Initial Inspection

When I received the revolver, I performed an inspection like I do for

all firearms that I purchase.† The gun

was clean (surprise!); the frame and crane were strait, ejector rod was not

bent, and the bore was clean and bright.†

There did not seem to be any problems with timing.† The grips were after-market and did not allow

easy use of a speed-loader.

I immediately noticed that the slots in the screw heads were wobbled,

indicating someone used the wrong sized blade to remove them, and there were

scratches on either side of the yoke screw.†

These are strong indications that someone had been inside.

One major problem I discovered was that the revolver experienced hammer

push-off. †With the hammer cocked in single-action

mode, when I pushed on the hammer with my thumb, it released from the sear and

fell.† This is a very dangerous situation!† Someone probably tried to polish the sear

without using the proper jig and rounded it.†

Many comments on the Internet said to cut off the hammer spur to make it

into a double-action only firearm, but I wanted the gun to function as designed.

Disassembly

Before disassembling the revolver, I watched GunBlue490ís video Disassembly and Care of the S&W Revolver

~ Learn how to from a Factory Trained Armorer!†

Here is the link to that video:

https://www.youtube.com/watch?v=4ujyLn3lHBc

I disassembled the revolver following GunBlu490ís video.† Brownells sells specific

screwdriver bits made to fit S&W revolver screws.†

https://www.brownells.com/gunsmith-tools-supplies/general-gunsmith-tools/screwdrivers-sets/magna-tip-bit-sets/s-w-combo-bits-only-sku080087002-406-42598.aspx?rrec=true

†I always use the correct screwdriver bit

that fits the screws so I donít bugger them.† I used these bits to remove the screws and prevent

any further damage to them.† I did

purchase a new set of screws (see below) because I wanted the gun to look good,

not buggered.

Inside I discovered the moving parts were coated with an excessive

amount of oil, some of which had congealed into a sticky goo.† I used acetone to remove the residual oil and

generally clean the inside.

Polishing the Sear

Warning:† Do not attempt to polish the sear without a

proper jig.† Polishing the sear by hand

can cause rounding of the sear and a dangerous, unsafe condition.

There are several incorrect videos

on YouTube showing how to polish the sear by hand.† This should never be done without a jig as

mentioned above.† MidwayUSAís Larry Potterfield has an excellent and correct video called Gunsmithing - How to Lighten and Smooth the

Trigger Pull on a Smith and Wesson (S&W) Revolver.† Larry shows how to polish the internal action

parts of the revolver.† Here is the link

to that video:†

https://www.youtube.com/watch?v=HJ6Hb89lVXw

†

I examined both the sear on the trigger, and sear notch on the

hammer.† The sear notch was very shallow,

but still looked sharp under a magnifier.†

The sear on the trigger, however, was rounded.† The hammer and sear are case hardened, but

the hardening only goes 4-6 thousandths deep, so any polishing must be very light,

and not aggressive to break through the hardening.

I installed the K, L, N adapter onto my Power Custom Series I Stoning

Fixture as shown in Larryís video.† The

adapter and fixture are both available from

Brownells and

MidwayUSA.† The instructions that came with the jig

stated to move the adjustable guide up 20 clicks.† I coated the sear with blue marker to ensure

I was polishing the sear flat.

Long ago I had purchased medium-fine and extra-fine ceramic stones from

Brownells for polishing hammers and sears.† These stones use water as the cutting/cleaning

agent.†

https://www.brownells.com/gunsmith-tools-supplies/metal-prep-coloring/stones/6-x-1-2-x-1-2-ceramic-stones-prod799.aspx

I used the medium-fine stone to reshape the sear nice and flat so the front edge was sharp.† I final polished with the extra-fine stone to

get a mirror polish.

Reassembly

I lubricated the inside of the revolver as shown in GunBlu490ís video

and reassembled the revolver.† I used BreakFree CLP as the lubricant because it leaves behind a

very thin coating of Teflon.† I installed

a Wolff K, L, N spring kit which reduced the double-action trigger pull from 7 lbs 8 oz to 5 lbs 2 oz.† The revolver now functions correctly with no

hammer push-off.† Hopefully, I didnít

remove the case hardening from the sear so it wonít accelerate

wear.

New Screws

I purchased a set of stainless-steel frame screws from eBay for $25.00

which I thought was very reasonable.† I

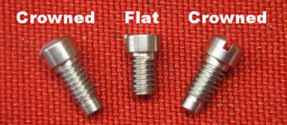

just didnít like the look of the buggered screw heads.† The set consisted of two crowned side plate

screws, and one flat-head side plate screw.†

The flat head screw fits underneath the grip, the two crowned screws fit

in the other two holes.†

Fitting the Yoke Screw

The front screw is also the yoke screw and must be fitted so the bottom

of the screw doesnít touch the yoke causing it to bind.† The sides also cannot bind against the groove

milled in the yoke.† The yoke must be

able to rotate freely with a minimum of front to back movement.

When I attempted to install the yoke screw into the frame

without the cylinder and yoke installed, the screw was very tight in the

threads.† When I examined the original

yoke screw, I noticed that the threads were flat, not sharp like the new screw.

I wrapped a piece of 320-grit wet/dry sand paper around the

threads, pinched it between my thumb and finger, and used a screwdriver to turn

the screw back and forth a few times to flatten the threads.† I cleaned the threads with alcohol and tried to

screw it into the frame.† The first time

the screw was still tight, but after a second time the screw fit with no

problem.

As mentioned before, when manufactured, the yoke screw is

the same length as the crowned side plate screw.† However, it is too long to serve as the yoke

screw.† If installed as is, the end of

the screw will rub against the yoke causing it to bind.† I coated the end of the screw with a marker

and rubbed it on the 320-grit wet/dry paper to reduce the length, then installed

the screw to test the fit.† I didnít

tighten the screw; I turned it down until I just felt some friction.† I opened and closed the cylinder and if I

felt any binding, I removed more metal from the end of the screw.† I continued to remove metal and test fit until

I could tighten the screw and open and close the cylinder with no binding.

Because this screw is now fitted it must be installed in

this position.† Installing the other

crowned screw in the yoke screw position will cause the cylinder to bind.

There now, doesnít that look better?† Eventually I will probably try to buff out

the scratches, but that is a project for another time.† I also installed a Hogue mono-grip because I

like the look and how it feels in my hand.†

Other folks donít like the rubber grips because they catch on clothing

when carrying concealed, but I wanted to try them out.† The wood grips that came with the gun caused

speed loaders to bind, but the rubber grips do not get in the way of the speed

loaders.

Conclusion

Working on trigger sears should NEVER be attempted without

the proper jig.† Yes, these tools are

expensive, but not nearly as expensive as replacing damaged parts.† And using proper sized screwdriver bits

prevents screw heads from becoming buggered.†

Damaged screw heads are a sure sign of amateur work.