Polishing

Revolver Cylinder Chambers

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

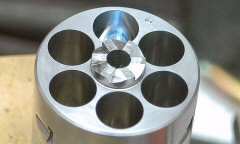

When a

revolver comes from the factory, the chambers in the

cylinder are often just rough-cut and can contain burrs and

cutting marks. These

burrs and cutting marks can make it difficult to extract

empty cases, and difficult to remove powder fouling.

Polishing the chambers makes the cases easy to

extract, and makes the chambers easy to clean.

The

processing for polishing chambers is relatively easy and

only requires simple power tools:

- Use

a special medium-grit hone to hone/polish each chamber

to remove tooling marks

- Final

polish using a fine-grit hone

It is

difficult to tell from my photos, but each chamber had

tooling marks around the circumference down the entire

length of the chamber. These

were left when the chambers were reamed at the factory. The

goal is to polish out those tooling marks.

I have four

Ruger® single-action revolvers in .45 LC; two that I use for

Cowboy Action Shooting™ and two that I use for

hunting. When unloading

my cowboy guns I want the brass to fall out. For my

hunting guns I have

some fairly high-pressure loads that I use and are sometimes hard to

eject. These are

the cylinders that I want to polish.

Brownells

sells a cylinder hone specifically designed to polish chambers

in revolver cylinders called a Flex-Hone.

This is the correct tool for polishing chambers and

consists of small balls of polishing grit on the ends of a

spiral wire brush. The

Flex-Hone comes in two different grits, medium and fine.

The medium-grit hone is used to polish-out the tooling

marks, and the fine-grit hone is used to final-polish the

chamber. Brownells

states that you should only use their Flex-Hone

Oil as the cutting/lubricating agent, and that you should

not spin the hone any faster than 750 RPM.

This is well within the slow speed of my cordless

drill.

A word of

caution here; I do not want to polish the chambers mirror or

bearing smooth. When

the cartridge case expands, it needs something to grip

against, otherwise I could get excessive pressure.

First, I

used the medium Flex-Hone to polish out the tooling marks.

I put a few drops of Flex-Hone oil in the chamber,

chucked the hone into my cordless drill and ran the Flex-Hone

in and out of the chamber at slow speed.

It took about 10 minutes to polish out the tooling

marks. I added a

few drops of oil after every minute.

After every two to three minutes or so, I cleaned the

chamber and checked progress.

When I couldn’t see any tooling marks, I switched to

the fine Flex-Hone to final polish the chamber.

It took five minutes to final polish each chamber.

Each time, I put a few drops of the oil into the

chamber and ran the hone for about 1 minute, then added a few

more drops of oil.

Again, it

is somewhat difficult to tell from my photo, but the chambers

are now smooth after honing. I

placed a small white LED light in one of the chambers and you

can see the reflection of the head in that chamber.

Although

I have performed this procedure using a hand drill, I found

that using a drill press works much easier.

I wrapped a paper towel around the cylinder to pad it,

then put it in my machinist vise with the ratchet facing up.

I used a level to make sure the cylinder was straight.

I set my drill press to 720 RPM, locked the hone in the

drill press chuck and centered it over a chamber.

I lowered the hone into the chamber and added honing

oil, then turned on the drill press.

As the hone rotated in the chamber, I moved the quill

up and down. I

added a few drops of oil after every minute.

After ten minutes with the medium-grit hone, I moved to

the next chamber. After

all chambers were finished, I removed the cylinder and

thoroughly cleaned it, then put it back in the vise.

With the fine-grit hone I spent five minutes on each

chamber.

The empty

cases from the high-pressure loads I use in these revolvers

now eject easily. Prior

to polishing the chambers, the tooling marks would hold soot

and powder residue and I would have to spend a lot of time

scrubbing them out with a brush. Now,

just two or three patches soaked in powder solvent completely

clean the entire cylinder. Hey,

anything that makes a gun easier to clean is great by me.

|