Installing

a Half-Cock Hammer in an Old Model Ruger® Vaquero®

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

It’s probably been over seven years since I’ve

participated in a Cowboy

Action Shooting™ match.

Being laid-off from work and gaining enough weight that

my outfits and leather no longer fit certainly had something

to do with it. I

also lost my long-time shooting partners; one moved 100 miles

away, another one only shoots IPSC now, and the third had some

serious financial setbacks that caused him to have to sell all

of his guns!

Well,

I’ve been gainfully employed for over five years now, I’m

starting to lose weight, and my friend who moved away, Lone

Star, is now retired and wants to start cowboy shooting again.

(If only the price of gas would come down!)

So it’s time to dust off the ol’ shootin’ irons

and get back into the game.

I have two

stainless steel old-model, large-frame Ruger Vaqueros in .45

Long Colt with 5 1/2“ barrels that I decided to modify as

follows to make them more cowboy match friendly:

- Install

a free-spin pawl – this allows the cylinder to rotate

freely forward or backward which makes loading and

reloading quick and easy.

- Install

a half-cock hammer – this allows the chambers in the

cylinder to align properly with the loading gate, allows

recovery from the dreaded skipped round if the hammer

misses the full cock position, and gives the cool extra click when cocking the

hammer similar to a Colt single-action revolver.

These

“improvements” required installing one new part, the

half-cock hammer, and modifying three factory parts, pawl,

trigger, and transfer bar, in order to function correctly

The

Dreaded Skipped Round

The dreaded skipped round is caused by the following sequence

of events:

- The

shooter cocks the hammer with the off hand.

- When

the gun fires recoil causes the “plow-share” grip to

rotate in the shooting hand.

The heavier the load, the more pronounced is the

rotation.

- Eventually

the gun rotates enough so the web of the shooting hand

prevents the hammer from locking back into the fully

cocked position. However,

the cylinder has already rotated so the next live round is

in firing position.

- The

cocking thumb releases the hammer, but because it did not

lock back into the fully cocked position it moves forward

with not quite enough force to fire the round.

Because the hammer falls completely forward it

resets the action.

- The

shooter repositions the shooting hand so the hammer can be

fully cocked. Because

the action was reset by the slipped hammer, cocking the

hammer rotates the live round that did not get fired out

of position and the next live round moves into firing

position. The

shooter just skipped a round.

- The

shooter now has to cycle the action five times to find and

fire the missed round causing a delay “on the clock”.

I

eliminated this problem by training myself to hold the gun

with my little finger hanging below the grip.

This prevented the gun from rotating in my hand under

recoil and avoided the skipped round problem. Installing

a hammer with a half-cock notch would not eliminate this

problem, but it would prevent skipping a round because if the

hammer slipped it would fall on the half-cock notch instead of

completely forward so the action would not be reset.

If I cocked the hammer again it would not bypass the

live round. By the

way, this only works if I don’t keep the trigger pressed,

which I don’t.

Speaking

with the Grand Master Himself

When the new hammers arrived I found they were incorrectly

packaged with instructions for a Ruger 10/22 trigger guard so

I called Power Custom Inc. to see if I could get the correct

instructions faxed or emailed out to me.

I called on a Saturday and lo and behold, I spoke with

Ron Power himself. I

already knew what had to be done for modifications, but Ron

gave me some additional tips:

- Be

sure to mill the top of the trigger sear engagement

surface, not

the bottom. Also

be sure the trigger fits into the half-cock notch or it

will break off the front of the notch.

- Lengthen

the notch in the transfer bar by 0.090 – 0.100”, I

chose the middle of 0.095”.

He said to use a file, but that a carbide mill

would work.

- Once

the gun is reassembled make sure I can fully cock the gun

for all six chambers using a gentle pull of the hammer.

If not, I would need to shorten the bottom tooth of

the pawl until I could perform this.

His suggestion for filing this tooth was to remove

the cylinder, cock the gun so the pawl is protruding into

the frame, then place a punch behind the pawl to hold it

in place.

- His

last suggestion was to ensure the hammer plunger slipped

off of the cylinder latch with the hammer about 1/8“ away from the

frame. Adjust

this by filing the rear of the cylinder latch.

Complete

Disassembly and Cleaning

Before beginning this project I made sure my revolvers were

unloaded and completely disassembled each gun.

Refer to my article Ruger®

Single-Action Revolver Disassembly/Reassembly and Spring

Replacement. I

did one revolver at a time so I wouldn’t get the parts mixed

up. I used Q-tips

and cleaning solvent to get soot out of all the nooks and

crannies inside the frame.

You’d be amazed how much soot gets into the internals

of the revolver! I

shoot light loads which don’t allow the brass cartridge case

to expand to completely seal the chamber which causes some

blowback of burning gasses.

When I decided not to shoot cowboy matches for awhile I

disassembled and thoroughly cleaned each revolver before

putting it away, so my revolvers were already clean, but it

doesn’t hurt to go over everything again.

Making

a Free Spin Pawl

The pawl is

the small arm that is connected to the hammer and has two

teeth; one at the top and one in the middle.

The pawl is held against the cylinder ratchet by the

pawl spring and plunger. When

the loading gate is open the top tooth of the pawl allows the

cylinder to rotate in only one direction.

When the cylinder is rotated clockwise the top tooth

slips over each tooth of the cylinder ratchet giving the

audible click.

If the

cylinder is rotated counter-clockwise a tooth of the cylinder

ratchet presses against the top tooth of the pawl and prevents

the cylinder from rotating backwards any farther.

Unfortunately, with the old-model Vaquero, when the

cylinder is stopped against the pawl a chamber is not properly

aligned with the loading gate for loading and unloading as you

can see in the above figure.

As the

hammer is pulled to the rear the cylinder latch (other

manufacturers call this the bolt) drops down into the frame

thereby unlocking the cylinder and allowing it to rotate. The

cylinder latch is the flat, half-round piece of metal that

protrudes from the inside bottom of the frame.

It mates with a notch cut into the cylinder and

prevents the cylinder from rotating when the gun is fired.

The top tooth of the pawl engages a tooth on the

cylinder ratchet and causes the cylinder to start to rotate.

When the cylinder begins to rotate the cylinder latch

moves back into the raised position and drags against the

cylinder causing what some consider to be the unsightly

“drag ring” on the cylinder.

As the cylinder rotates the bottom tooth of the pawl

engages the next tooth on the ratchet and allows the cylinder

to continue rotation until the cylinder latch locks the

cylinder in place. The

teeth on the pawl control the timing of the cylinder and are

fitted at the factory.

Before

modifying the factory pawls on my two Vaqueros I wanted to

test to make sure the half-cock hammer would function with the

modified pawl. I

have a Ruger Bisley Blackhawk® that has my modified free-spin

pawl. With the

loading gate closed (you can’t cock the hammer if the

loading gate is open) I pulled the hammer back just enough so

the cylinder latch dropped down into the frame thereby

unlocking the cylinder. With

the hammer partially pulled back and the cylinder latch in the

down position I was able to rotate the cylinder in only one

direction as indicated by the audible clicks of the hand

slipping over the ratchet.

When I rotated the cylinder backwards against the pawl

I noticed that a chamber was properly aligned with the loading

gate as it would be if the half-cock hammer was installed.

Ok, because this functioned properly I can modify my

factory pawls.

After

further analysis I determined that the modified pawl had to

function correctly or the gun wouldn’t cycle!

The modified pawl does not contact the cylinder ratchet

when the hammer is down, but it still has to contact the

ratchet to start the cylinder rotating during the cocking

cycle; refer to the above figure.

I marked

the top of the pawl with a blue marker and with the hammer

down and loading gate open, rotated the cylinder

counter-clockwise a few times until it was stopped by the

pawl. This left a

mark on the top of the pawl which told me how much metal to

remove.

By filing

the top tooth at an angle it no longer contacted the cylinder

ratchet and allowed the cylinder to rotate freely in either

direction. I made

sure I removed just enough metal so the cylinder ratchet no

longer made contact with the pawl.

If I removed too much metal the cylinder may not

rotate, and/or may not contact the ratchet with the new hammer

in the half-cock position.

Because I left about 1/16” it still functioned

correctly when the hammer was cocked.

Refer to my article Making a Free Spin

Pawl for a Ruger® Single-Action Revolver.

I have successfully performed this modification to a

number of Ruger single-action revolvers.

Once I

installed the half-cock hammer, with the hammer in the

half-cock position, the free spin pawl was raised just enough

so that if I moved the cylinder backwards, it caught on the

top tooth of the pawl with a chamber properly aligned with the

loading gate as seen in the above figure.

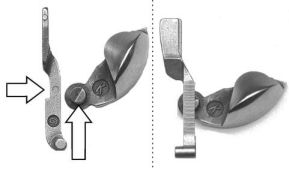

Modifying

the Trigger

Power Custom sells the entire drop-in half-cock hammer kit

that includes the half-cock hammer, modified trigger, and

Wolff spring kit. This

kit is available from MidwayUSA as product # 345935.

Both of my Vaqueros already had a Wolff spring kit

installed, and I knew I could successfully modify the trigger

myself with my mill, so I decided just to purchase the

half-cock hammer from MidwayUSA product # 439111.

MidwayUSA doesn’t stock this part so they

special-ordered it for me.

This not only saved me some money, but gave me some

additional gunsmithing work to perform.

The factory

trigger comes with a very large sear engagement surface; too

large to fit into the half-cock notch of the new hammer.

The half-cock notch measured a little over 0.050” so

I would need to leave that much or a little less.

I not only needed to remove the top of the engagement

surface, but I also needed to grind a little metal off of the

bottom to allow the trigger to fit around the curve of the new

hammer and seat into the half-cock notch as shown in the above

figure.

I placed

the trigger in my milling vise at the proper angle and used a

1/4” square end bit to remove the metal.

I could have used a file to remove the metal, but the

milling machine insured my work was flat and square.

Then I took a small grinding stone and my high-speed

rotary tool and ground a slight radius on the bottom; just

enough so the trigger would fit into the half-cock notch.

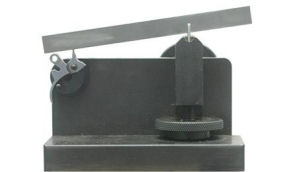

The Power

Custom Series 1 Stoning Fixture that I purchased from

MidwayUSA product # 743549

has two holes in the top where I can set the hammer and

trigger pins and see the relationship of the hammer to the

trigger. This is

how I discovered that I needed to grind a radius in the bottom

of the trigger. Notice

the inset in the above figure; the trigger is blocked from

seating completely into the half-cock notch by the rounded

shape of the full-cock notch.

By grinding a radius in the trigger where the hammer is

touching the trigger will seat fully into the half-cock notch.

After I

finished milling and grinding I removed any burrs and polished

the surfaces. I

then installed the RSA adaptor I purchased from MidwayUSA

product #765339

into my Power Custom Series 1 Stoning Fixture and honed the

sear engagement surface. I

used ceramic sticks to polish the engagement surface that I

purchased from Brownells,

stock #080-721-621WB,

the black one for coarse polishing, and the white one for

final polishing. Ceramic

stones use water as the cutting agent, not oil.

I marked the engagement surface with a blue marker to

ensure I was polishing it square and flat.

Modifying

the Transfer Bar

The

transfer bar is a safety feature of the Ruger single-action

revolvers which allows the gun to be carried safely with all

six chambers loaded. With

the hammer down, the transfer bar sits down out of the way of

the hammer and firing pin.

When the hammer is cocked the trigger moves to the rear

lifting the transfer bar up to cover the firing pin.

When the trigger is pulled to the rear the transfer bar

stays in the up position, the hammer falls striking the

transfer bar which transfers the hammer’s energy to the

firing pin and ignites the primer of the loaded cartridge.

The

transfer bar has a notch cut into it.

When the loading gate is open the half-round protrusion

at the end of the pivot pin rotates into that notch and blocks

the transfer bar which prevents the hammer from being cocked.

This defeats the purpose of the half-cock hammer!

I followed Ron Power's instructions to modify the

transfer bar to increase the length of the notch.

Now the hammer would not be blocked and could be placed

in the half-cock position with the loading gate open.

Following

Ron’s suggestions I marked the factory transfer bar with a

blue marker, set my calipers to 0.095” as shown in the above

figure, then scored the transfer bar to show where I needed to

mill.

I put the

transfer bar into my milling vise and used a 3/32” ball-end

bit to remove the metal. The

ball-end bit left a radiused corner at the base of the cut

which should prevent cracking.

A square-end bit would leave a sharp corner which could

crack over time.

Installing

the Half-Cock Hammer

Installing

the new half-cock hammer was a simple matter of replacing the

factory hammer, and reassembling the gun.

I made sure everything was properly lubricated before

reassembly.

First I

tested the free-spin pawl by opening the loading gate and

spinning the cylinder in both directions.

Then I closed the loading gate and fully cocked the

hammer. The extra

click I heard as the trigger passed over the half-cock notch

did sound pretty cool! I

measured trigger pull at 2 1/2 pounds, and let off was crisp

and clean with no creep or drag.

All 6

chambers locked up, but the hammer was a bit tight.

I wanted just a little bit of play, so again following

Ron’s directions, I removed a few thousandths from the

bottom tooth until there was just a small amount of forward

and backward play in the hammer when fully cocked.

Next I

pulled the hammer back into the half-cock position and opened

the loading gate. I

rotated the cylinder forward (clockwise) and heard the

familiar clicks as the cylinder ratchet moved over the top

tooth of the pawl. I

moved the cylinder backwards (counter-clockwise) until it

stopped and sure enough a chamber was aligned with the loading

notch in the frame.

Finally, I

wanted to simulate the dreaded skipped round.

With my shooting hand held high on the grip and my

finger off the trigger I pulled the hammer back until it hit

the web of my hand and wouldn’t go any farther.

I let the hammer slip off my thumb and the half-cock

notch caught it, but since the hammer didn’t completely

fall, the action didn’t reset.

I was able to re-cock the hammer and the cylinder did

not rotate so I didn’t bypass the chamber.

Even though I grip the gun with my little finger below

the grip, it’s nice to have this feature as a backup.

Accurizing

While I had both revolvers apart I slugged the barrel and

measured the chamber throats in the cylinders.

Both revolvers suffered from the typical Ruger big-bore

problems:

- The

barrels slugged 0.451” but each had a constriction under

the barrel threads

- The

chamber throats measured 0.4495” – 0.450”

Essentially

I would have had a 0.452” bullet swaged down to 0.450” or

less depending on the amount of barrel constriction, wobbling

down a 0.451” barrel; not exactly a great recipe for

accuracy! I opened

up the chamber throats to 0.452” and removed the

constriction by hand-lapping the barrel.

Refer to my article Accurizing

the Ruger® Single-Action Revolver.

Summary

So now the question is; which method do I use to load and

unload the revolver? I

put the hammer in the half-cock position for normal loading

and unloading. I

do the Colt loading sequence of load one chamber, skip one

chamber, and then load the other four.

After loading the fifth round I close the loading gate,

pull the hammer all the way back, then carefully drop the

hammer over the empty chamber.

When

loading under the clock I open the loading gate allowing the

cylinder to free spin, load one round, rotate the cylinder

counter-clockwise 2 chamber positions, then close the loading

gate. When I cock

the hammer the loaded round moves into the firing position.

So why

didn’t I just mill a half-cock notch into the existing

hammer? There is

not enough metal on the front of the factory hammer to mill

out the notch. I

would either have had to add metal to the front of the hammer

and then mill the notch, or purchase a new hammer which was

the better solution for me.

A special

thanks to Ron Power for his suggestions to ensure my

installation of his half-cock hammers went smoothly.

Thanks to him both of my Vaqueros are ready for competition.

|