Cleaning Up a 1947

Marlin® 39A – Part II

by Roy

Seifert

Click here to purchase a CD with this and

all Kitchen Table Gunsmith Articles.

Disclaimer: This

article is for entertainment only and is not to be used in lieu of a

qualified gunsmith. Please

defer all firearms work to a qualified gunsmith.

Any loads mentioned in this article are my loads for my

guns and have been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of these loads,

or use or misuse of this article.

Please note that I am not a

professional gunsmith, just a shooting enthusiast and hobbyist, as well

as a tinkerer. This

article explains work that I performed to my guns without the

assistance of a qualified gunsmith.

Some procedures described in this

article require special tools and cannot/should not be performed

without them.

Warning: Disassembling

and tinkering with your firearm may void the warranty.

I claim no responsibility for use

or misuse of this article. Again,

this article is for entertainment purposes only!

Tools

and firearms are the trademark/service mark or registered trademark of

their respective manufacturers. Click on any

blue text to go to a

product/seller web site.

Introduction

Wow, it’s been 10 years since I purchased this rifle.

It’s a great shooter; very accurate and

the action is butter smooth. I took

it out of the gun safe to give it a quick going over and decided to make a few

more improvements. I wanted to keep

it as close to the 1947 pattern as possible, but I did make a few changes.

Re-Bluing the Receiver

As mentioned in my previous article, this rifle did have some surface rust

mostly on the right side of the receiver.

I tried to polish out the rust and cold blue it, but the cold blue

solution combined with the original bluing created more rust!

I was finally able to make it look somewhat decent, but it didn’t come

out perfect. Over time that cold

blue job started to rust, so I decided to do it over.

I

completely disassembled the right receiver half.

This half had all the action parts except the bolt.

Then I removed the bad cold blue with 400-grit wet/dry sandpaper and

polished with a buffing wheel and 400-grit polish.

I

degreased the receiver with acetone, then heated it with a heat gun.

I used a large cotton dauber to apply Brownell’s Oxpho-Blue liquid.

I dipped the dauber into the solution and applied it liberally on the

steel for 60-seconds. I then wiped

off the excess liquid and polished the metal with 000 steel wool.

I repeated the process using a new dauber.

At first the bluing was splotchy, but eventually it came out even after

10 applications. After the final

polish with steel wool, I applied some Minwax finishing wax to protect the newly

blued surface.

If the

bluing doesn’t hold up, I’m going to try the process found on YouTube by

Ginsboy2003: https://www.youtube.com/watch?v=X-CDOJF-TmY

Following his process, I would remove the old bluing, apply Mark Lee

Express Brown #2, then apply the Oxpho-Blue.

The browning provides durability, and the cold blue provides the color.

Changing the Rear Sight

I

really didn’t like the Marble’s leaf sight, so I replaced it with a Marlin

folding leaf sight I had from my 336.

I drifted out the Marble’s sight and installed the Marlin sight.

I adjusted the Marlin sight so when I looked through the peep it was

aligned with the front sight.

Adding

Sling Swivels

In my

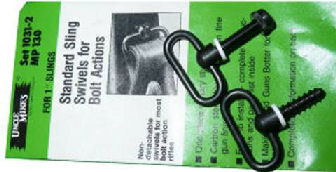

box of sling swivels, I found an old set of Uncle Mikes fixed 1-inch sling

swivels. The later versions of the

39A came with fixed sling swivels.

This package came with two swivels; one with a wood screw to install into the

butt stock, and one with a 10-32 machine screw for the fore end cap.

I

carefully marked the center bottom of the fore end cap and milled a 0.159” hole,

then tapped the hole with a 10-32 tap.

The machine screw swivel was not threaded all the way to the stud, so I

took a 10-32 die and ran it backwards over the threads to cut threads up against

the stud. I trimmed the excess

threads with a Dremel cutoff wheel and installed the swivel with the white

spacer. The spacer ensured I

installed the swivel perpendicular to the barrel. I used a fine sanding drum on

my Dremel tool to grind the end of the shaft flush with the inside of the end

cap.

I

removed the swivel from the end cap, cleaned the threads of the stud and end cap

with acetone, applied some JB Weld epoxy to the threads, then reinstalled the

swivel. I allowed the epoxy to cure

for 24 hours, then reassembled the rifle.

For

the rear sling swivel, I placed some painter’s tape on the bottom edge of the

butt stock so the center of the tape was 1 1/2-inches below the Marlin bull’s

eye. The tape helped to prevent the

wood from splintering. I used a

center-punch to mark where to drill in the stock and used the smaller swivel

base drill bit to drill into the stock.

I

installed the white spacer, applied some grease to the threads and screwed the

swivel into the stock. My rifle now

has sling swivels that look factory.

Making

a Sling

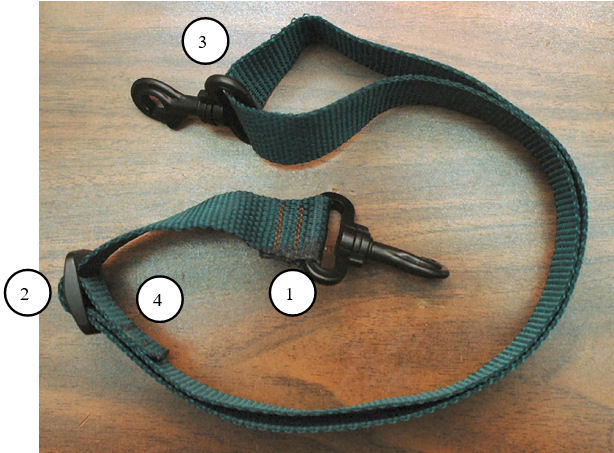

I made

my own sling using webbing and plastic hardware I had on hand.

I cut 44” of 1 1/2” green nylon webbing to make the sling.

I use a lighter to seal the ends to prevent them from fraying.

In the

above photo I tried to show how I assembled the sling.

-

I fed one end of the

webbing through a swivel hook and stitched it.

This hook is attached to the stock sling swivel.

If you don’t have access to a sewing machine strong enough to stitch

webbing, you can use a tri-glide to hold the end.

Strapworks has a video showing how to do this:

https://www.youtube.com/watch?v=3xB86Lm7vBw

-

I fed the other end of

the webbing through a tri-glide.

-

Then fed the end through

another swivel hook. This hook is

attached to the fore end cap sling swivel.

-

I fed the end through

the center-bar of the tri-glide and stitched it in place.

I move

the tri-glide up or down on the strap to adjust the length of the sling.

When stored in my gun safe, the tri-glide is at the bottom of the sling

keeping the sling “dressed” so it doesn’t drag on the floor or get tangled with

other rifles. To carry the rifle, I

move the tri-glide up the webbing until the sling is at the desired length.

In my

prior article, I replaced the Lyman tang peep sight with a Marbles tang peep

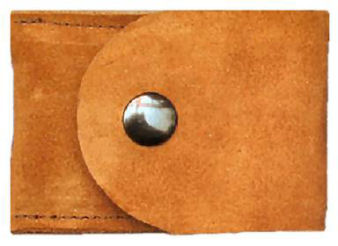

sight. I made a small pouch out of

chap leather to carry the extra apertures that came with the sight.

The pouch fits on the sling so I always have those apertures handy and

don’t lose them. I keep them in a

small plastic bag so they won’t rust being next to the leather.

The pouch is large enough that I can carry extra parts or small tools.

Replacing the Front Sight Base, Front Sight, and Adding a Hood

I

decided to replace the white-line front sight with a green fiber-optic sight.

I’m a big fan of fiber optic sights and green seems to work best for me.

I purchased a front sight and open front sight hood from ebay.

The front sight was designed specifically for the 39A, and the open hood

allows light to illuminate the green fiber optic.

The

bottom of the hood has a lip that fits into a corresponding groove on one side

of the hood channel. My 39A front

sight base did not have that groove; I’m sure this was a later factory

enhancement. I replaced the front

sight base with the base I removed from my Marlin 336 when I converted it into a

takedown rifle. (Refer to my article

Building a Backpacker

“Scout” Rifle.) Apparently

on earlier large caliber rifles the hood would shift and eventually come off

during recoil, so Marlin added the lip.

The front sight base fit perfectly on my 39A barrel.

I used

a 65-degree dovetail file

#080-648-165 I purchased from Brownell’s to remove a small amount of metal

from the sight dovetail until it fit into the base.

I filed the sight, NOT the base.

This was a trial and error process.

After 3-5 strokes with the file I tested the sight for fit.

When the sight just started to fit in the dovetail, I used a brass punch

to finish drifting it in place.

This

rifle was already sighted-in for 50-yards.

The fiber-optic front sight is lower than the sight I made, which will

change the impact of the bullet. I

used my Bushnell Universal Laser Boresighter I purchased from MidwayUSA.com

#636671 to

see where the existing sights were adjusted in relation to the red laser dot.

After I installed the new front sight, I adjusted the peep and blade

sights to the same position in relation to the red dot.

The

Bushnell boresighter fits in the end of the muzzle and comes with expandable

arbors to fit bores from .22 through .50.

I don’t like the in-chamber boresighters because I’ve had problems in the

past with the laser reflecting off the bore and causing interference which makes

the dot difficult to see.

Adding

a New Butt Pad

In

spite of my efforts to repair the plastic butt plate, it still broke, so I

decided to add a rubber butt pad. I

purchased a Marlin butt pad from MidwayUSA

#680699

which required some minor fitting.

You can see in the above photo I didn’t get the angle of the toe exactly

correct, but it still looks good.

In the

above photo you can see what the rifle looks like with all improvements

installed. The sight hood and sling

swivels make the rifle look factory, and the green fiber-optic front sight and

sling add to the utility of the rifle.

I am very pleased how my rifle came out.

Carrying Spare Ammo

For

the range I bring along my Spee-D-15 loader I purchased from MidwayUSA.com

#511932.

This loader has 8 tubes arranged around a

central axis giving me 120-rounds. I

remove the inner magazine tube from the rifle, rotate the spout on the loader to

align with one of its tubes, and with the muzzle pointed away from me, place the

spout at the end of the magazine tube, tip up the loader, and 15 rounds slide

down into the tube. If I want to

fill the magazine tube to full capacity, I can top it off from a box.

The Spee-D loader is

much too bulky to carry in the field, although FortuneCookie45LC has a video

showing how he carries his in the field

https://www.youtube.com/watch?v=P-W6FiBrV3I. For

field use I carry two Marble Arms Catch .22 ammo carriers.

Each carrier holds 50-rounds in ten 5-round pockets.

The top slides open to expose one pocket at a time.

Each carrier comes with a molded-in belt clip so I have 100-rounds at the

ready. To load the rifle, I pour from the

Catch .22 pocket directly into the magazine tube.

|