out the center.

Because of the shape of the hole I now needed to use a T27

Torx bit to unscrew the rod for disassembly.

I think I’ve gone from the frying pan into the fire!

In my range bag I carry a small screwdriver kit I

purchased from Walmart that has Torx bits in it, so I should

be ok in the field.

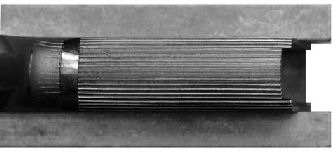

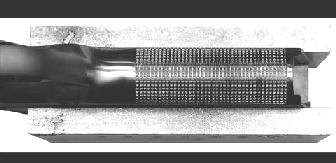

I installed the spring onto the rear half of the guide rod,

installed the reverse spring plug in the slide, and installed

the spring/guide rod into the slide.

Notice how the spring is bowed in the above photo.

When installing the slide onto the frame I must hold

the spring against the slide to prevent it from binding.

With the slide installed in the frame I locked the slide open

with the slide lock.

I put a drop of Loctite blue on the threads and screwed

the front part of the guide rod onto the rear part.

To disassemble the gun for cleaning I first need to

unscrew the front part of the guide rod, then I can remove the

slide from the frame.

The debate on forums over short guide rods vs. one-piece

FLGR’s vs. 2-piece FLGR’s continues ad-nauseum.

Some 1911 shooters don’t like the 2-piece FLGR because

they sometimes come apart during heavy use.

The Loctite blue should take care of this problem but

will still allow me to disassemble the gun for cleaning.

In 2005 I took an online 1911 build course from the late Dave

Sample. He was a

proponent of the full-length guide rod.

I have built two additional 1911’s all with FLGR’s

based on what I learned in Dave’s class.

If they were good enough for Dave, they’re good enough

for me.

|