Replacing a Ruger® Single-Six® Firing Pin

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

I recently converted a Ruger Single-Six into a trail gun

(refer to my article

Building the Ulitimate .22 Trail Gun). In the

process of dry-firing the gun the firing pin broke. Because

the firing pin on a Single-Six is blocked from protruding

too far it won’t peen the tops of the chambers, so I thought

there wouldn’t be any problem dry firing.

I

purchased this gun in 2003 and it was very rough compared to

a Single-Six I purchased in 1977, so I suspect this gun was

built during a time of high volume production and low

quality, so it didn’t surprise me that the firing pin broke!

The

firing pin sits in a bushing (Ruger calls this a recoil

shield) that is held in place by a cross pin. The cross pin

is not installed horizontally; it is installed at an angle.

There is a hole in the loading gate notch in the frame; this

is one end of the cross pin. The other end of the pin is

blended with the frame so it is difficult to see. First I

took a prick punch and marked the position of the recoil

shield in the cylinder frame. This was so I could get the

recoil shield rotated correctly when replacing it in the

frame. Then I took a punch and drove out the cross pin from

the hole in the loading gate notch through the frame.

I

completely disassembled the gun and tried to drive the

recoil shield out of the cylinder frame by applying a punch

to the rear of the broken firing pin, but all I succeeding

in doing was peening the frame so the firing pin wouldn’t

move anymore. I poured some Kroil oil into the firing pin

hole to loosen up the recoil shield and waited a couple of

hours. After soaking I used a heavy ball-peen hammer to

strike the punch and the recoil shield came right out.

After I removed the recoil shield I took a proper size drill

bit and reamed the firing pin hole in the frame. This

removed any burrs left by the punch.

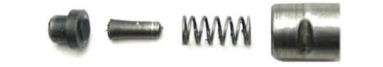

I ordered

two spare firing pins from Brownells

#780-001-132 just in case I broke another one. When the

parts arrived I reassembled the firing pin, rebound spring,

and recoil shield and started them into the hole in the

frame. I lined up the two marks I made with the prick punch

and inserted a brass rod through the bore so it touched the

front of the recoil shield.

Because

this was a .22 the recoil shield was not directly in line

with the bore so my brass rod only touched the bottom of the

recoil shield as shown in the above photo. Tapping on the

brass rod caused the recoil shield to become tilted. I took

a brass punch and also tapped on either side of the recoil

shield to ensure it was being seated straight. I continued

tapping the bottom and sides until the recoil shield was

back into position, then inserted the cross pin into the

hole in the loading gate notch. Even though the cross pin

was originally flush with the frame, I left it sunk a bit

below the surface. I applied a drop of oil to the front and

rear of the firing pin to ensure the parts were sufficiently

lubricated.

I took a

400-grit polishing stone and polished the front of the

recoil shield and frame to ensure these surfaces were flush

and smooth. This was to ensure the cylinder would rotate

freely with no binding. Now my trail gun is back in

service, but I probably won’t be dry-firing it very much!

By the way, this is the same process for pretty much any

Ruger single-action revolver.

|