Ruger® Mini-14® Cycling Problems

by Roy Seifert and Bob Shrank

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

A reader of the Kitchen Table Gunsmith, Bob Shrank, recently

sent me an email describing a problem he was having with his

stainless steel Ruger® Mini-14®:

“Dear

Kitchen Table Gunsmith,

I

enjoyed your article on using foreign ammo in your .223 Ruger

Mini 14. [Refer

to my article Fixing

the Ruger® Mini 14/30 Bolt to Shoot Imported Ammunition.]

I have two of

them and enjoy shooting them.

After purchasing a new [stainless steel] model last year, and shooting it a bunch of times running several 100

round full [magazines]

through it, I decided to give it a thorough cleaning.

Without any written instructions, I ended up taking off

the gas port block to remove the forearm.

Even though I marked the barrel with a marker, and

carefully repositioned the block.

My almost new [stainless steel] Mini

14 is now a single shot, or worse, it jams all the time.

Is there a simple fix for this?

I

have considered taking my other Mini 14 apart to see if I can

match the amount of gas hole exposed, but I’d like to

prevent another problem. Can

you please help me out?”

It had been

awhile since I worked on a Mini-14 or Mini-30 but I remembered

there was some type of alignment pin involved with the gas

block so I got out my NRA firearms assembly book and looked up

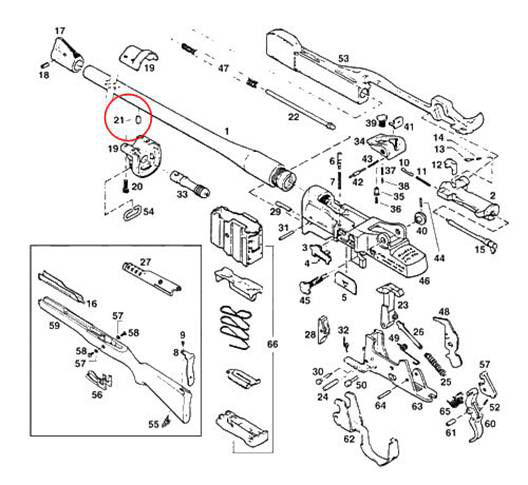

the Mini-14. Part

#21 circled in red in the above figure was listed as the gas

port bushing.

Gas

Port

Bushing

(not actual size)

The gas

port bushing has two functions; it properly aligns the gas

block with the barrel and piston, and it directs the hot gas

to the piston. Without

that bushing there would not be enough gas funneled to the gas

piston causing the symptoms Bob described.

I replied to Bob’s email with my suspicion that he

probably lost the gas port bushing when disassembling his

rifle. His reply

to me was that he did remember hearing something hit his

basement floor as he removed the gas block.

No

reflection on Bob here because I give him kudos for working on

his own rifle, but before disassembling a firearm beyond what

the manufacturer recommends for normal cleaning and

maintenance (removing the gas block is not recommended by

Ruger for normal cleaning and maintenance) it’s always good

to have an exploded diagram on hand.

This has saved my bacon a number of times with my own

guns. I recommend

the NRA

Firearms Assembly books which I have in my library

available direct from the NRA.

You can also find them on ebay of all places.

I also have The Gun Digest Book of Exploded Firearms

Drawings, 2nd Edition which has many diagrams of

older firearms no longer in production.

This book is out of print, but you can sometimes find

copies on ebay. Numrich,

also known as Gun Parts

Corp, has many schematics of older, obsolete firearms.

Another

gunsmithing trick is to disassemble a firearm over or inside a

box to catch small parts or flying springs.

Even placing separate cloths over and under the

assembly you are working on will prevent the loss of flying

springs or small parts. There

is almost no worse feeling in the world than having a spring

fly off into a crowded basement or work room, or having a

small part drop out of sight.

I believe these parts go to the same place as odd

socks.

I told Bob

that he could order the gas block bushing direct from Ruger,

from Numrich, or other parts suppliers on the internet such as

MidwayUSA or Brownells

and his rifle would be back in working order in no time.

(Photo

courtesy Bob Shrank)

You can see

from Bob’s photo above just how dirty the gas block got.

The arrow points to the gas block bushing which he did

not lose after all. After

he cleaned the gas block and associated parts he reassembled

the rifle but did not get the gas block screws tight enough so

gas was leaking causing the malfunctions.

Perhaps this occurred because the bushing was not

properly aligned with the barrel and piston.

Regardless of the reason, gas was leaking preventing

the rifle from cycling. When

he disassembled the gas block once again he could see where

the gas was leaking which required him to do another thorough

cleaning.

(Photo

courtesy Bob Shrank)

After all

the parts were cleaned he reassembled the rifle making sure

the gas block bushing was aligned and in the hole in the gas

piston (#33 in the exploded diagram) and all the gas block

screws were tight. A

quick trip to the range confirmed that he had his rifle back

in working condition.

Sometimes

the most difficult part of maintaining a firearm is getting it

back together after having taken it apart.

However, Bob should get some satisfaction out of being

able to diagnose and fix a problem himself.

That’s what gunsmiths do, both hobby and

professional, diagnose and fix problems.

Great job Bob!

|