|

|

Shooter Solutions™

Rugged Gun Blue

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Introduction

Corrosion is a firearm’s worst enemy.

Gun metal needs to be protected from corrosion.

Moisture from the air, moisture and oils from our

hands, even salt in the air if we live close to the ocean can

all contribute to the formation of Fe2O3 iron-oxide,

otherwise known as rust. Over

the decades firearms manufacturers have devised various

methods to protect the metal.

Today, the most common protection is called bluing.

Bluing

is a process in which steel is partially protected against

rust, and is named after the blue-black appearance of the

resulting protective finish.

True gun bluing is an electrochemical conversion

coating resulting from an oxidizing chemical reaction with

iron on the surface of the metal.

The resulting black oxide provides minimal protection

against corrosion, unless also treated with a water-displacing

oil to reduce wetting and galvanic action.

This explains why blued firearms must also be oiled,

and why surface rust appears on blued firearms that are not

kept oiled.

Shooter

Solutions™ Rugged Gun Blue

Modern firearms are typically hot blued; something that I, as

a home hobbyist gunsmith, am not set up to perform.

Both "cold" and "hot" bluing are

oxidizing processes, but only the "hot" process

provides any significant rust and corrosion resistance…until

now thanks to Shooter Solutions™ Rugged Gun Blue.

Shooter

Solutions™ (www.ShooterSolutions.com)

Rugged Gun Blue is a cold bluing solution that actually reacts

and converts the base metal similar to hot bluing making it

more rugged than other cold bluing products that just apply a

coating to the surface. With

Rugged Gun Blue I can now blue an entire firearm, or touch-up

small areas where factory bluing has worn off or metal has

been exposed from milling, filing, or cutting, and get

virtually the same protection as hot bluing.

The instructions that come with the product are a

little bit difficult to plow through and understand, but the

basic formula for success is fairly easy.

I

have a Marlin 1894 Cowboy rifle that I purchased used many

years ago. The

previous owner had wrapped the lever with leather, which must

have been chrome-tanned because it corroded the metal and ate

away the finish. Chrome-tanned

leather leaves tanning salts behind which will corrode metal.

Leather that will sit against metal – like holsters

– should be vegetable-tanned.

A new lever costs about $60.00 but I can restore my

existing one for much less using Rugged Gun Blue.

- Wear

vinyl or nitrile gloves – this product is an acid so

gloves should be worn at all times.

Gloves also protect the prepared metal from

becoming contaminated by the oils from your skin.

- Bead/sand

blast or sand the part if necessary – When I am building

a new gun, or restoring an older gun I bead-blast the

parts with glass bead media to get a soft, matt finish.

If I want a smooth finish I polish the metal with

progressively finer grits of silicon/carbide wet/dry sand

paper.

For a gun with factory bluing, you do not have to remove

all the old bluing; Shooter Solutions™ instructions state

that Rugged Gun Blue can blend with factory bluing.

- Degrease

– I use acetone. It

is important to remove any grease or oil from the metal so

the Rugged Gun Blue can work on the base metal itself.

It is also important to remove any metal dust from

sanding, cutting, or milling; otherwise the solution will

react with the metal dust and not the base metal making

the result less rugged.

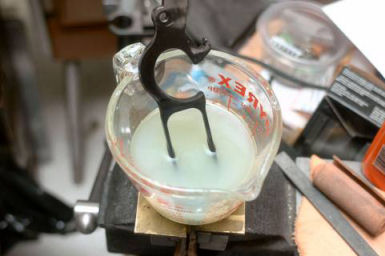

Note:

The solution is milky because I have been using it and

it has some impurities in it.

- Dip

or soak the part in the Rugged Gun Blue solution until it

is dark blue/black – properly prepared metal only

requires a few seconds, contaminated metal may take

longer. If you

leave the part in the bluing solution too long it can

start to eat away the base metal and change tolerances and

specifications. If

you can wipe off a black pigment/powder from the part,

then you have left it in too long.

You can also apply the Rugged Gun Blue using a brush so

long as you keep the part wet so the base metal has enough

time to react. Never

apply the solution with a cotton swab, rag, or paper towel

as these contain chemicals that can interfere with the gun

blue solution.

- Rinse

the part with water to remove the excess acid solution

- Dry

with a hair dryer, heat gun, or air compressor – You may

see some orange rust appear; this is normal and will

disappear when oiled.

- Apply

gun oil – I use a cotton swab soaked with gun oil to get

into all the corners, crevices, pin holes and screw holes.

Do not use Breakfree CLP or metal polish as they

will remove your newly applied gun blue finish.

The

solution can become contaminated over time, but you can filter

out many of the impurities by straining it through a coffee

filter. This is

good to know to extend the life of the solution.

Results

I

have used other cold gun blue products in the past and have

never been pleased with the results.

This is because most of them do not react with, and

convert the base metal so they are neither dark enough, nor

rugged enough. This

product absolutely amazed me by the color, depth, and evenness

of the result as you can see by the 1911 frame in the above

photo. I built a

dedicated 1911 .22LR using an Advantage Arms .22LR conversion

kit and a 1911 frame that I built up from parts.

The conversion kit already came blued, but notice how

the frame matches it perfectly.

I blued the frame, thumb safety, grip safety, and

mainspring housing using Rugged Gun Blue; I could not have

asked for better results.

Refer to my article

Building

a Dedicated 1911 .22LR Pistol.

Summary

Any time I expose bare metal I use cold bluing to protect that

exposed area. This

is especially important when polishing the internal area of a

blued firearm. Polishing

removes metal, and in so doing, also removes the protective

bluing. These

polished areas need to be re-blued to provide some protection,

and cold bluing is the least expensive means of providing that

protection. Cold

bluing also can enhance the appearance of an older firearm.

I have thrown away all my other cold bluing products in

favor of Shooter Solutions™ Rugged Gun Blue.

This is my go-to cold blue solution (pun intended) from

now on.

Rugged

Gun Blue comes in 4-ounce, 8-ounce, quart, and gallon sizes

and can only be ordered online from www.ShooterSolutions.com.

I keep a quart handy in my shop at all times, not only

for guns and gun parts, but for tools as well.

I

want to extend my thanks to Jonathan Doege, owner of Shooter

Solutions™, for taking the time to talk to me and helping me to

understand the chemistry of his Rugged Gun Blue and important

do’s and don’ts of using his product.

By the way, Shooter Solutions™ also makes a black

manganese Parkerizing solution with which I have refinished

five 1911’s and they all came out beautiful.

I highly recommend both of these excellent products.

|