Adding a Tang Peep Sight to a Lever-Action Rifle

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

I

have always preferred a peep sight to an open sight.

All of my lever-action rifles have one mounted on the

tang. For cowboy

shooting competition, I remove the aperture and use the

resulting large ring as a ghost ring.

I find I can acquire the target quicker with a peep

sight than with open sights. And,

because the eye automatically lines up the front post into

the center of the ring, literally wherever I place the front

post on the target, that is where the bullet will hit.

I

recently purchased and restored a Ted Williams model 100

.30-30

Winchester

(refer to my article Restoring

a Ted Williams (Sears) Model 100 .30-30).

This rifle is really a cheaper model ’94 made by Winchester

for Sears. I had

to do a lot of smoothing and polishing to make the action

somewhat smooth, but a friend of mine purchased a real

Winchester ’94 .30-30 which was a heck of a lot smoother

than the Ted Williams model!

Although I replaced the rear sight during the

restoration process, I really wanted to put a tang peep

sight on it.

There

are three popular models of rear peep sights available for

lever-action rifles:

- Williams

Receiver Sight – made to be mounted on the receiver

and is adjustable for both windage and elevation.

However, I would not be able to fit the rifle

into my saddle scabbard so I chose not to use this one.

- Lyman

#2 tang peep sight – made to be mounted on the

receiver tang, this sight is not adjustable for windage,

only elevation. You

have to drift the front sight the opposite

direction you want the bullet to move.

However, this sight costs almost $50 less than

the Marbles sight.

- Marbles

tang peep sight - made to be mounted on the receiver

tang, this sight is adjustable for both windage and

elevation. Although

more expensive than the Lyman, I wanted the ability to

adjust windage without having to use a mallet and punch.

Marbles has been manufacturing tang peep sights

for over 100 years.

I

ordered item 174097 Marble's

Tang Peep Sight

Winchester

53, 55, 64, 65, 1892, 1894 Steel Blue and item 735034 Marble's Improved Tang Peep Sight Screw Set #3 Blue from Midwayusa.

A few years ago I purchased the same sight for my Rossi

’92 and it came with the screws.

Apparently, Marbles decided to sell just the sight, and

sell the rifle-specific screws separately.

The

base of the tang sight comes with two holes; one will align

with the original hole in the tang that holds the butt stock

in place. I will

have to drill and tap the tang for the front hole in the sight

base. First, I

made sure my rifle was unloaded, then I removed the tang

screw. I installed

the peep sight and new, longer tang screw with a piece of

leather used as a shim. This

raised the sight above the tang, which helped me to mark the

center of the tang for the new hole.

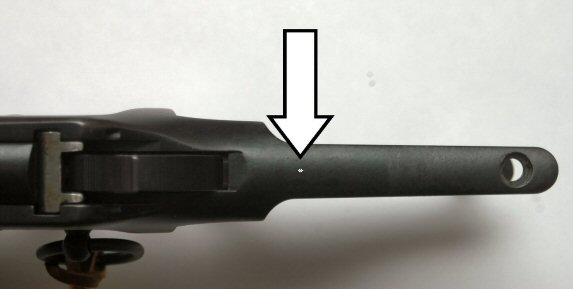

I placed a letter ‘C’ drill bit through the front

hole in the sight base and turned it with my

hand to mark where to drill.

Just to make sure I was in the center of the tang, I

measured the width of the tang at the point I made the mark,

then divided by two; the result was 0.276”.

I used the calipers to make a line on the tang, then

used a center punch to mark where the line and drill mark came

together. The

base of the tang sight comes with two holes; one will align

with the original hole in the tang that holds the butt stock

in place. I will

have to drill and tap the tang for the front hole in the sight

base. First, I

made sure my rifle was unloaded, then I removed the tang

screw. I installed

the peep sight and new, longer tang screw with a piece of

leather used as a shim. This

raised the sight above the tang, which helped me to mark the

center of the tang for the new hole.

I placed a letter ‘C’ drill bit through the front

hole in the sight base and turned it with my

hand to mark where to drill.

Just to make sure I was in the center of the tang, I

measured the width of the tang at the point I made the mark,

then divided by two; the result was 0.276”.

I used the calipers to make a line on the tang, then

used a center punch to mark where the line and drill mark came

together.

I

completely disassembled the rifle, including removing the

magazine tube. I

placed the tang in my machinist’s vise, then used a #21

drill bit to drill the hole in the tang. The

screw kit came with two screws; 10-32 and 10-36.

Since I had a 10-32 tap, this is what I used to tap the

hole. To ensure I

started the hole straight, I brought the quill of my

mill/drill down to where the shank of the tap was inside the

chuck, then tightened the chuck to where the tap would still

turn. I clamped

vise-grips on the tap and started to turn it. Once

the tap was started, I finished tapping the hole with a tap

wrench. I

completely disassembled the rifle, including removing the

magazine tube. I

placed the tang in my machinist’s vise, then used a #21

drill bit to drill the hole in the tang. The

screw kit came with two screws; 10-32 and 10-36.

Since I had a 10-32 tap, this is what I used to tap the

hole. To ensure I

started the hole straight, I brought the quill of my

mill/drill down to where the shank of the tap was inside the

chuck, then tightened the chuck to where the tap would still

turn. I clamped

vise-grips on the tap and started to turn it. Once

the tap was started, I finished tapping the hole with a tap

wrench.

I

cleaned out the hole with brake parts cleaner, then oiled and

reassembled the rifle. I

installed the new tang sight using blue thread locker on the

screws. Finally, I

tapped out the new front sight and replaced it with a dovetail

sight blank. Now

my rifle is ready to be sighted-in. I

cleaned out the hole with brake parts cleaner, then oiled and

reassembled the rifle. I

installed the new tang sight using blue thread locker on the

screws. Finally, I

tapped out the new front sight and replaced it with a dovetail

sight blank. Now

my rifle is ready to be sighted-in.

This

project is fairly easy, even if all you have is a hand drill. The

secret is to make sure you have the front hole properly

centered on the tang. Receivers

are usually made out of softer steel so they’re easy to

drill and tap. And,

even if your drill is not perfectly straight, or the tap is

not started perfectly straight, the front screw will still

hold the sight in place.

|