Tools

Most

kitchen table gunsmiths

damage good firearms beyond repair often because they don't

have the right tools. Here is a basic list of tools I

use to work on my own guns. This list is by no means

complete, and I didn't purchase them all at once. I

purchased them as I needed them for a particular

project. Let's face it, tools can be expensive, but

they're a lot cheaper than paying someone else to do the

work. I pay for a tool once, then I have it for future

projects. Polishing

Stones Polishing

Stones

I use polishing stones of different shapes and sizes

depending on the part I'm working on. I really can't

have enough of these very important tools. You can get

them from Brownells,

Midway USA, and a company called

Boride

Abrasives as shown in the photo.

Hollow-Ground Screwdrivers

- Nothing will ruin screws quicker than taper-ground, hardware

store screwdrivers. These blades have a tendency to jump

out of the screw slot and mar the heads. Hollow-ground

screwdrivers are ground with parallel sides so they fit the

screw head properly. Used correctly they do not slip out

of the screw slot. Here is a nice set available from

Midway USA.

Files

- Files are the second most important tools I own for working

on firearms. I can purchase them at any hardware store

or home improvement center. I've also needed some specialty

files like 60 and 65 degree sight dovetail files or others as

the job requires. I always make sure I have some chalk

and a wire brush. I rub chalk into the file, which keeps

the teeth from getting full with metal chips. I use the

wire brush to clean the file, then re-chalk. Most files

are designed to be used in one direction only. I have

broken the teeth off of files by moving them back and forth. Files

- Files are the second most important tools I own for working

on firearms. I can purchase them at any hardware store

or home improvement center. I've also needed some specialty

files like 60 and 65 degree sight dovetail files or others as

the job requires. I always make sure I have some chalk

and a wire brush. I rub chalk into the file, which keeps

the teeth from getting full with metal chips. I use the

wire brush to clean the file, then re-chalk. Most files

are designed to be used in one direction only. I have

broken the teeth off of files by moving them back and forth.

Jeweler's Files -

Sometimes called needle files, these are great for doing fine

work in small places where I don't need to remove a lot of

material. I purchased mine at my local home improvement

store. I have also found them in electrical supply

stores and hobby stores.

Punches

- I have a number of different punch sets; steel, brass, and

roll-pin. I use steel for regular pins, and brass for

when I don't want to mar the object such as when I'm

installing sights. A roll-pin punch has a raised dimple

in the middle of the face of the punch. This dimple fits

into the hole in the center of the roll-pin, which keeps it

from slipping off. Lyman sells a punch set that comes

with a mallet. The mallet has three types of heads;

steel, brass, and nylon.

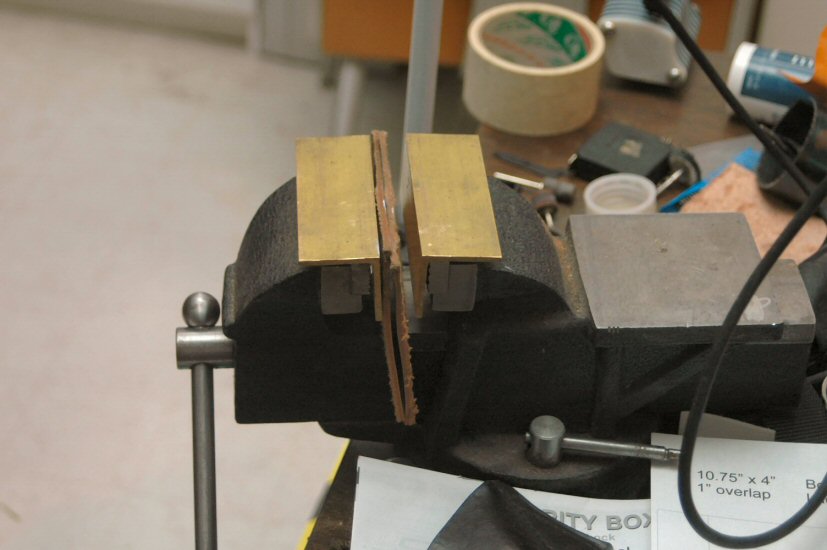

Vise

- I discovered early on that I needed a good 4-inch vise to

hold my work. Here you can see my vise with bronze vise

jaws available from Brownells. I have also padded my

jaws with leather to protect the finish of any firearm on

which I'm working. Before I had a permanent place to

work I mounted the vise to a block of wood and used C-clamps

to mount it to my kitchen table. Vise

- I discovered early on that I needed a good 4-inch vise to

hold my work. Here you can see my vise with bronze vise

jaws available from Brownells. I have also padded my

jaws with leather to protect the finish of any firearm on

which I'm working. Before I had a permanent place to

work I mounted the vise to a block of wood and used C-clamps

to mount it to my kitchen table.

Bench Block - A bench block is a soft disk made of wood or

nylon used for removing pins. It has holes and grooves

for holding parts, or I can drill my own holes if

necessary. The bench block at left is make by Wheeler

Engineering available from Midway USA.

Dial

or Digital Calipers - When working on firearms there are

some procedures that require precise measurements. A

good dial or digital calipers is the correct tool to

have. I have also needed other measuring tools for

different projects, but as stated before, I purchased them

when I needed them. Dial and digital calipers are

available at hardware and home improvement stores, Midway USA

and Brownells. Dial

or Digital Calipers - When working on firearms there are

some procedures that require precise measurements. A

good dial or digital calipers is the correct tool to

have. I have also needed other measuring tools for

different projects, but as stated before, I purchased them

when I needed them. Dial and digital calipers are

available at hardware and home improvement stores, Midway USA

and Brownells.

High

Speed Rotary Tool with Flexible Shaft - I have found a

high-speed rotary tool is invaluable for working on

firearms. However, many professional gunsmiths call the

rotary tool their best friend for bringing them

business. These tools rotate at speeds of 25,000 RPM or

more and can easily damage a firearm beyond the capabilities

of the kitchen table gunsmith. I always use my tool with

caution and respect. I also purchased a flexible shaft

for my rotary tool, which allows me to have more control. High

Speed Rotary Tool with Flexible Shaft - I have found a

high-speed rotary tool is invaluable for working on

firearms. However, many professional gunsmiths call the

rotary tool their best friend for bringing them

business. These tools rotate at speeds of 25,000 RPM or

more and can easily damage a firearm beyond the capabilities

of the kitchen table gunsmith. I always use my tool with

caution and respect. I also purchased a flexible shaft

for my rotary tool, which allows me to have more control.

Trigger Pull Gauge - A trigger pull gauge measures the

weight of trigger pull. This tool helps me to determine

how effective my trigger work is. I measure the pull

weight both before and after I perform action work. This

simple gauge shown on the right is available from Midway USA

and is very inexpensive.

Headspace

Gauges - When I purchase a used pistol or rifle I usually

purchase headspace gauges for safety reasons. Headspace

gauges come in three sizes; Go, No-Go, and Field. If the

go gauge chambers properly the chamber is long enough.

If not, I know the chamber is too short and needs to be

reamed. If the no-go gauge won't chamber then the

chamber is ok. If the no-go gauge chambers, the chamber

is too long and unsafe, probably stretched, so I'll have to

shorten the chamber by removing metal off the rear of the

barrel. The use of the field gauge is debated by professional

gunsmiths. Some say if the bolt closes on a field gauge,

don't use the rifle. Some say use the rifle. I

don't use field gauges at all. If the chamber is between

the go and no-go gauges, for me the chamber is safe.

When using these gauges, especially on a semi-automatic

firearm, I remove all springs and extractors. I always

test with light finger pressure only. Using springs or

excessive pressure can damage the gauges. Headspace

Gauges - When I purchase a used pistol or rifle I usually

purchase headspace gauges for safety reasons. Headspace

gauges come in three sizes; Go, No-Go, and Field. If the

go gauge chambers properly the chamber is long enough.

If not, I know the chamber is too short and needs to be

reamed. If the no-go gauge won't chamber then the

chamber is ok. If the no-go gauge chambers, the chamber

is too long and unsafe, probably stretched, so I'll have to

shorten the chamber by removing metal off the rear of the

barrel. The use of the field gauge is debated by professional

gunsmiths. Some say if the bolt closes on a field gauge,

don't use the rifle. Some say use the rifle. I

don't use field gauges at all. If the chamber is between

the go and no-go gauges, for me the chamber is safe.

When using these gauges, especially on a semi-automatic

firearm, I remove all springs and extractors. I always

test with light finger pressure only. Using springs or

excessive pressure can damage the gauges.

Wet/Dry Sand Paper, Various Grits - For polishing small

parts I use black wet/dry sand paper in various grits. I

normally keep 320/400 and 600 grit handy at all

times.

Tap

and Die Set - A good quality tap and die set is another

tool that is good to have. Taps allow me to thread holes

to receive screws, and dies allow me to thread rod to make my

own screws. I also purchased firearm-specific taps from

Brownells which have finer threads for use with gunsmith

screws. Tap

and Die Set - A good quality tap and die set is another

tool that is good to have. Taps allow me to thread holes

to receive screws, and dies allow me to thread rod to make my

own screws. I also purchased firearm-specific taps from

Brownells which have finer threads for use with gunsmith

screws.

Air Compressor - I use a small air compressor to clean

off parts after I have performed filing or grinding. The

forced air helps to get grit and particles out of hard to

reach places. I also use my air compressor with an air

brush to coat firearms with paint-on finishes.

Cold Blue - I use cold bluing solution to protect small

areas of parts I have worked on, or to completely refinish

parts. I use Oxpho-Blue from Brownells for coating

exposed metal on parts on which I have worked, and I use Van's

Instant Gun Blue to totally refinish parts.

Parts Bins/Organizers - I use plastic multi-drawer

organizers for parts and tools. Being somewhat of a

pack-rat, I keep everything, even if it is damaged.

You'd be surprised how many times I've used a leftover part or

spring to fix something else.

My

wife and I love Chinese food; in fact we eat at our local

Chinese restaurant at least once a week. When we order

take out my restaurant has started to use plastic tubs, which

work great for holding chemicals and parts. And because

they come with a lid, I don't have to worry about spilling the

chemicals or losing the parts. Library

- My gunsmithing books are just as important as my other

tools. I refer to them regularly for disassembly

instructions. They also provide me with tips for

performing general gunsmith work, and how to work on specific

firearms. My most valuable books in my library are The

Official NRA Guide to Firearms Assembly Two Volume Set. These

books provide exploded diagrams and step-by-step disassembly

instructions for many firearms. Advanced

Tools - I have a number of what I call advanced tools for

working on firearms. The tool that took me from

performing amateur work to semi-professional work was my

mill/drill. I purchased mine from Harbor Freight Tools,

but if I had to do it over, I would purchase the Grizzly G8689

Mini Milling Machine. This tool has a tilting head which

makes angle cuts very easy.

|