Building

a Dedicated 1911 .22LR Pistol

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Index

Introduction

Purchasing the Receiver

Purchasing Parts and Tools

Parts List

Tool List

Polishing the Frame

Frame Top

Dust Cover

Trigger Guard

Magazine Well

Fitting Beaver-Tail Grip Safety to Frame

Blending Frame and Grip Safety

Fitting the Mainspring Housing

Checking for Protrusions in the Magazine Well

Polishing Barrel

Bed and Feed Ramp

Performing

Additional Polishing

Installing the

Plunger Tube

Installing Fire

Control System

Preparing and

Installing Fire Control Parts

Fitting Thumb

Safety

Fitting Grip

Safety to Trigger

Adjusting

Trigger Pre/Over Travel

Polishing Fire

Control Parts

Performing

Function and Safety Checks

Cleaning Up and

Installing Small Parts

Bead Blasting

Bluing Parts

Lubricating and

Assembling All Parts

Test Firing

Custom Grips ___________________________________________________________________

Introduction

I

have a number of 1911’s in my collection; all of them I

built from scratch with hand-fitted parts.

Two of them are single-stack in .45 ACP, and one is a

double-stack, wide-body in 9mm.

I also have an Advantage

Arms .22LR target conversion kit model 1911-22T that I

sometimes use on one of my 1911 .45 ACP frames.

The .22 conversion kit is an economical and fun means

to practice with a 1911, especially with the current cost and

lack of availability of .45 ACP ammo.

I chose this conversion kit because it was the target

model, and the slide locked back after the last round.

Some other conversion kits on the market do not offer

the slide lock feature. As

a plus the unit came with a cleaning kit and a nice carry

case. Rather than

having to swap the conversion kit onto a .45 frame, I decided

to build a dedicated 1911 .22.

Just in case you’re wondering, it is always more

expensive to build a gun from parts than to purchase a

complete gun, but where is the fun in purchasing when you can

build!

Purchasing

the Receiver

I

purchased a standard carbon-steel frame with a custom serial

number from Caspian Arms.

Caspian Arms offers many extras on their frames, such

as checkered front strap, integral plunger tube, integral

accessory rail, wide magazine well, and many others.

I did not order any extras except the custom serial

number. The custom

serial number I chose was KTGS 22 for “Kitchen Table Gun

Smith 22”. Because

the receiver was serialized I had to have it shipped to my FFL

dealer. Walt at

Caspian Arms indicated that they had about an 8-week backlog

of orders; which worked out fine for me because it gave me

time to purchase the additional parts to populate the

receiver.

True

to Walt’s estimate, the frame arrived at my FFL dealer two

months after ordering. After

filling out the paperwork and paying the transfer fee I

finally had the frame in my hands.

It is pretty much a standard GI 1911 frame, but ya

gotta love that custom serial number!

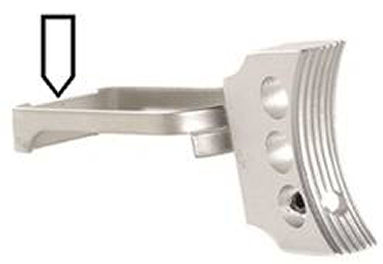

Notice the long, pointed “tails” on the rear of the

receiver where the standard GI grip safety fits.

These tails will be filed off and rounded to fit a

beaver-tail grip safety.

Purchasing

Parts and Tools

Below

is a list of parts and tools I purchased to build KTGS 22.

Most of the parts I found at Midway USA on sale.

Where possible I included the part number, but not the

price since prices change frequently.

This was my fourth 1911 build so I already had the

tools on hand, but they can be purchased from Midway USA or

from Brownells. Polishing

sticks I made from wooden dowels and 1/4“ flat wood stock

with 400 grit paper. I

wrapped the paper around the dowels, and glued the paper to

the flat stock.

Parts

List

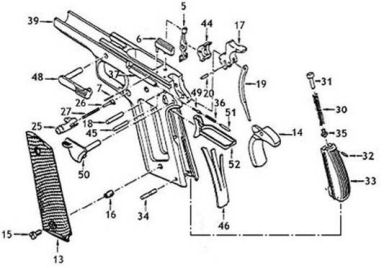

|

Drawing

Reference Number

|

Source

|

Part

No.

|

Description

|

|

4,

7, 18, 20, 31, 32, 34, 35, 45, 49, 51

|

www.midwayusa.com

|

572-340

|

Swenson

pin set

|

|

5

|

www.midwayusa.com

|

111-344

|

Smith

& Wesson disconnector

|

|

6

|

www.midwayusa.com

|

923-179

|

Ed

Brown Ejector

|

|

10,

27,30, 36, 41, 46

|

www.midwayusa.com

|

115-123

|

Wolff

.45 Government Spring Pack

|

|

13

|

Homemade

|

N/A

|

Grip

Panel

|

|

14

|

www.midwayusa.com

|

181-642

|

Ed

Brown speed bump beaver-tail grip safety

|

|

15

|

www.midwayusa.com

|

172-684

|

Slotted

Grip Screws (4)

|

|

16

|

www.midwayusa.com

|

734-065

|

Grip

screw bushing (4)

|

|

17

|

www.midwayusa.com

|

532-745

|

Smith

& Wesson hammer

|

|

19

|

www.midwayusa.com

|

659-211

|

Smith

& Wesson hammer strut

|

|

25

|

www.midwayusa.com

|

413-295

|

Nighthawk

extended checkered magazine catch

|

|

26

|

www.midwayusa.com

|

652-512

|

Wilson

Magazine Release Lock

|

|

30

|

www.midwayusa.com

|

237-409

|

Wilson

19lb mainspring

|

|

33

|

www.midwayusa.com

|

260-701

|

Kimber

flat checkered mainspring housing, polymer

|

|

37

|

www.midwayusa.com

|

358-241

|

Swenson

Plunger tube

|

|

44

|

www.midwayusa.com

|

125-678

|

Nowlin

sear

|

|

48

|

N/A

|

N/A

|

Slide

stop - Came with the conversion kit

|

|

50

|

www.midwayusa.com

|

215-306

|

Swenson

extended thumb safety

|

|

52

|

www.midwayusa.com

|

623-353

|

Nowlin

ultra-light trigger

|

As

you can see from the list, the result is a “Franken-pistol

mix-master” of parts. However,

everything was hand-fitted so they all fit and worked

harmoniously together.

Tool

List

Below

are the special tools I used to build KTGS 22.

Polishing

the Frame

A

gun should look as good as it shoots.

The more time and care I apply here will benefit in the

finished product. There

were several places I needed to address, but I started with

the top of the frame. I

put the frame in my vise with the top up and used the magazine

well filler to make sure I didn’t apply too much pressure.

The magazine well filler prevented me from crushing the

delicate frame. The

vise jaws were padded with leather so as not to mar the frame.

Frame

Top

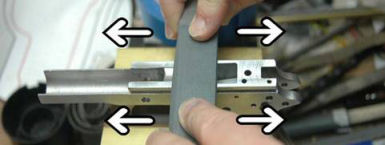

The

top of the frame had some tool marks which I wanted to remove

and polish. I

wrapped a piece of 400-grit paper around a bastard file and

polished the top until there were no more tool marks.

I needed to be careful to keep the file very flat as I

didn’t want to “bow” or round this top surface.

I used a “draw-filing” action where I laid the file

at right angles to the frame and moved the file parallel with

the frame (refer to the photo above).

After the tool marks were gone I finished polishing

with 600-grit paper.

Dust

Cover

A Dremel® tool is one of my favorite tools because of its

versatility, and it’s great for working on guns.

Because the Dremel® tool spins at up to 25,000 RPM or

more it can run away and cause some serious damage.

This tool has to be treated with respect.

When I have it turned on, it will do the work that I

desire, but if I don't pay close attention it could get away

from me. A

professional gunsmith once commented that the Dremel® tool

was his best friend because it generated a lot of business for

him!

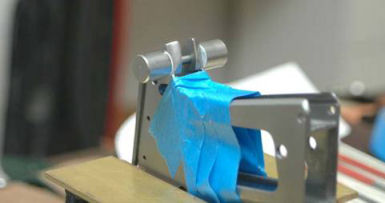

I

put a 1/2“ fine sanding drum on a Dremel® flex shaft.

I put 3 layers of blue tape around the chuck to prevent

scoring the dust cover while polishing.

I clamped the frame in the vise with the dust cover

level and facing me. I

turned the tool to speed setting #4, and while holding it in

both hands, smoothed the inside of the dust cover by moving

the tool back and forth until it was nice and shiny.

Too much pressure on the drum could cause gouges so I

just let the drum kiss the metal.

This

is plenty smooth for the inside of the dust cover, but I

wanted it really polished so I continued to polish with

400-grit paper wrapped around the sanding drum, then I

finished with 600-grit paper wrapped around the sanding drum

to perform the final polish.

Now

I needed to work on several more areas of the frame.

I’m using small tools and working gently.

I’ve already polished the inside of the dust cover so

now I needed to smooth out the upper edges and remove the

sharp corners.

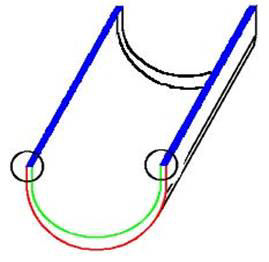

First

I took a jeweler’s file and carefully beveled the inside

edge of the end of the dust cover (green edge).

After beveling with the file I used my Dremel® tool

and a Cratex® tip to finish polishing this area.

I didn’t want to change any dimensions, just make it

smooth.

The

upper part of the dust cover should be flat and smooth (area

in blue). I used

400-grit paper wrapped around my bastard file to draw-file

these edges.

The

two sharp corners at the top end of the dust cover should be

relieved so they are no longer sharp (circled corners).

Again I used a jeweler’s file to round the corners,

then polished with a Cratex® tip.

As

part of the carry bevel I’m going to bevel the bottom front

edge of the dust cover (red edge).

The carry bevel prevents sharp edges from tearing up a

holster and my hand. I’ll

do more later, but for now I used a jeweler’s file and

Cratex® tip to smooth this edge as I did before.

Trigger

Guard

The

inside and outside edges of the trigger guard were also sharp.

I used a jeweler’s file and Cratex® tip to smooth

these edges as I did before.

The

under side of the frame inside of the trigger guard, and the

inside of the trigger guard itself had some deep tool marks

that I wanted to remove. I

took strips of 400-grit sand paper and polished these areas

using a back-and-forth “shoe shine” motion.

I replaced the paper strips frequently, and continued

polishing in this manner until the tool marks were removed.

Magazine

Well

The

magazine well has some sharp edges that I needed to address

with files and Cratex® bits.

I beveled and polished the outside edges of the

magazine well, and the inside edges ONLY where the magazine

fits. I did not

bevel and polish any of the inside edges where the mainspring

housing sits. I

also beveled and polished the outside and inside edges of the

round front strap.

Fitting

Beaver-Tail Grip Safety to Frame

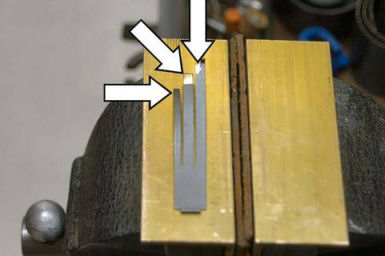

This

has always been a fun process for me and when done right it

looks very clean and professional.

First I taped my frame along the back edge where the

grip safety goes to avoid nicking with the file.

Then I put the frame in my vise and installed the Ed

Brown grip safety jig.

With

a bastard file I started taking the metal away from the two

“tails” of the frame making sure I removed the same amount

on each side. I

put chalk on the file to keep the teeth from getting full, and

moved the file in one direction only.

After about 20 strokes I used a brass brush to clean

the file and re-chalked.

When

I got close to the hardened steel “rollers” on the jig I

switched to a Barrette file to remove more metal.

I took it right down to the rollers.

The rollers are made of hardened steel so the file

wouldn’t cut into them.

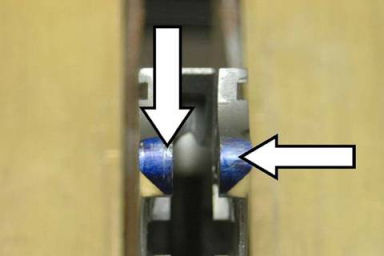

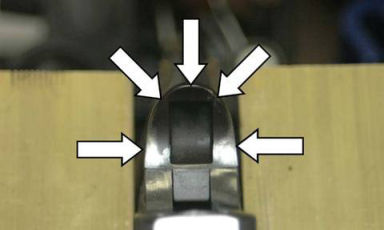

The above

photo shows the tails filed down to the jig.

Now

that I’ve cut the proper radius I needed to fit the grip

safety. I used a

blue marker to mark the radius on the frame that I just filed,

then installed the safety with a taper pin.

I used a soft-faced mallet to tap the taper pin in

fairly snug.

I

rotated the safety, then removed the taper pin and safety to

see any white marks that indicated I needed to remove a bit

more metal. I took

a jewelers file to gently remove a small amount of metal where

the white marks indicated.

I re-marked the radii and re-installed the safety with

the taper pin and continued to check for high spots until no

blue wore off.

Blending

Frame and Grip Safety

When performing the frame/grip safety blending I always wear a dust

mask and safety glasses because there’s quite a bit of metal

dust in the air which I don’t want to get into my nose,

lungs, or eyes.

I installed the grip safety onto the frame with a hammer pin, then

taped the grip safety down so the gun would be smooth when

being held.

Then I

took my Dremel® tool with a

1/4“ fine sanding drum and blended the frame with the bottom

of the grip safety until smooth.

I smoothed everything up by shoe shining with 400-grit

paper, followed with a Cratex® bit.

I

blended the top of the grip safety with the frame in the same

manner. The

objective here is to make a smooth surface for the web of the

thumb, and to make everything look smooth and professionally

fitted.

Fitting

the Mainspring Housing

Although

I purchased a polymer flat mainspring housing (MSH), I really

didn’t like the feel of the polymer.

I had a blue steel flat mainspring housing in my parts

bin which I decided to use.

I wanted the mainspring housing to fit just as cleanly

as I did the rest of the gun.

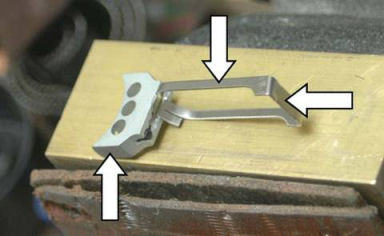

First I assembled the mainspring housing and parts as

illustrated above. I

installed the cap and plunger onto the mainspring, installed

them into the housing, put the housing in my vise and used a

punch to push the plunger into the housing so I could install

the retaining pin. I

wore safety glasses in case the punch slipped.

There is nothing worse than having springs and

small parts fly off to who knows where and trying to find them

in a crowded gun room. I

think they go to the same place as odd socks!

I assembled the sear spring and mainspring housing in the frame.

I put 3 layers of tape over the bottom of the magazine

well, and then took my bastard file and draw-filed the bottom of the MSH

until it was flat with the frame.

I then polished the bottom of the frame and MSH with a

400-grit paper wrapped around a bastard file.

The rear corners of the frame were beveled but didn’t match the

MSH. I put a fine

sanding drum on the Dremel® and beveled the corners of the

frame to match the MSH, then polished out the tool marks with

a Cratex® bit.

I had used this flat mainspring housing to practice checkering, but

buggered it up. I

used my bastard file to draw-file off the checkering, then

shoe-shined it with 400-grit paper.

Since a .22 LR doesn’t recoil very much I don’t

really need any checkering to keep the gun in my hand.

Checking

for Protrusions in the Magazine Well

Sometimes new grip screw bushings protrude into the magazine well

so I wanted to make sure they set flush and wouldn’t drag on

the magazine. First

I removed the main spring housing and sear spring.

I discovered that the grip screw bushings did not screw easily into

the frame. I

chased the threads with a .236” – 60 grip screw bushing

tap to make sure the threads were clean, then I installed the

grip screw bushings in the frame, being careful not to

cross-thread them, and made them fairly tight.

Using my bastard file I smoothed the inside sides of the magazine

well where the bushings might be slightly sticking up.

On this particular frame the bushings protruded on only

one side. I left

the bushings installed for the rest of my work.

Since some of the bushings were now of different

lengths I needed to make sure they went back in the same

locations when I removed them in preparation for final

finishing. After I

removed each bushing I put a piece of tape around it and

labeled its location so I would know where to put them when I

re-assembled the gun.

I re-installed the sear spring and mainspring housing and checked

to see if the sear spring tab was protruding through the slot

into the magazine well. Mine

wasn’t, but if it was I would have used a #0 pillar file to

smooth the tab flush.

Polishing

Barrel Bed and Feed Ramp

I now wanted to make the barrel bed ready to accept a

barrel. This

process isn’t necessary for my .22 top end, but I wanted

this frame to be able to accept a .45 top end as well.

Performing

Additional Polishing

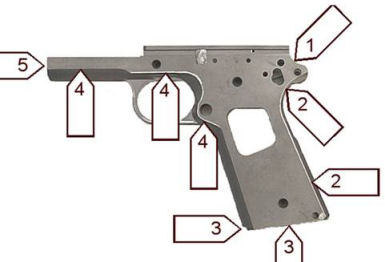

Now

I did some additional work on the frame.

Sharp edges I beveled with a jewelers file and polished

with a Cratex® tip. Wherever

I had a frame line, not an edge, I used just a Cratex® tip to

make that line a bit softer, but did not eliminate it.

Refer to the above photograph for references to the

numbered areas described below.

1.

First

I beveled the sharp outside edge at the rear of the frame

between the slide and the grip safety with a file then Cratex®

bits. This edge

was left very sharp after I blended the grip safety with the

frame.

2.

Next

I worked on the edges of the rear of the frame where the grip

safety and mainspring housing set.

3.

I

then beveled the outside of the magazine well including the

front round edge.

4.

I

slightly softened all frame lines with a Cratex® bit, but I

was careful not to do too much.

5.

Finally

I beveled the outside edge of the dust cover.

I did this previously but I just wanted to make sure I

got the sides as well.

I

took a careful look at the frame just to see if there were any

other areas that needed work.

I decided to run a Cratex® bit over the top edge of

the grip safety because that edge felt a bit sharp.

Installing

the Plunger Tube

The

plunger tube is probably the most fragile part of the 1911.

I’ve had to install three plunger tubes on another

gun I built because of my own stupidity.

But, this is how we learn.

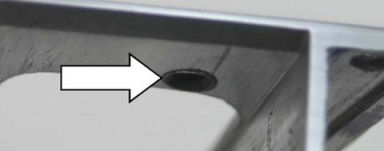

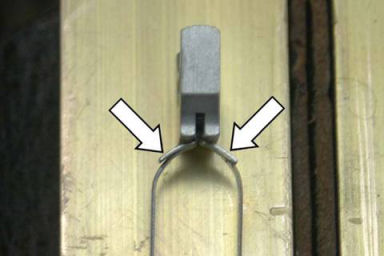

Before I could install the plunger tube I needed to

chamfer the holes where the tube attaches to the frame.

I

chucked a 1/8” carbide ball cutter into a keyless chuck,

which I then inserted into my gunsmith screwdriver.

I put the ball end against the hole on the inside of

the frame and rested the shank on a piece of leather and

turned it until I had a nice chamfer.

This chamfer will help hold the plunger tube tightly

against the frame. The

leather is not shown in the above photo for clarity.

The leather prevented me from marring the frame.

I

cleaned off all the shavings, then cleaned the area with

Acetone using a Q-Tip. I

also cleaned the back of the plunger tube with Acetone.

Now

that everything was clean I put a thin bead of green Loctite

609 in the area where the plunger tube will be and made sure I

got some in the holes. I

also put some on the back of the plunger tube itself.

I

inserted the tube into the holes and made sure the small hole

was to the front, and the large hole was to the rear.

I cleaned away the excess Loctite with a Q-tip and

acetone, then put the frame in my vise.

I applied just enough pressure to keep the plunger tube

in place. I let it

set for 24 hours to give time for the Loctite to set up.

After

the Loctite had time to set up, I expanded the stud/rivets

with a plunger tube staking tool.

In

the process of cutting the chamfer with the ball end I raised

a burr around the two holes.

I took my 400-grit polishing stick and polished off the

burr so again, the inside of the magazine well was nice and

smooth for the magazine.

Installing

Fire Control System

Now

I was ready to install the fire control system.

The first part to go in was the trigger, but first I

had to prepare the frame.

The area in which the trigger rides needed to be

smoothed. First I

polished the two trigger stirrup channels, one on each side of

the frame. I used

narrow 400-grit polishing stones until both channels were nice

and smooth.

Then

I polished the four areas up forward where the trigger sticks

out of the frame. Again,

I used my polishing sticks to smooth the top, bottom, and

sides of the trigger cut.

I needed to be careful not to change any dimensions,

only smooth. There

were some burrs here that prevented me from installing the

trigger, but smoothing these surfaces removed the burrs and

the trigger fit perfectly.

Now

that the trigger channel was all smoothed I polished the sides

of the trigger stirrup with a Cratex® bit.

Now I tried the trigger in the frame.

Because it fit perfectly I didn’t have to perform any

additional fitting. If

the trigger had been oversized I would have carefully polished

the top and bottom of the trigger shoe with 400-grit paper

until it just fit.

Next

I assembled the magazine catch with the magazine catch itself,

the magazine catch spring and the magazine catch lock.

After I inserted the spring and lock into the catch I

rotated the lock counter-clockwise until the tab caught in the

slot.

I

inserted the assembly into the frame with my finger holding it

in. I held a

screwdriver in my other hand and rotated the lock until it set

in the groove in the frame.

I worked the magazine catch a few times to feel for any

resistance.

At

this point I carefully inserted an empty magazine to see if it

contacted the trigger stirrup.

The magazine slid in smoothly with no contact.

Preparing

and Installing Fire Control Parts

Now

that the trigger and magazine catch were installed I continued

installing the fire control system.

The parts I needed were:

- The

Sear

- The

Disconnector

- The

Hammer

- The

Hammer Strut

- The

Hammer Strut Pin

- The

Plunger Tube Assembly

- The

Hammer Pin

- The

Sear Pin

First

I smoothed the sides of the hammer and sear by rubbing them on

a flat sheet of 600-grit paper.

Then I rubbed the corners of the sear on a 400-grit

polishing stone to break the corners.

Next

I smoothed all sides of the hammer strut.

First I used a fine polishing stone on my Dremel® tool

set at a slow speed just to remove the high spots and sharp

edges. Then I

finished with a Cratex® bit.

I

laid the hammer on a hard flat surface, lined up the hole in

the hammer with the hole in the strut and tapped the pin in as

pictured above. I

was careful to start the pin straight and get it in all the

way. Once this was

assembled, I stoned both areas where the pin comes through to

make sure that it was smooth.

Now

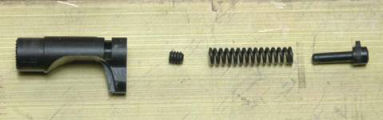

I assembled the plunger tube parts.

The small pin went to the front; the larger pin went to

the rear. Then I

installed the assembly into the plunger tube.

I

took the disconnector and tried to put it in the hole from the

top. Mine fit

perfectly, but if it hadn’t I would have polished the ring

at the top of the disconnector until it would go through the

hole

I

assembled the 'cradle' with the sear and disconnector as shown

in the photo above. I

installed the sear and disconnector into the frame and

installed the sear pin to keep them in place.

I

now installed the hammer with the hammer pin.

Fitting

Thumb Safety

Now

I fit the thumb safety. I’ve

done this on other guns and have had problems with the

thickness of the frame where the safety wouldn’t completely

rotate. I removed

all parts from the frame except for the trigger and magazine

release. First I

made sure the back of the safety was perfectly flat with no

raised casting marks. I

filed away any raised edges with a jeweler’s file.

Note in the photo above how I had to polish off the

raised edge around the outside of the safety.

Then

I installed the thumb safety so that it was flat against the

frame. I moved the

safety up and down to see if it would rotate freely in the

safety cutout slot in the frame.

My safety rotated freely and did not bind on the frame.

Now

that the safety rotated freely, I removed it and re-installed

the sear, disconnector, and sear pin.

Next I installed the sear spring making sure that the

little tab at the bottom of the spring was in the slot in the

frame, and the flat at the top of the left most leaf was

against the bottom of the sear.

I installed the mainspring housing and pinned it in

place with the mainspring housing pin,

then I installed the hammer and hammer pin.

I

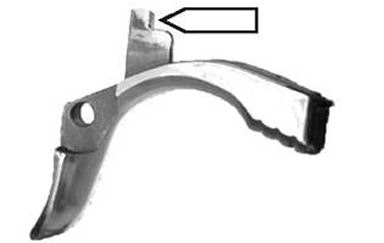

cocked the hammer and tried to install the safety.

It wouldn’t go all the way in because it was hitting

against the sear. I

lightly filed the engagement surface with a file only 2 or 3

strokes at a time until the safety would go in and I could

engage it, making sure it blocked the sear.

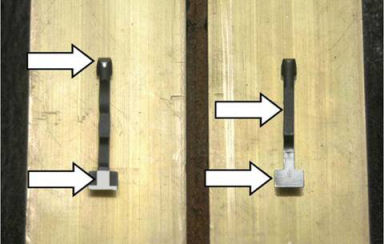

Fitting

Grip Safety to Trigger

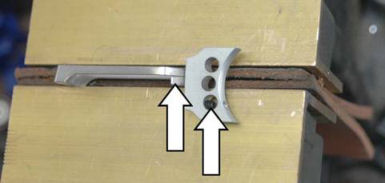

Now

I was ready to fit the beavertail safety to the trigger

stirrup. First I

removed all of the trigger parts except the trigger and the

magazine catch. In

this way I could see how the grip safety engaged the trigger

stirrup. In the

safe position the grip safety prevents the trigger from moving

rearward to disengage the sear.

When I grip the gun the grip safety is depressed and

rotated and the leg on the safety is moved up and out of the

way of the trigger stirrup.

I installed the beavertail safety and the thumb safety

and kept the thumb safety in the lowered or fire position.

I

then installed the mainspring housing and held it in with the

retaining pin half-way in.

By looking inside the frame I could see how the grip

safety contacted the trigger stirrup.

I

removed metal from the bottom of the grip safety leg with a

file until the trigger would slide under it when the grip

safety was depressed. I

then polished the top of the rear of the trigger, and the

surface I just filed with a 400-grit polishing stone to make

them smooth.

Grip

safety out, trigger blocked

Grip safety in, trigger not blocked

Adjusting

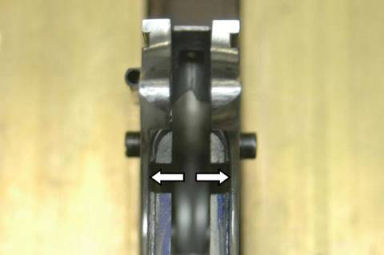

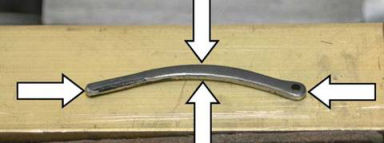

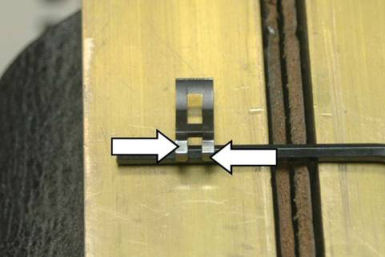

Trigger Pre/Over Travel

I

purchased a trigger with pre-travel adjustment tabs and an

over travel set screw, so now I adjusted pre-travel and over

travel. First I

installed the complete trigger group.

Then I pulled the hammer back and let it rest in the

half cock position.

The

first time I performed the pre-travel adjustment on another

pistol I gripped the trigger shoe to bend out the adjustment

tabs. This caused

the trigger shoe and stirrup to become so misaligned I spent

over one hour getting them realigned.

So now I only grip the stirrup and tab, never the

trigger shoe.

With

the hammer in the half-cock position the trigger should have

no rearward travel at all.

I used two pair of needle-nose pliers to bend the tabs

out by gripping only the stirrup and tab.

I

really didn’t have to bend the tabs very far to take up the

pre-travel. I’ve

done this before and the amount of bend is about the same for

most guns.

Now

for the over-travel adjustment.

I cocked the hammer and turned the adjustment screw in

until the hammer didn’t fall.

Then I backed out the screw 1/2 turn to see how it

worked. I held the

hammer back when I pulled the trigger and gently let the

hammer go forward. I

could feel the half-cock notch on the hammer just touch the

sear so I backed out the adjustment screw another 1/4 turn.

I tested it again just to make sure the half-cock notch

didn’t touch the sear. Once

set I used some Loctite blue to lock the set screw in place.

Polishing

Fire Control Parts

Now

I performed some final polishing on parts of the trigger group

to get a good, reliable trigger pull.

First I polished the front of the two left leaves of

the sear spring. The

left-most leaf contacts the sear and allows the sear to return

to the fire position. The

middle leaf contacts the slanted surface of the disconnector

and allows it to return to the fire position.

The right leaf returns the grip safety to the safe

position. I also

needed to make sure that the two outside leaves did not

contact or drag against the frame.

I polished the leaves by rubbing the appropriate

surface against my 400-grit polishing stick.

Next

I cleaned up and polished the disconnector.

I polished the slanted area by rubbing it on a 600-grit

polishing stick. I

also polished the flat portion behind this.

Finally I used a Cratex® tip to polish the tip of the

extractor to make it very smooth for the disconnector rail on

the slide to ride over. I

also polished the flat back of the stem.

Now

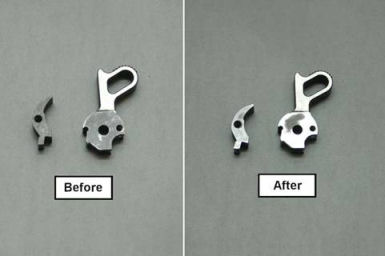

on to the sear. With

my Dremel® and a Cratex® tip I polished the two lower legs

of the sear. With

the curve facing me I polished the fronts and ends.

I

had already polished the inside of the thumb safety when I

fitted it, but I polished the sharp edge on the lower part of

the lever.

Performing

Function and Safety Checks

Now

it was time to see if all my hard work had been worth it.

I completely assembled the gun and used some dummy

rounds to perform the function and safety checks.

First I locked the slide in the rear position with the

slide stop. I

loaded ONE round into an empty magazine and inserted it into

the gun. I

released the slide stop and allowed the slide to go forward

into battery. It

fed the round into the chamber smoothly.

Then I pulled the slide back smartly and the round

ejected briskly. Good

work!

Now

with the gun empty and no magazine in it I again locked the

slide back with the slide stop.

I held the trigger fully to the rear and released the

slide and let it go into battery.

The hammer stayed back in the full cock position.

I repeated this a second time without holding the

trigger back, and again the hammer stayed at full cock.

This is the only time I will allow the slide to slam

forward without a loaded magazine.

With

the gun empty and no magazine I racked the slide to put the

hammer in the full cock position.

With my hand off of the grip safety I pulled the

trigger; it did not drop the hammer.

With

the gun empty and no magazine I racked the slide to put the

hammer in the full cock position.

Gripping the gun normally, I engaged the thumb safety

and pulled the trigger. Again,

the hammer did not drop, which is correct.

With my finger off the trigger I moved the thumb safety

to the fire position; the hammer did not drop.

I

did a little work to make the trigger pull smoother by

“pushing” the hammer.

I disassembled the gun and removed the grip safety.

I then reassembled the gun and cocked the hammer.

With my left thumb I applied additional forward

pressure to the hammer, then pulled the trigger to allow the

hammer to fall. I

did this 5 or 6 times which helped the hammer and sear mating

surfaces to work in quicker.

I

tested to see if the disconnector was resetting properly by

first pulling the hammer back into the full cock position.

I then pulled the slide back just until it pushed on

the disconnector. With

my left hand pushing on the slide I pulled the trigger, then

released the slide keeping the trigger pulled.

When I released the trigger I should have heard a click

as the disconnector reset, but the trigger would not return to

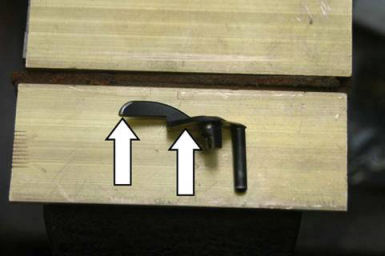

the forward position.

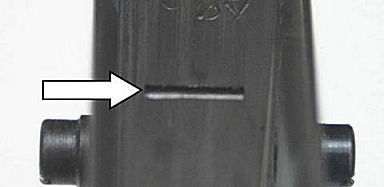

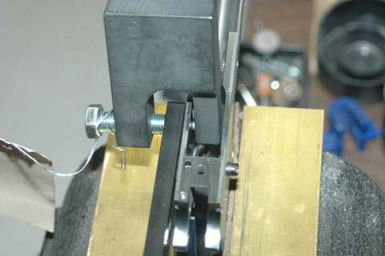

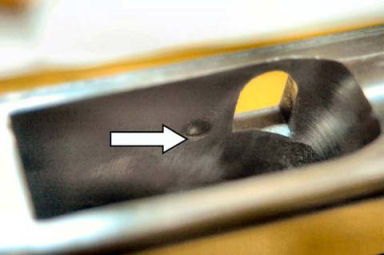

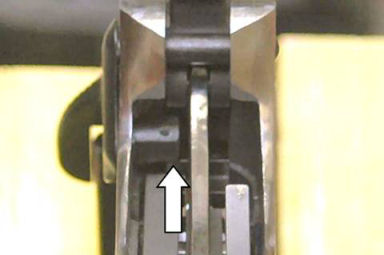

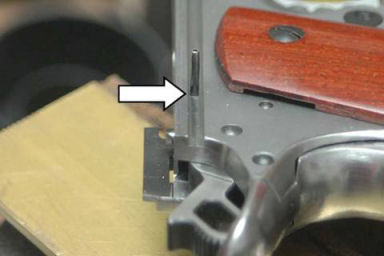

Upon

close examination I discovered that the top of the rear part

of the trigger bow was dragging on the bottom of the

disconnector. I

carefully filed the top of the rear of the trigger bow as

shown in the above photo until the trigger and disconnector

reset as they should.

Cleaning

Up and Installing Small Parts

Now

I needed to check my work and make sure I have done all of the

things that have to be done to build a Custom 1911 pistol.

I installed a .45 ACP ejector I had in my parts bin

onto the frame. Although

this ejector is not used for .22 LR cartridges, I didn’t

want there to be an empty space below the slide where the

ejector should go. Besides,

I someday may want to put a .45 upper on this frame.

First I pinned the ejector in and made sure that the

pin was flush on both sides.

It went in from right to left.

Some

of the internal parts I polished I wanted to protect the bare

metal so I cold-blued them instead.

I used a cotton swab dipped in acetone to degrease

them, then I suspended them in .

Shooter

Solutions™ Rugged Gun Blue until I got a nice deep blue.

After removing the part I wiped it dry, then stopped

the bluing process by wiping with gun oil.

I only blued the bottom half of the hammer because I

like the bare steel look, but I didn’t get the deep blue I

wanted I think because this part is hardened.

Next

I staked in the hammer strut pin to make that sure it stays

put. I used a

pointed punch to make a dent in the center of each end of the

pin to make sure that the pin wouldn’t come out.

Next

I removed the grip screw bushings and reinstalled them with

Loctite red to insure they would not come out when I removed

the grip screws. It

is very irritating to have the bushing come out with the

screw.

Bead

Blasting

Now

that I have a fully functioning 1911 it’s time to enter the

home stretch. First

I needed to prepare all the parts I planned to blue.

I purchased a used blast cabinet for about half the

price of a new one and glass bead blast media from ebay.

I wanted all visible parts to be blued so they would

first have to be bead blasted to get the same texture and

remove any original bluing.

Some

of the polished/fitted areas I didn’t want to have damaged

by the bead blasting so I protected them with masking tape.

I taped the feed ramp, top, and slide rails on the

frame.

I

took the parts to my blast cabinet and worked with the frame

first. I had my

air compressor set to 100 PSI, the maximum for the cabinet,

and held the gun fairly close to the work piece.

I made a slow back and forth pass over all external

areas until I got a nice even matt texture.

I made sure there was no bluing left on the ejector,

grip screw bushings, firing pin stop, plunger tube, and front

and rear sights. There

were a couple of areas Dremel® tool with a Cratex® bit got

away from me, but the bead blasting eliminated the marks.

Before Bead Blasting - Shiny or Blue

After Bead Blasting - Matt Texture, No Blue

Then

I concentrated on the smaller parts.

Again I made sure there was no bluing left on any of

the previously blued parts.

Bluing

Parts

Since

my .22 LR conversion kit was blued I decided to try my hand at

bluing the frame so it matched.

Professional, commercial bluing requires hot dipping

tanks and special bluing salts.

Shooter

Solutions™ has a cold bluing solution that comes out almost

looking as good as, and durable as commercial bluing.

I purchased two 4-ounce bottles of their 2.5X

Concentrated Rugged Gun Blue just to see how it would come

out.

Preparation

is everything. First

I had to clean and degrease all the parts I planned to blue.

I wore vinyl gloves so I wouldn’t contaminate the

parts with oil from my skin.

I used acetone to clean and degrease all of the parts.

I

poured one bottle of solution into a 1-cup glass measuring

cup. I used a bent

paper clip to suspend each of the small parts in the gun blue

solution for one minute. I

removed the part from the solution, dried it off, then coated

it with gun oil.

I

poured both bottles of bluing solution into a plastic pan that

came from my favorite Chinese restaurant.

I save these plastic tubs and pans and use them for

keeping small parts together, cleaning parts, etc.

After I degreased the frame I laid it in the solution.

The solution only covered half of the frame so I had to

keep flipping the frame to ensure it was evenly blued.

After about 45-seconds on each side I removed the

frame, dried it off, then coated it with gun oil.

Overall

I was very pleased with the results as you can see from the

above photo. We’ll

see just how durable this finish really is with time and use.

Lubricating

and Assembling All Parts

First

I degreased all parts by spraying with brake parts cleaner,

then dried with an air compressor.

I lightly coated all parts with BreakFree CLP then

wiped them clean.

I

reassembled the gun and put some good gun oil on the internal

moving parts. Personally

I think the result is much better than I had hoped.

Test

Firing

Now

I checked all of the functions of my 1911.

First I inserted the .22LR magazine and made sure it dropped out smoothly. I

re-checked the thumb safety for solid operation and saw that

it clicked in place firmly.

I also re-checked the grip safety function making sure

that it released the trigger when it should and that it did

not hold the trigger back when I pulled the trigger for the

next shot.

The

test fire procedure is very important.

I started with a single round in a magazine and with

the slide locked back, loaded that one round into the chamber

by depressing the slide stop and letting the slide slam home.

The round chambered with no hang-up.

I fired that one round and made sure the slide locked

back. With it

locked back, I inserted a magazine loaded with two rounds,

chambered the first round, and fired both shots.

I did not have any “doubling” where both shots were

fired with only one trigger pull.

This would have been a dangerous condition that I would

have had to fix before loading and shooting a full magazine.

Since

all seemed to be well I shot about 100 rounds to make sure

that everything was working correctly.

This also helped to “break in” the gun.

Man this gun was tight and shot better than I did!

I didn’t have any failures-to-feed (FTFs) or

failures-to-eject (FTEs) and the gun put the shots right where

I was aiming after adjusting the rear sight!

Reliability and accuracy; the results of a job well

done.

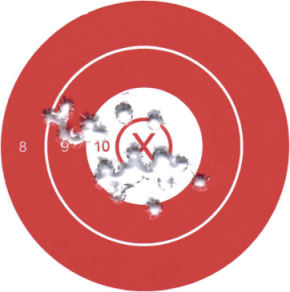

So

how does it shoot? My neighbor said it was really

smooth. The above target is 30 rounds at 8 yards so it

is not only smooth, but accurate as well. The trigger

breaks at a crisp 3 1/2 pounds which makes this gun a pleasure

to shoot.

Custom

Grips

Now that everything was working correctly I wanted to make a

set of custom grips. I have done this before (refer to

my article Making Custom Handgun

Grips) and they come out beautifully. Rather

than use wood I decide to use black Delrin® which is a

polyoxymethylene (POM), also know as acetal, polyacetal, and

polyformaldehyde. It is a synthetic polymer

thermoplastic used in precision parts requiring high

stiffness, low friction, and excellent dimensional

stability. Delrin® is DuPont's name for this polymer,

and I have found that it machines like metal and sands like

wood.

I

performed the drilling, milling, and shaping processes as

described in my article. You can see in the above photo

that the final shaping process left tool marks

behind.

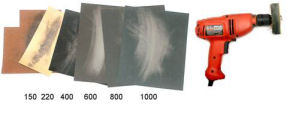

After

completing the shaping on my hobby CNC mill I sanded off the

tooling marks and polished with progressively finer grits of

sand paper starting with 150-grit and progressing to 220, 400,

600, 800, and 1,000-grit paper. I used a buffing wheel

on a drill with polishing compound to get the final high-gloss

finish I was looking for.

I

created a design that I engraved into the grips using my CNC

mill and a 0.015" bit. I tweaked the design just a

bit and put the spider web hole in the center of the O in

SHOT.

After

I completed the engraving I filled the lines with white epoxy

appliance touch-up paint. I painted the entire design so

the lines were filled with paint, then allowed the paint to

thoroughly dry. I used a cotton cleaning patch and

odorless mineral spirits to remove the excess paint from the

surface so just the filled lines were left behind.

As

you can see from the above photo the white lines really stand

out from the black polymer grips. So now I am fully

prepared for the zombie apocalypse!

|