Converting a Rossi 62SAC to Shoot .22 Short,

Long, and Long Rifle Cartridges

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

A few years ago I purchased a Rossi 62 SAC gallery gun.

This is a pump-action rifle that shoots .22 long rifle

(LR) cartridges only. This

rifle is patterned after the

Winchester

62A that was designed to fire .22 short, long, and long rifle

cartridges. As a

teenager I spent many an hour, and many a dollar at the county

fair shooting gallery shooting .22 shorts out of these rifles,

which is why I think I bought it in the first place; out of

nostalgia.

I

wanted to know what the difference was between the Rossi that

only fed .22 LR cartridges, and the original

Winchester

that fired .22 short, long and long rifle cartridges.

In my gunsmith library I have the excellent National

Rifle Association (NRA) firearms assembly books.

By the way, if you are reading this article and are a

firearms collector and/or shooter, you should be a member of

the NRA. No other

organization will protect your shooting and gun-ownership

rights like the NRA…enough said.

Since the Rossi is a copy of the

Winchester

, I looked up the

Winchester

62A.

I also found an article in

Gunsmithing the Rifle:

Fixes

& Upgrades for the Precision Shooter (American Gunsmith

Library) titled

The Rossi Gallery Rifle

by Butch Thomson that explained how

this little rifle worked, and how to correct problems.

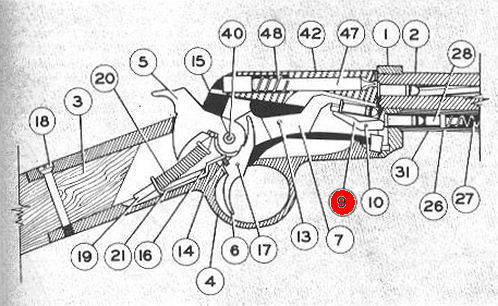

In

the above sectional diagram,

item #9 the “cartridge stop” was the piece missing from

the Rossi. In the

Winchester

, when a cartridge is fed from the magazine tube under spring

tension, the rim hits the rear of the cartridge stop causing

the front to pivot up to block the next cartridge from feeding

onto the carrier. This

piece was designed to pivot regardless of the length of the

cartridge hitting it.

The

Rossi carrier had the hole for the pivot pin, and the center

of the carrier was milled to accept the cartridge stop, but

the front of the carrier was solid.

It would have been slotted to accept the bottom of the

stop. The carrier

itself was long enough to allow .22 LR cartridges to feed.

If a shorter cartridge entered the carrier, the

following round was partially fed onto the carrier from the

magazine tube. This

was because there was nothing to stop that following cartridge

from feeding. When

the carrier was attempted to be raised, the partially fed

cartridge would get jammed between the front of the carrier

and the receiver, thereby stopping the action.

So, can I get the Rossi to feed .22 short, long, and

long rifle cartridges by installing the cartridge stop into

the carrier?

Numrich

Gun Parts Corporation was the first place I checked for

parts. I thought

if I could replace the Rossi carrier with a

Winchester

carrier assembly that might be the best solution.

Unfortunately, they were sold out of the carrier

assembly, but I was able to purchase just the cartridge stop

and pin. So, I had

to mill the Rossi carrier and fit the cartridge stop.

Apparently

the earlier Rossi model was designed to shoot .22 short, long,

and long rifle and had this part, but it was so problematic

that the later models did not.

According to Butch Thomson’s article most of the

problems related to the cartridge stop were caused by poor

fitting, which could be remedied by proper fit and polishing.

Disassembly

To get to the carrier I completely disassembled the rifle.

I removed the butt stock by first removing the tang

screw and pulling the butt stock off of the receiver.

Next I loosened the takedown screw and split the

receiver. I cocked

the hammer and put a small pin through the hammer strut

retaining hole, then pulled the trigger.

The pin prevented the hammer from falling which

relieved any spring tension from the hammer.

I carefully removed the retaining pin from the takedown

screw. This pin

actually slid out fairly easily, then I removed the takedown

screw. Finally I

removed the disassembly bushing and the hammer and carrier

came out of the receiver.

Carrier

I

removed the carrier lever spring screw and spring.

I would have removed the carrier lever as well but I

couldn’t remove the pin.

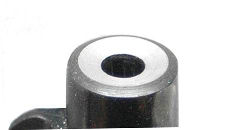

As you can see from the above photo, the center of the

carrier is slotted for the cartridge stop and the hole for the

pivot pin has been drilled.

However, the front of the carrier is solid.

I had to extend the slot in order to install the

cartridge stop. Notice

the narrow, flat piece extending from the front and below the

carrier. This

piece is an integral part of the casting, not a separate

piece. Its purpose

is to prevent cartridges from feeding from the magazine tube

when the carrier is in the raised position.

When I milled the slot extension, I had to make sure I

left enough of this piece so other cartridges would not feed.

I

set the cartridge stop on the outside of the carrier and used

a drill bit to align the holes.

This showed me just how deep I needed to mill the slot.

The

slot measured 3/32” so I used that size square end mill bit

to extend the slot. I

found I also had to remove a small amount of metal from the

rear of the protruding edge, and use a 1/4” bit to deepen

the carrier so the cartridge stop would rotate.

After

milling I removed burrs and flashing with jeweler’s files

and installed the cartridge stop in the carrier.

To ensure the pin didn’t fall out I used a prick

punch and punched the center of the pin while it was in place.

This expands the end and makes it tight in the hole.

I lubricated all parts and reassembled the rifle.

To my surprise, it fed .22 short and long rifle

cartridges without a hitch.

However, it doesn’t seem to feed mixed cartridge

lengths reliably. That’s

alright since I probably won’t be mixing different length

cartridges anyway.

Muzzle

No,

the above photo is not an optical illusion.

That’s exactly how the muzzle looked.

I couldn’t tell if the bore was drilled off center,

or if it was just a poor muzzle crown.

Because the end of the muzzle was not square accuracy

could be adversely affected.

I never fired this rifle for accuracy, but it seemed to

do alright against soda cans at 15 yards, so accuracy was at

least as good as “minute of pop can”.

To enhance accuracy I re-crowned the muzzle.

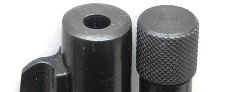

A

professional gunsmith uses a lathe to cut a new crown, but I

don’t have a lathe. I

used a 79-degree crown cutter I purchased from Brownells

to cut the crown by hand.

This cutter makes an 11-degree recessed target crown,

but I used a 1/2-inch diameter cutter – smaller than the

diameter of the barrel – so I wouldn’t cut out to the edge

of the barrel. I

installed the .22 pilot, handle, and a 1/2-inch stop collar

onto the cutter. The

stop collar made the final cut smooth, rather than uneven with

chatter marks. In

the photo above the stop collar is set back to show the

cutting teeth. I

adjusted the collar so it was almost flush with the front of

the cutter.

I

lubricated the pilot and cutting teeth with cutting oil and

turned the cutter clockwise.

I turned the cutter only in one direction; otherwise I

could break the teeth. I

cleaned chips off of the cutter and muzzle and lubricated the

cutter frequently. The

above photo shows just how unevenly the muzzle crown was

originally cut. Notice

the high spot that was cut first.

I

cut until the stop collar touched the front of the barrel.

You can see the nice, clean muzzle in the above photo.

It turned out that the bore was not off-center; instead

the crown was just poorly cut.

Finally,

I blued the exposed crown with cold blue to prevent the metal

from corroding. I

degreased the crown with acetone, plugged the bore, then

immersed the muzzle in Van’s

Instant Gun Blue for about 5 minutes.

I wiped off the excess bluing solution, then treated

the metal with gun oil to stop the bluing process.

The above photo shows the result.

Summary

So why would I even want this rifle to feed .22 short, long,

and long rifle cartridges in the first place?

First of all was the gunsmithing challenge to see if I

could do the conversion, and second was to increase the

flexibility of this rifle.

This project was more than just replacing parts; it

involved true gunsmithing.

I may never shoot shorts or longs out of this rifle,

but again, it was the challenge of the project.

|