Measurement Circuit and Numerical Processing of Chamber

Pressures

by Allen

Dominek and Eddie Dominek

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers. All tools were

purchased from Brownells

unless otherwise indicated.

Note:

Over the past few months I've

had an interesting, ongoing discussion with Allen Dominek

regarding measuring chamber pressure using strain gauges. He

has produced an excellent, and very technical article with

the results of his work and has kindly allowed me to publish

his article here. Enjoy.

Roy Seifert

The Kitchen Table Gunsmith

Introduction

The measurement of gun's

chamber pressure may provide useful diagnostic information

for load design and barrel performance. There are three

measurement techniques involved in chamber pressure

measurements [1,2].

Historically, the standard was a CUP measurement which

captured a peak chamber pressure using a compressible copper

pellet. A more recent technique using a piezo sensor yields

a more accurate measurement of not only peak pressure but of

the pressure in the barrel as the bullet is accelerated.

Both of these methods involve the modification of the gun to

install the sensor. The third technique uses a strain gage

which is placed over the chamber where the round is or at

some other location along the barrel. Hence, such a

measurement technique is non-invasive but not as accurate as

the piezo sensor technique. A strain gage is a small

electrical resistor which is sensitive to small compressive

or expansive forces that the supporting surface experiences.

A potential accuracy limitation does exist from the

analytical formulas used to relate chamber pressure to

strain and the placement of the sensor on the barrel.

Strain gages have been used for many years to measure

deformations. One early study is found here [3].

A commercially available strain sensor system is available

from Recreational Software, Inc. (RSI) [4].

Additional information on sensor preparation and measurement

technique is available at [5].

The

numerical data for the chamber pressure as a function of

time permits additional diagnostic capability. One example

is shown in [6].

Unfortunately, their mathematical derivation for a closed

formula expression relating terminal barrel velocity and

pressure is in error since it assumes a bullet velocity that

is increasing linearly as a function of time. It is this

work that made me interested in chamber pressure

measurements using strain gages.

The

following material outlines my activities for chamber

pressure measurements and numerical processing. The

activities include designing/building the pressure

measurement hardware and numerically processing the measured

data.

Pressure Measurement Hardware

When a round is fired in a

chamber, a complex chemical process (powder burning) occurs

to rapidly build up pressure to accelerate the bullet. This

pressure can be measured using a strain gage attached to the

exterior surface of the chamber since the chamber

approximates an open pressure vessel. There are expressions

relating the interior pressure of a vessel to the expansion

of the vessel. The rifle chamber geometry is not exactly a

traditional pressure vessel but these expressions can be

used to estimate the chamber pressure.

The

key to measuring this pressure is to be able to measure the

strain that the internal pressure exerts upon the barrel. A

strain gage provides an excellent sensor to do this. A

strain gage is an electrical resistor which changes its

resistance due to minute physical geometry changes [7,4,5].

The

measurement of this electric change requires the use of a

Wheatstone bridge. There are a number of different

Wheatstone bridge configurations available [8].

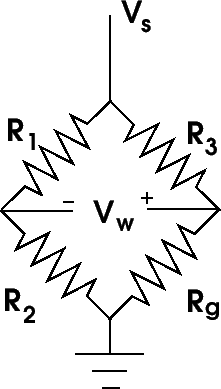

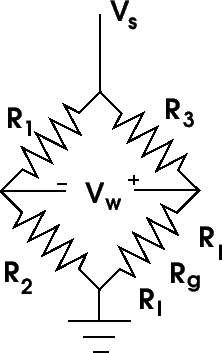

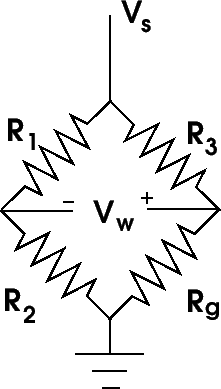

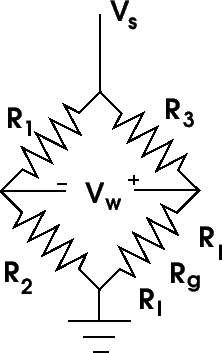

Figure

1 illustrates the typical resistive network. It consists

of three additional resistors with the strain gage.

Figure

1: Basic Wheatstone bridge.

When R1/R2 = R3/Rg

the resistance of the sensor changes and this voltage is no

longer zero since the bridge is no longer balanced. It is

this voltage that is measured to obtain the pressure inside

the chamber. The expression which relates voltage to strain

is given in Equation

1 ([8])

where

is the strain,

is the strain,

is the normalized measured Wheatstone bridge voltage Vw/Vs

with all the resistors equal R1=R2=R3=R

and Rg=R+∆R. The factor GF is the gage factor

which has a value of around 2. This value is provided by the

gage manufacturer and is the calibration factor for the gage

relating the normalized resistance change to the strain. The

gage factor is defined as

is the normalized measured Wheatstone bridge voltage Vw/Vs

with all the resistors equal R1=R2=R3=R

and Rg=R+∆R. The factor GF is the gage factor

which has a value of around 2. This value is provided by the

gage manufacturer and is the calibration factor for the gage

relating the normalized resistance change to the strain. The

gage factor is defined as

where ∆R is the resistance change of the strain gage.

Equation

1 was derived by expressing the differential voltage as

then setting R1=R2=R3=R and

solving for

using the GF relationship in Equation

2.

using the GF relationship in Equation

2.

When the Wheatstone bridge is physically realized, the

sensor is typically physically removed from the other

resistors and the impact of having connecting wires should

be addressed. Figure

2 illustrates the electrical model.

Figure

2: Wheatstone bridge with sensor wire loss included.

The

effect that the wires present is an additional loss

component. This loss is very small but so is resistance

change of the sensor. Equation

1 can be modified to account for this resistance and is

where Rl is the loss in one connecting wire.

In my application, these connecting wires are very short

(~6 inches in length) but still significant with respect

to the resistance change of the sensor as shown later.

For reference, 26 gauge copper wire has about 40

ohms/1000 feet and 30 gauge copper wire has about 100

ohms/1000 feet. Rl to be 0.02 ohms for 6

inches of 26 gauge wire and 0.05 ohms for 6 inches of 30

gauge wire.

Equations

1 and

4 can be simplified since the normalized Wheatstone

bridge voltage is very small. The loss of accuracy has

been numerically confirmed and it is negligible in this

application. The maximum normalized Wheatstone bridge

voltage for a higher power cartridge is of the order of

0.5 millivolt so Equation

4 can be approximated as:

However,

there is probably no reason to use this approximation with

today's numerical calculation resources. It does demonstrate

that the strain is primarily given by the first term and

that the contribution of loss from the connecting wires to

the strain gage is essentially a constant DC term which is

about 100 times smaller than the first term for the given

loss values.

There is a three wire sensor configuration [8]

where a second wire is attached to one of the sensor pads.

This is only effective for eliminating the loss in one of

the wires so I find it not helpful and not really of value

considering the size of Rl in my application.

Pressure/Strain Formulas

The next step is to relate

the measured strain values to the internal pressure of a

chamber. Approximate expressions can be found in [9].

The author attempted to relate the internal chamber pressure

to the external strain on the barrel using expressions for

thick and thin walled pressure vessels. The presentation was

technically weak and resulted in the use of equations not

appropriate for this application. These equations, however,

did provide numerical values that were realistic in

magnitude. A formulation to calculate the internal pressure

of a chamber using measured strain data is presented below.

It is a simple model and appears to be reasonable from the

experimental testing presented later.

Traditional cylindrical pressure vessels are called "open"

or "closed" A person may be tempted to classify a barrel as

a "closed pressure vessel" but it is not. A closed pressure

vessel has axial stresses induced by the internal pressures

of the cylinder since the ends of the cylinder are

physically constrained not to move. Also the classical

"closed pressure vessel" has a steady state pressure

throughout the cylindrical structure.

A

rifle barrel is not a closed pressure vessel in the

classical sense. Both ends are not mechanically constrained.

The muzzle end is free to move. Placing a strain gage

axially along the barrel will not sense any significant

axial deformation when the round is fired. This means that

the barrel can be modeled as an "open pressure vessel".

Additionally, the pressure that the barrel is exposed to is

transient in nature and not steady state (the entire barrel

is not under a uniform pressure). The pressure wave,

generated by firing the round, propagates down the barrel

and does not sense the finiteness of the barrel until the

pressure wave is at the muzzle. Until then, the barrel

appears to be infinitely long. However, when the pressure

wave does reach the muzzle, then additional interaction

occurs. FEM modeling [10]

confirms this simplistic model for early time.

There are a set of equations called Lame equations [11]

describing the stresses in a cylindrical structure when the

internal and external surfaces are under pressure. These

stresses can be grouped into three types: circumferential,

axial and radial. The only stress that is generated or is of

significance when a round is fired in a gun is the

circumferential stress.

The

circumferential stress equation of interest is:

where pi and po are the internal and

external cylinder pressures, u=ro/ri

is the ratio of the outer and inner cylinder diameters and

r is a position between ri and ro.

This equation is appropriate for what is termed "thick wall"

where the cylinder radii are explicitly used.

Equation

6 can be specialized for two geometries, one for the

barrel and one for the casing. In this model, the casing is

in contact with the barrel's inner diameter. Such a geometry

is typically called "compound cylinders". For the barrel,

Equation

6 yields

and

where

Us is the ratio of the outer and inner diameters

of the barrel where the strain gage is located and Pc

is the contact pressure between the ID of the barrel and the

outer diameter of the casing. Equation

9 is the pertinent equation for the casing:

where Pi is the internal pressure in the casing

(barrel) and Ub is the ratio of the outer and

inner diameters of the casing. Note that the subscript "s"

refers to "steel" which is what the barrel is made from and

the subscript "b" refers to "brass" which is what the

cartridge is made from.

The

desired equation to predict the interior pressure in a

barrel by the measured strain on the exterior of a barrel is

derived in two steps. The first step is to relate the change

of circumference at the contact interface between the barrel

and casing when a round is fired. Since both the barrel and

casing are in contact during firing, both have to expand the

same amount. This expansion is governed by the strain at the

interface and has to be continuous at the contact boundary

which requires:

The

strain and stress of a material are related through a

constant call Young's modulus or the modulus of elasticity,

$E$ and is expressed as:

Using

Equations

8 and

9 with Equations

10 and

11 yields:

where

the Young's modulus for steel (Es), brass (Eb)

and LDPE (shotgun shells) are 30*10^6, 16*10^6 and

$0.13*10^6 psi, respectively. The contact pressure is

determined by the strain gage reading. Using Equations

7 and

11 yields this contact pressure which is

Inserting Pc from Equation

13 into Equation

12 and reducing yields:

The

accuracy in determining the chamber pressure is dependent

upon many factors. From Equations

4 and

14, the factors are the measured Wheatstone bridge

voltage (dependencies of strain gage bonding/orientation,

the gage factor and amplifier gain), measured chamber/casing

dimensions and the Young's modulus material constants. The

only factors in which there are known uncertainties are the

strain gage bonding quality to the barrel and the Young's

modulus values.

The

dimensions used in Equation

14 should be the dimensions under pressure. Fortunately

for the amount of strain on the barrel, the change of the

barrel dimensions under pressure is negligible. However,

this is not the case for the casing. The outer diameter for

the casing should be the inner diameter of the chamber since

the case is in contact with the barrel during firing. This

results in a thinner case thickness during firing than the

case has under static conditions. The case thickness used in

Equation

14 is scaled from the unfired case thickness. This

scaling is based upon the fact that the amount of brass is

constant. The thickness used is given by t2=r1t1/r2

where the subscripts refer to the dimensions before firing

and 2 refer to the dimensions during firing. The change is

negligible since the casing diameter expands roughly

0.004''.

Differential Amplifier Circuit

Modern operational amplifier

(opamp) capabilities allow for very simple circuits to be

made with superior electrical performance. Figure

3 illustrates one circuit that can measure the

differential voltage generated by a Wheatstone bridge. A

Texas Instruments INA129 instrumentation opamp is a device

used to measure and amplify the generated differential

voltage created by the sensor and reject the common mode

voltage of the balanced bridge. The INA129 has the

capability to have an adjustable gain through the resistance

of R5/R6. This is important since

different chambers and loads will have different pressure

maximums. The gain is defined by 1+49.4k/R where R is either

R5 or R6. A gain of 101 is provided

when R6 is 500 ohms and a gain of 26 is provide

when R5 is 2k. Of course, the actual gain should

be measured to obtain the most accurate value for the gain.

The

required gain can be estimated by calculating the expected

pressures and voltages for various guns. The values shown in

Table

1 for a 22LR rifle, a 12 gauge shotgun and a 7mm Mauser

rifle are derived using Equations

12 and

13:

Calculated Wheatstone Voltages

|

Table 1:

|

|

Gun |

us |

pi (kpsi) |

*10^6 (psi)

*10^6 (psi) |

Vw (mV) |

|

22LR |

3.39 |

24 |

130 |

.35 |

|

12 gauge |

1.58 |

10 |

408 |

1.10 |

|

7mm |

2.19 |

48 |

738 |

1.99 |

Each gun requires a different amplifier gain if the maximum

measured voltage is to be the same. The amplifier gains for

the 22LR rifle, 12 gauge shotgun and 7mm rifle are 7100,

2300 and 1300, respectively, if the maximum measured voltage

is 2.5 volts. The current instrumentation opamp has a gain

limit of 10,000 but it is not good practice to use just one

amplifier to achieve large gains. Another stage should be

added. A fixed gain of 100 has been chosen for the second

stage and it will have a low pass filter to attenuate higher

frequency noise. The remaining gain will be provided by the

first stage. A jumper has been provided to choose between

two different gains of 25 and 100. These gains were chosen

before the values in Table

1 were confirmed. A more appropriate set of gains would

be 70, 22 and 12 or less.

All

the components operate on a 5 volt rail supplied by a 9 volt

battery (for portability) and a linear voltage regulator

ADM7150. Opamp REF5020 provides an offset voltage for the

instrumentation opamp output. Since the generated Wheatstone

bridge voltage will be positive (as configured), it is

necessary to offset the opamp output by a small voltage when

the bridge is balanced. This is achieved by offsetting the

INA129 output voltage by 2 volts using REF5020. The gain and

offset voltage should be set so that the maximum output

voltage is less than 4.5 volts for maximum sensitivity.

The

other opamp, an OPA320, provides the remaining gain. The

gain bandwidth product for this opamp is low so when a gain

of 100 is used, the gain naturally rolls off to minimize the

noise at the higher frequencies from being significant. The

roll off starts around 4-5 kHz which is the upper frequency

content limit of the signal of interest to be measured. From

numerical modeling, slightly better noise performance is

achieved when an OPA333 is used instead of an OPA320.

The

circuit uses another multi-turn potentiometer, R3, to

balance the bridge when the sensor has no strain on it. This

adjustment is made to have pin 6 the same voltage as pin 5

on the INA129 opamp when the strain gage is in its nominal

state. I make the adjustment so that the output voltage of

the second stage is the same voltage the reference voltage

provided by REF5020. If this is not done, the amplified

voltage may be railed (at 5 volts) since the gain of the

circuit is quite large.

A

number of connection points (H1, H2, H3 and PH1) are

present. PH1 provides for the connection of the 9v battery.

H1 is the connection point for the strain sensor. H3 is a

measurement point for both the pre-filtered (pin 1) and

filtered (pin 3) amplified voltage. Jumper H2 permits for

two discrete gain values to be chosen for the INA129

amplifier allowing maximum sensitivity depending upon the

peak chamber pressure.

Note that the measured voltage value used in Equation

1 has to be divided by the total gain of the opamp

circuit to recover the Wheatstone bridge voltage.

Numerical Processing

The velocity of the bullet

and its position in the barrel can be estimated once the

pressure in the chamber has been acquired. Note that the

following derivation is under ideal conditions which are not

met in a real life gun chamber/barrel. The calculated

quantities are based upon many assumptions. As previously

mentioned, the measurement and resulting pressure values

have limitations. In this section, no account of all the

energy created by the powder is attempted. Losses include

heating, friction and bullet dynamics.

The

force acting on a bullet is the gas expansion created by the

burning of the powder. Considering Newton's Second Law of

Motion as was done in [6],

the bullet's motion can be roughly modeled by equating its

mass and acceleration to the chamber pressure over its cross

sectional area as

where

m is the mass of the bullet, a is the acceleration, P is the

chamber pressure and A is the area of the bullet. Expanding

the a as the second time derivative of position yields:

since

Realizing

that:

results in Equation

16 becoming:

Multiplying both sides with dt and integrating yields:

where

v1 and v2 are the velocities of the bullet at times t1 and

t2, respectively. The integration approach used in [6]

is basically wrong. I feel that there is no value in

defining an average pressure as was done and the velocity of

the bullet is not linear so one cannot say that

What

can be determined by using Equation

20 is the velocity and position as a function of time by

piece-wise integrating this equation. This is readily

achieved since the measured data would be sampled with

small, uniform temporal spacings. The velocity is determined

by this equation:

where

∆t=ti-ti-1 and the position is

determine by this equation:

The

initial values for velocity and position are both zero. The

final velocity is the muzzle velocity of when the bullet

exits the barrel and the final position is the length of the

barrel starting from the location of the bullet before it

was fired.

There is one last consideration to make before calculating

velocities and travel distances which is the resistance the

bullet experiences traveling through the barrel. There are

two types of resistance to account for. One resistance is

the friction occurring between the bullet and the barrel and

the classical friction model is speed independent. The other

resistance is provided by the column of air that has to be

quickly displaced as the bullet is going through the barrel.

This resistance will be grouped into the friction resistance

since no measurements were made to isolate this resistance.

For

friction, there is a static and a kinetic friction. The

static friction is a friction that is over come by the

application of certain force (pressure*area). Once the

bullet has started to move, there is a kinetic friction

which is less than the static friction. These frictions

impacts the calculation of the velocity and travel distance.

These parameters (velocity and distance) can not be

calculated until the chamber pressure achieves a certain

level. At this level the bullet moves from the casing and is

forced into the barrel where the rifling ID is smaller than

the bullet diameter. At this point, kinetic friction is

important. Part of the force on the bullet created by the

chamber pressure is used to overcome this kinetic

resistance. This remaining pressure is used for the velocity

and distance calculations.

Data Collection

The pressure, velocity and

distance equations presented in the previous sections are

used with measured data. The first set of data was acquired

from the internet at [10].

The provided pressure curves were manually digitized. Three

other examples are presented that were acquired through the

circuit described above. The examples are for a Remington

Model 510 22LR rifle, a 12 gauge shotgun and a 7x57 mm

Mauser rifle.

A

Tektronix MDO3104 oscilloscope was used to measure and

digitally collect the amplified Wheatstone voltages. The

measured voltages were AC coupled to remove the DC offsets

in the measurements. There are two sources for the DC

offsets. One is from the offset generated by the REF5020 to

shift the signal from 0 volts (since the opamps were single

ended). The other offset is from the contribution of the

finite lead resistance shown in Equation

5. The alternate approach to account for these offset

would be to measure the DC voltage levels before the

cartridge is fired and subtract this level from the time

varying voltage measurements.

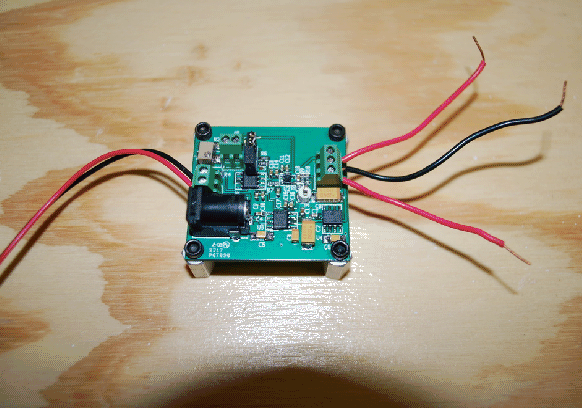

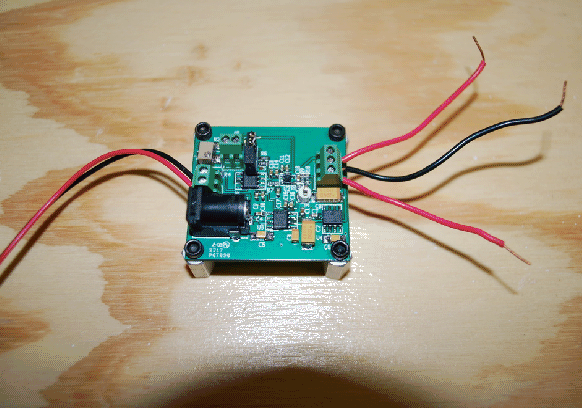

The

physical circuit used in the measurements is shown in Figure

4. A nine volt battery was used to supply power to the

circuit. The wires to the right provided measurement points

for the first and second stage amplifiers. The two position

terminal block on the top was were the strain gage wire were

attached.

Figure

4: The physical pcb used in the measurements.

The

static and kinetic friction forces were found using a

numerical downhill simplex optimizer. The optimizer found

the effective forces (pressures) which the calculated

velocities and distances matched measured values. The

measured velocities were provided by the ammunition

manufactures and the distances from the measured barrel

distances. The functional optimized was:

The

pseudo code illustrating how the effective friction forces

were determined is

if(pres\_meas > fric\_static) then

pres\_meas = pres\_meas - fric\_kinetic

continue to determine velocity and distance

end if

where

pres_meas is the chamber pressure found in Equation

14 and the friction values are determined through the

downhill simplex optimizer using the muzzle velocity and the

distance the bullet traveled in the barrel. The friction

forces are then calculated from the psi friction values by

multiplying them with the cross sectional barrel area.

Table

2 contains the various parameters that were used in the

calculations. The provided grain weight values were

converted to slugs for the calculations using a factor of

1\7000.*32.174=4.44*10^-6.

Physical Parameters used for the Numerical Calculations

|

Table 2:

|

|

Parameter |

22LR |

12 Gauge Shotgun |

7x57 Mauser |

|

Barrel ro (inches) |

.383 |

.642 |

.479 |

|

Barrel ri (inches) |

.112 |

.403 |

.225 |

|

Casing ro (inches) |

.112 |

.403 |

.225 |

|

Casing ri (inches) |

.102 |

.370 |

.185 |

|

Bullet OD (inches) |

.224 |

.686 |

.277 |

|

Bullet Mass (grains) |

40 |

492 |

140 |

|

Muzzle Velocity (fps) |

1035 |

1145 |

2660 |

|

Bullet Travel Length (inches) |

24.25 |

31.625 |

21.9375 |

|

Gain |

9880 |

2470 |

24.7 |

|

Young's Modulus (steel) |

30.*10^6 |

30.*10^6 |

30.*10^6 |

|

Young's Modulus (brass) |

16.*10^6 |

|

16.*10^6 |

|

Young's Modulus (LDPE) |

|

.13*10^6 |

|

Internet Data

Measured pressure values for

a 22LR rifle using a 40 grain, .224 caliber bullet in a

24.75'' long barrel can be found at [10]

for two loads. Figure

5 illustrates measured chamber pressure values using RSI

hardware and software for one of the loads. The reference

indicates that the pressure curve has been calibrated but

there is not sufficient information on how it was achieved.

Figure

5 : Measured pressure curve of a 22LR. The barrel pressure

dropped to zero at the end of the traces.

The

calculated velocity and position calculations using this

pressure curve are shown in Figures

6 and

7. Table

3 contains the resulting data.

Generated Data for a 22LR

|

Table 3:

|

|

Parameter |

Data |

|

Measured velocity (fps) |

1035 |

|

Measured length (inches) |

24.25 |

|

Optimized velocity (fps) |

1034 |

|

Optimized lenth (inches) |

23.18 |

|

Static friction (psi) |

39.9 |

|

Kinetic friction (psi) |

27.0 |

|

Static friction (lbs) |

1.57 |

|

Kinetic friction (lbs) |

1.06 |

Figure

6: Calculated bullet velocity in the 22LR barrel. Red: no

friction included; Green: friction included.

Figure

7: Calculated bullet position in the 22LR barrel. Red: no

friction included; Green: friction included.

Remington Model 510 22LR Rifle

Measurements for a 22LR were performed and Figure

8 illustrates the mounted strain gage.

Figure

8: Strain gage illustration for the Remington Model 510 22LR

rifle.

The

chamber pressures are shown in Figure

9 based upon a circuit gain of 9880. The maximum

measured voltage was 1.74 v which makes the maximum

Wheatstone bridge voltage .17 mv. The receiver prevented the

strain gage to be mounted over the casing of the round.

Hence, no peak chamber pressures could be acquired. Note

that there is a small pressure pulse before the main pulse

around t=.5 ms. All the 2LR measurements had this behavior.

Figure

9 :Chamber pressure for the Remington Model 510 22LR rifle.

12

Gauge Shotgun

The mounted strain gage for a

12 gauge shotgun is illustrated in Figure

10. The shell used was 2.75'' with a shot weight of

1.125 ounces, Winchester AA light target load. The measured

shot velocity using a chronograph was 1145 fps which is also

the manufacture's reported shot velocity.

Figure

10: Strain gage illustration for a 12 gauge shotgun.

The

chamber pressure is shown in Figure

11 based upon a circuit gain of 2470. The calculated

velocity and position calculations using this pressure curve

are shown in Figures

12 and

13. Table

4 contains the resulting data.

Figure

11: Chamber pressure for the 12 gauge shotgun.

Generated Data for a 12 Gauge Shotgun

|

Table 4:

|

|

Parameter |

Data |

|

Maximum measured voltage (v) |

2.27 |

|

Circuit gain |

2470 |

|

Maximum bridge voltage (mv) |

.91 |

|

Measured velocity (fps) |

1145 |

|

Measured length (inches) |

30.625 |

|

Optimized velocity (fps) |

1145 |

|

Optimized length (inches) |

30.79 |

|

Static friction (psi) |

626 |

|

Kinetic friction (psi) |

55.1 |

|

Static friction (lbs) |

231 |

|

Kinetic friction (lbs) |

20.4 |

Figure

12: Calculated shot velocity in the shotgun barrel. Red: no

friction included; Green: friction included.

Figure

13: Calculated shot position in the shotgun barrel. Red: no

friction included; Green: friction included.

7x57 mm Mauser Rifle

The mounted strain gauge for

a 7x57 mm Mauser is illustrated in Figure

14. A Federal SP round was used with a reported muzzle

velocity of 2660 fps.

Figure

14: Strain gage illustration for the 7x57 Mauser rifle.

The

chamber pressure is illustrated in Figure

15 with a circuit gain of 24.7. The red curve is

measured data taken from the output of the first stage since

the gain of the second stage was too large for this

measurement. The green curve is post-processed data using a

moving average. Note the pressure spike around .5 ms. This

is when the bullet left the barrel.

Figure

15: Chamber pressure for the 7x57 Mauser. Note the pressure

spike around .5 ms when the bullet left the barrel. The

green curve is smoothed data using the data in the red

curve.

The

calculated velocity and position calculations using this

pressure curve are shown in Figures

16 and

17. Table

5 contains the resulting data. Comparable results are

obtained using either the raw or smoothed data from Figure

15.

Generated Data for a 7x57mm Mauser

|

Table 5:

|

|

Parameter |

Data |

|

Maximum measured voltage (mv) |

47.2 |

|

Circuit gain |

24.7 |

|

Maximum bridge voltage (mv) |

1.91 |

|

Measured velocity (fps) |

2660 |

|

Measured length (inches) |

21.9375 |

|

Optimized velocity (fps) |

2659 |

|

Optimized length (inches) |

21.1 |

|

Static friction (psi) |

7849 |

|

Kinetic friction (psi) |

1446 |

|

Static friction (lbs) |

497 |

|

Kinetic friction (lbs) |

91.6 |

Figure

16: Calculated bullet velocity in the Mauser barrel. Red: no

friction included; Green: friction included.

Figure

17: Calculated bullet position in the Mauser barrel. Red: no

friction included; Green: friction included.

Conclusions

The expressions derived and

given here attempt to provide the chamber pressure from an

analytical approach. It is seen that friction is an

important factor in internal ballistics. This measurement

approach can provide data on the static and kinetic friction

for bullet/barrel interactions.

It

was also observed that a better Wheatstone bridge nulling

circuit, gain selection and amplifier configuration would be

useful. Nulling the Wheatstone bridge to an absolute null is

not critical as long as it is not too large to saturate the

high gain amplifier. The residual offset voltage can be

subtracted from the measurement or it can be blocked as was

done in these measurements with the oscilloscope set to an

AC input.

Figure

18 illustrates a possible nulling circuit. The nulling

circuit now includes two trimmers instead of one. These

trimmers provide a coarse and fine adjustment. This

adjustment could be made automatic if a processor was used

in conjunction with digital potentiometers.

Figure

18: Enhanced nulling circuit for the Wheatstone measurement

circuit.

The

amplifier configuration could also be changed to separate

the amplification from the low pass filtering. The low pass

filtering lessens the appearance of rapid pressure changes

and rapid pressure changes potentially could be missed as

was shown in the Mauser data. The current second amplifier

stage could have its low pass filtering feature removed and

a third stage added to provide low pass filtering with zero

gain. If a third stage is not added for noise reduction,

post processing with a moving average also could be used to

remove the high frequency noise.

The

observed chamber pressure characteristics were as

anticipated except for the chamber pressure not going to

zero once the bullet exited the barrel. This is bothersome

but could be attributed to the thermal heating of the barrel

and strain gage. A second strain gage could have been

attached on the barrel to replace the fixed resistor, R1, in

the Wheatstone bridge. This might have allowed a better,

more natural balance in the nulling circuit. Another

possibility for this behavior might be that the strain gage

was not properly attached to the barrels. A Loctite 401

adhesive was used.

All

the measured and calculated results depend upon the accuracy

of the obtained pressure values. Any measurement has

accuracy concerns. There are many measured parameters in

this effort. The parameters are the physical dimensional

measurements of the barrel and casing, the voltage

measurements and the material properties of Young's modulus.

Another accuracy consideration is that the numerical model

using a simple compound cylinder to approximate a physical

geometry (gun) may have its limitations.

Bibliography

-

Chamber Pressure, https://en.wikipedia.org/wiki/Chamber_pressure

-

Metallic Cartridge Chamber Pressure Measurement, http://www.chuckhawks.com/pressure_measurement.htm

-

Brownell, L.E., York, M., Sinderman, R., Jacob, K.,

Robbins H., "Absolute Chamber Pressure In Center-Fire

Rifles", The University of Michigan, Industry Program of

the College of Engineering, June, 1965, IP-710,

https://deepblue.lib.umich.edu/bitstream/handle/2027.42/3866/

bac6873.0001.001.pdf? sequence=5

-

Recreational Software, Inc., https://www.shootingsoftware.com/pressure.htm

-

Strain Gauges for Chamber Pressure Measurements,

http:www.ktgunsmith.com /straingauge.htm

-

Calculating Barrel Pressure and Projectile Velocity in

Gun Systems, http://closefocusresearch.com/calculating-barrel-pressure-and-projectile-velocity-gun-systems

-

Strain Gauge, https://en.wikipedia.org/wiki/Strain_gaug

-

Quarter Bridge, Half Bridge and Full Wheatstone Bridge

Strain Gauge Load Cell Configurations, Transducer

Techniques, https://www.transducertechniques.com/wheatstone-bridge.aspx

-

Strain Formulas, http://www.mindspring.com/$\sim$sfaber1/strnform3.htm

-

22LR Rifle and Tuner, http://www.varmintal.com/a22lr.htm

-

Thick wall stress formulas. http://www.engineeringtoolbox.com/stress-thick-walled-tube-d_949.html

2017-08-05

|