Performing an Action Job on a Ruger Redhawk

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers. All tools were

purchased from Brownells

unless otherwise indicated.

Introduction

I recently modified a Ruger Redhawk chambered in .45 Colt to

also fire .45 ACP by milling the ejector star (refer to my

article

Converting a KRH .45 LC Redhawk to shoot .45LC and .45ACP).

Now I wanted to perform an action job on this revolver.

An action

job consists of polishing all of the action parts where they

make contact to reduce friction and make the action

smoother. Certain angles and surfaces can also be modified

to make the trigger pull heavier or lighter. I had already

polished out some burrs in the frame where the hammer and

trigger were rubbing, so now I was ready to work on the

action parts themselves.

Just a

brief note about polishing – I constantly read that when

polishing you don’t want to remove any metal, just polish

the surfaces. Polishing, by its very nature, removes a very

small amount of metal to make the surfaces smooth. This

usually involves removing burrs or high spots, but not deep

pits or tooling marks unless absolutely necessary. The goal

is not to remove so much metal as to change the

angles or dimensions of the parts.

I viewed

a number of videos on You Tube to get some ideas on how to

perform an action job on the Ruger Redhawk, Super Redhawk,

GP100, and SP101 which all have essentially the same action,

but most were incomplete, and a couple are just downright

wrong.

Action

Cycles

Before polishing any surfaces, I wanted to get an idea of

how the hammer and trigger interacted in both single-action

and double-action modes so I could determine the surfaces

that would need polishing. I used a bench block and drilled

two holes to hold the trigger and hammer pivot pins. I also

drilled a 1/16” hole for a roll pin to keep the hammer from

moving too far forward, which simulated the frame. I

removed the pawl and transfer bar for clarity. The

placement of the holes may not be perfect, but they were

close enough so I could see what parts were touching during

both the single-action and double-action cycles.

With the

hammer and trigger at rest, the mainspring holds the hammer

against the frame and also holds the trigger forward. Note

how the trigger hook is between the hammer dog and hammer

hook. The Redhawk uses one spring as both the hammer

mainspring and trigger return spring. This is one reason

why the single-action trigger pull on a Redhawk is so heavy.

Pressing

the trigger to the rear begins the double-action cycle. The

top of the trigger hook presses on the bottom of the hammer

dog causing the hammer to begin to rotate. These two

surfaces need to be polished and lubricated.

At the

same time as the trigger begins to move, the cylinder bolt

drops down to unlock the cylinder, the pawl rises up to

engage the cylinder ratchet to rotate the cylinder, and the

transfer bar begins to rise up to cover the rear of the

firing pin. These parts are not shown but also need to be

polished to eliminate any friction.

As the

trigger is continued to be pressed to the rear, the hammer

movement is transferred from the top of the trigger hook and

the hammer dog to the bottom of the hammer and the

double-action sear on the trigger. These two surfaces will

also need to be polished and lubricated. The point of the

double-action sear needs to be gently rounded so it won’t

gouge the bottom of the hammer.

The

cylinder bolt is released and a spring and plunger causes it

to pop up and rub against the cylinder creating a drag

ring. The pawl continues to rise causing the cylinder to

continue to rotate, and the transfer bar also continues to

rise.

In the

final stage of the double-action cycle, the trigger has been

pressed to the point where the double-action sear is just

ready to release the hammer. As the trigger continues to

move to the rear the sear releases the hammer and the hammer

falls. These surfaces need to be polished and lubricated,

but the angles should not be changed.

Just

before the hammer falls, the cylinder has been rotated

enough that the bolt falls into a bolt notch in the cylinder

which locks the cylinder in place, and the transfer bar is

high enough to engage the rear of the firing pin.

Releasing

the trigger after the hammer falls causes the single-action

sear on the trigger to depress the hammer dog. As the

trigger moves forward the single-action sear presses on the

hammer dog causing the dog to rotate.

When the

single-action sear on the trigger clears the end of the

hammer dog, a spring and plunger behind the hammer dog

causes the hammer dog to pivot to the front thereby

resetting the action. Again, where surfaces meet and rub

together, they need to be polished and lubricated. As the

trigger moves forward, the pawl and transfer bar are lowered

to their reset positions.

Nestled

inside the trigger assembly are the cylinder bolt and the

trigger plunger. The trigger plunger causes the bolt to

rotate down which unlocks and releases the cylinder. When

the trigger is released and moves forward, the angled front

of the trigger plunger rides against a cam on the rear of

the bolt causing it to move backwards. The end of the

spring for the pawl plunger also rides against the rear of

the trigger plunger and causes it to move forward and slide

over the bolt cam in preparation to rotate the bolt at the

beginning of the next cycle.

The

engagement surfaces on these two parts need to be lightly

polished where shown. Over-polishing these two parts will

affect the timing of the bolt. The sides of the bolt and

trigger plunger can also be lightly polished; just enough to

remove roughness and high spots, but not mirror smooth or

the dimensions will be changed. All surfaces that touch

need to be cleaned and lubricated after polishing.

To begin

the single-action cycle the hammer is pulled to the rear.

The top of the single-action hammer hook presses against the

underside of the trigger which causes the trigger to begin

moving to the rear. The underside of the single-action sear

on the trigger, and top surface of the single-action notch

on the hammer need to be polished and lubricated.

As

before, when the trigger begins to move, the bolt falls

unlocking the cylinder, the pawl and transfer bar begin to

rise and the cylinder begins to rotate.

As the

hammer continues to be pulled to the rear, the single-action

sear on the trigger falls into the single-action notch on

the hammer. Mainspring pressure holds the hammer notch

against the trigger sear. When the trigger is pulled, the

sear moves out of the notch allowing the hammer to fall.

The ledge of the single-action notch on the hammer can be

reduced to remove single-action drag, and the sear and notch

need to be polished glass-smooth.

When the

trigger is pressed, the single-action sear moves out of the

single-action notch and the hammer falls. When the

trigger is released the action resets.

It is

important to note that the hammer comes back farther in

single-action mode (shown in blue in the above photo) than

in double-action mode. That means the hammer has less

striking force against the firing pin in double-action

mode. When I replace a mainspring I always test with CCI

primers to see if they will fire in double-action mode. CCI

primers are the hardest in the industry, and the hammer has

less energy in double-action mode.

Polishing

Tools

I used the following tools to polish the trigger and hammer:

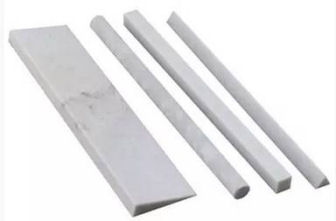

·

400 and

600-grit narrow polishing sticks – available from

Boride Engineered Abrasives. They make a gunsmithing

kit with coarse and fine, wide and narrow polishing sticks

that I have used on many guns. Oil is used to clean these

polishing sticks.

·

Fine

Arkansas stone – available from Brownells. They make a

4-stone set

#975-104-000 that comes in different shapes perfect for

gunsmithing use. Oil is used to clean these stones.

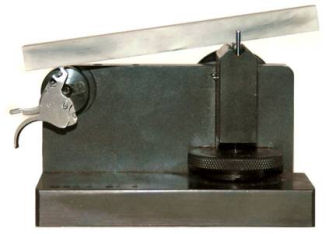

·

Power

Custom Series I Stoning Fixture – The proper tool for

polishing the trigger sear. Available from MidwayUSA.com,

#743549, this jig ensures that surfaces are kept flat

and square.

·

Ruger

Redhawk Adapter for Power Custom Series I Stoning Fixture –

This adapter fits the Series I stoning fixture and sets the

Ruger Redhawk trigger in the proper position so the

single-action sear can be polished. This is also available

from MidwayUSA.com,

#335275.

·

Ceramic

Polishing Sticks, White, Extra Fine – Available from

Brownells

#080-721-601 used to polish the single-action sear.

Water is used to clean a ceramic stick.

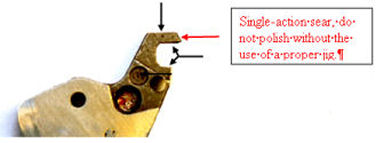

Polishing

the Single-Action Sear

I

installed the Redhawk adapter onto the Power Custom Series I

stoning fixture. I removed the pawl and plunger and the

trigger plunger from the trigger and mounted it onto the

adapter. I marked the sear with a blue marker to ensure I

was polishing the surface flat. I used the white extra-fine

ceramic stick to polish the surface. When the stick became

dirty I used water to clean it.

It is

possible to change the angle of the single-action sear to

increase or decrease the single-action trigger pull. A

small change in angle goes a long way so must be done very

carefully in very small increments. The Power Custom Series

I stoning fixture is designed so that moving the adjustment

wheel changes the angle of the stone against the sear.

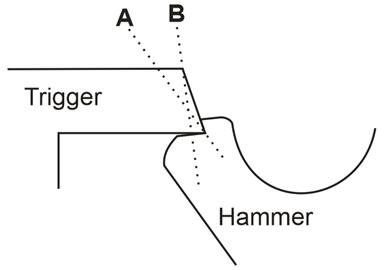

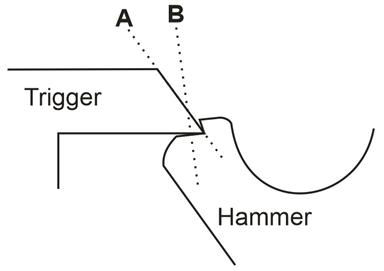

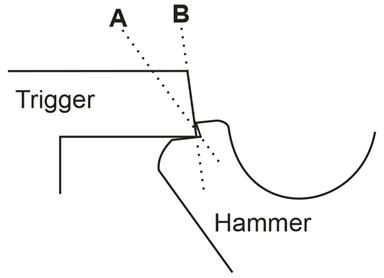

Changing

in the direction of angle A will make the trigger pull

heavier. In this situation the trigger is actually causing

the hammer to rotate which is called “hammer push” which

results in a heavy trigger pull. Notice the gap between the

sear and the hammer notch.

Changing

in the direction of angle B will make the trigger pull

lighter. If this angle is too large the hammer could slip

off of the sear causing a very unsafe condition.

I decided

not to change the angle in any way on my revolver. I

certainly didn’t want to make the single-action trigger pull

any heavier than it already was, and I didn’t want to risk

making the revolver unsafe; especially since I reduced the

height of the single-action notch on the hammer.

Reducing

the Single-Action Notch

The

single-action trigger pull had a bit of creep which I wanted

to remove. I used a 400-grit polishing stone and reduced

the notch on the hammer to 0.010”. I marked the lip with a

blue marker and carefully stoned the lip until the notch was

reduced. This was a trial and error process; I reduced the

lip by about 10-20 strokes with the stone, then reassembled

the gun to test for creep. Reducing the notch and replacing

the mainspring with a 14# mainspring reduced to

single-action pull to 4-pounds, 4-ounces.

Polishing

Hammer Bottom

Next I

used a 600-grit polishing stick to polish the bottom of the

hammer. This is where the double-action sear rides and

needed to be smooth.

Polishing

the Hammer Dog

I used a

rubberized polishing tip and my high-speed rotary tool to

polish the top and bottom edges of the hammer dog. There

are no critical angles here so the power-tool worked great.

I made sure the polishing tip was flat against the bearing

surfaces.

Polishing

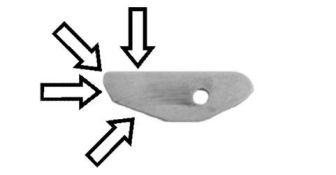

the Trigger Hooks

The

trigger hooks needed to be polished in the areas shown in

the above figure. These surfaces make contact with the

hammer in both single-action and double-action modes. I

didn’t touch the single-action sear because I had already

polished this using a proper jig.

Replacing

the Mainspring

I purchased a Wolff Redhawk spring kit from MidwayUSA.com

#139298 which contained a 12#, 13#, and 14# mainspring.

The factory is 19#. Originally I had installed the 12#

spring, but that wouldn’t ignite .45 ACP cartridges in

double-action mode. I installed the 14# spring which now

reliably ignites the .45 ACP cartridges.

Reassembly

I lubricated all moving parts with CLP and put Brownells

Action Lube Plus

#083-050-002 on the single-action sear, hammer notch,

and double-action sear and hammer surface. I dry-fired the

gun over 100 times to wear-in the parts I just polished;

especially the single-action sear. The double-action is

smooth and the Ruger design prevents stacking. Stacking is

where the trigger pull gets heavier at the end of the

double-action cycle.

Results

The single-action trigger pull is now crisp with no

perceptible creep or drag. It’s still heavy and takes a bit

of getting used to, but it is very acceptable and the gun is

a pleasure to shoot.

Please

note that Ruger takes a dim view of performing any

modifications to their firearms; especially to the action.

If I was to ever have to send the Redhawk in for service,

chances are all my polished and/or modified parts would be

replaced with factory parts and I would have to start all

over.

|