Building

the V-10 Hog Hammer

by Roy Seifert

Click here to purchase a

CD with this and all Kitchen Table Gunsmith Articles.

Disclaimer:

This article is for entertainment only and is not to

be used in lieu of a qualified gunsmith.

Please defer all firearms work to a qualified

gunsmith. Any loads

mentioned in this article are my loads for my guns and have

been carefully worked up using established guidelines and

special tools. The

author assumes no responsibility or liability for use of

these loads, or use or misuse of this article.

Please note that I am not a professional gunsmith,

just a shooting enthusiast and hobbyist, as well as a

tinkerer. This

article explains work that I performed to my guns without

the assistance of a qualified gunsmith.

Some procedures described in this article require

special tools and cannot/should not be performed without

them.

Warning:

Disassembling and tinkering with your firearm may

void the warranty. I

claim no responsibility for use or misuse of this article.

Again, this article is for entertainment purposes

only!

Tools

and firearms are the trademark/service mark or registered trademark

of their respective manufacturers.

Background

I am an avid gun collector and shooter, but have never been

a hunter. As I

get older I find I would like to experience “the thrill of

the hunt.” I’ve

tried my hand at turkey hunting, and when paired with a

knowledgeable and experienced hunter, I had a great time and

thoroughly enjoyed the experience.

I decided I would like to try my hand at hog (wild

pig) hunting, specifically with a handgun, so I decided to

build my idea of the ultimate hog hunting handgun, the

“V-10 Hog Hammer.”

I decided

to use a stainless steel Ruger Blackhawk in .45 LC with a 7

1/2“ barrel as the platform for my project.

The reasons for this were numerous.

A long time shooting friend purchased a Ruger Bisley

Blackhawk in .45 LC with a 7 1/2“ barrel to use for

hunting. After

reading an article about how to safely load the .45 LC up to

.44 Magnum performance and beyond I agreed with his

decision. Ruger

makes the Bisley Blackhawk only in a blued version, but I

wanted stainless steel so I had to get the regular

“plowshare” grip Blackhawk.

Caution:

The following load is above SAAMI specifications and

should be approached with caution and used only in modern

firearms. The

author of the article I read had a pet hog load of 20 grains

of Alliant 2400 under a 300 grain hard cast lead wide flat

nose bullet. I

purchased a Lee 300 grain .452 wide flat nose gas check bullet

mold and cast my own. This

load chronographed from my Marlin 1894 Cowboy at 1500 feet per

second (fps), and from the 7 1/2” Blackhawk at 1240 fps.

Pressure was measured at 32,000 PSI using a Pressure

Trace™ unit. Although

this is beyond some published maximums for this caliber, many

powder and bullet companies are publishing loads within this

range specifically for use in modern firearms.

Planned

Improvements

Ruger makes a fine single-action revolver.

But like most production firearm manufacturers they

can’t afford to take the time to make the custom

improvements to really make this revolver into an excellent

shooter. Based on

Internet research, apparently Ruger revolvers have other

problems that are counter-productive to accuracy, which I will

identify later. Beginning

with the stainless steel Ruger Blackhawk 7 1/2“ barrel in

.45 LC I planned to make the following improvements:

- Install

a Wolff spring kit. I

really like how this smoothes and lightens the action.

- Lighten

the trigger pull – at the same time eliminate some of

the creep inherent in all Ruger single-action (SA)

triggers.

- Install

a wide spur hammer ala Super Blackhawk.

I don’t want my thumb to slip off the hammer

under the stress of “buck fever” (or should I say

“hog” fever) or in cold or wet conditions.

- Checker

the hammer spur for greater purchase.

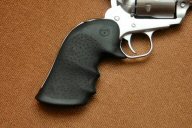

- Install

a Hogue single piece rubber grip.

These hog loads can kick quite a bit and the

plow-share grip will rotate in my hand under recoil.

I want to control the recoil better.

- Install

a scope mount for a red dot sight or 2x pistol scope.

I want to be able to interchange the optics

depending on the shooting conditions; red dot for close

range, 2x scope for long range.

- Port

the barrel – I plan to drill 5 holes along either side

of the front sight base to help reduce recoil.

- Open

up the chamber throats if necessary.

- Lap

the barrel – This will improve overall accuracy.

- Convert

existing pawl into a free-spin pawl.

This makes single reloads very easy.

I had

thought about reducing the barrel to 6” for easy carrying,

but decided I wanted the extra length especially because I’m

going to port it.

Install

Spring Kit and Wide Spur Hammer

First I installed the spring kit.

I purchased kit RSA-106 from Brownells

which contained a reduced power trigger return spring, 17, 18,

and 19 lb. hammer springs (factory is 23 lb.), and a stronger

base pin plunger spring. First

I completely disassembled the gun and polished all trigger

parts and pins. I

made sure the trigger was not rubbing against the grip frame.

(One of my Vaqueros wouldn’t work with the reduced

power trigger return spring because the trigger was rubbing

against the grip frame. I

had to relieve that edge of the trigger slot for the gun to

function with the Wolff spring.)

After

polishing, cleaning and oiling all internal parts I

reassembled the gun using the spring kit with the 17lb.

mainspring to test for reliable function.

I purchased a wide-spur hammer from Brownells and

replaced the factory hammer at the time I reassembled the gun.

The gun functioned well and all springs worked as they

should, but I encountered my first problem.

If I cocked the hammer and pulled the trigger back at

the same time something in the lock work hung up which caused

a very heavy trigger pull.

By holding the hammer back and pulling the trigger 2-3

times I could feel something flexing, then I heard a

“click” inside the action and the heavy trigger tension

was gone.

Over the

years I’ve worked on dozens of Ruger single action revolvers

and every one was just a bit different due to manufacturing

variances. This

was one of those instances where, due to the manufacturing

process, something was causing the lock work to hang up.

I

discovered that the end of the trigger return spring was

catching on the rear edge of the transfer bar arm as you can

see in the left photo. There

was a small ridge left from the casting that would catch the

end of the spring. Eventually,

the spring would rotate away from the arm causing the audible

“click”, which relieved the spring tension.

I checked my other spring kit (I always keep a couple

in the shop) and also compared it to a factory spring.

They were all the same dimension; therefore something

had to be done about the trigger. I

discovered that the end of the trigger return spring was

catching on the rear edge of the transfer bar arm as you can

see in the left photo. There

was a small ridge left from the casting that would catch the

end of the spring. Eventually,

the spring would rotate away from the arm causing the audible

“click”, which relieved the spring tension.

I checked my other spring kit (I always keep a couple

in the shop) and also compared it to a factory spring.

They were all the same dimension; therefore something

had to be done about the trigger.

My

solution was to relieve the inside edge of the transfer bar

arm so the end of the spring wouldn’t catch.

I used my milling machine and a 1/8” end mill to make

the relieving cuts, then smoothed it with the edge of a cutoff

wheel and my Dremel tool.

I could have simply used my Dremel tool to relieve that

edge, but I think it would have taken longer.

There is no weight or tension on the transfer bar, but

like most things Ruger builds, this arm was probably

over-engineered. My

relief cut should have no adverse effect on function,

durability or reliability. My

solution was to relieve the inside edge of the transfer bar

arm so the end of the spring wouldn’t catch.

I used my milling machine and a 1/8” end mill to make

the relieving cuts, then smoothed it with the edge of a cutoff

wheel and my Dremel tool.

I could have simply used my Dremel tool to relieve that

edge, but I think it would have taken longer.

There is no weight or tension on the transfer bar, but

like most things Ruger builds, this arm was probably

over-engineered. My

relief cut should have no adverse effect on function,

durability or reliability.

Lighten

the Trigger Pull

There are some tricks I use to make a Ruger SA trigger lighter

and crisper. First

and foremost is installing the spring kit as performed above.

With most Ruger SA triggers the trigger sear sits too

deeply on the hammer notch.

Also the engagement surfaces are usually just rough

ground as they come from the factory.

This makes a very safe, but long and creepy trigger

pull. Some of the

things I can do are to reduce the hammer notch to about

0.014”, cut a break-away angle on the rear of the trigger

sear, and bevel the edges of the trigger sear so less surface

area engages the hammer. These

processes require special tools and jigs in order to keep the

surfaces square.

I installed

the hammer in my Power Custom Series 2 stoning fixture using

the universal adapter. I

used the original hammer pivot pin inserted groove first into

one of the holes in the adapter.

The pin was held in place by a set screw.

I made sure the set screw contacted the groove so as

not to raise a burr on the outside of the pin.

I marked the front edge of the hammer notch with a blue

marker and adjusted the fixture until my stone was flat across

the front of the notch. The

notch in my hammer measured 0.022” so I took a 220 grit

stone and carefully reduced the depth of the notch to

0.014”.

I

then rotated the hammer so I could polish the engagement

surface of the hammer notch as shown in the left photo.

I marked the surface with a blue marker and made sure

to adjust the fixture so I was polishing this surface

perfectly flat. I

used my hard Arkansas stone with a beveled edge to

final-polish the surface. I

then rotated the hammer so I could polish the engagement

surface of the hammer notch as shown in the left photo.

I marked the surface with a blue marker and made sure

to adjust the fixture so I was polishing this surface

perfectly flat. I

used my hard Arkansas stone with a beveled edge to

final-polish the surface.

Next I installed the trigger in my Power Custom Series 1

stoning fixture using the BH (Blackhawk) adapter.

I used a blue marker to mark the surface and adjusted

the fixture until I was polishing the surface perfectly flat

and square. I used

my coarse ceramic stick to polish off all of the grinding/

machine tool marks, then final polished with my fine ceramic

stick.

Finally

I cut the break-away angle in the trigger sear.

The arrow in the left photo shows which corner I cut.

Cutting this angle causes less surface area of the sear

to ride on the hammer notch. With

the trigger still installed on the BH adapter, I rotated the

adapter until I could cut the corner at a 45o

angle. I used a

220 grit narrow stone to cut the corner.

I used about 30 strokes, then cleaned and oiled the

surface. I had to

be very careful here. If

I cut the angle too deep the sear would slip off of the

trigger. The goal

was to make the trigger pull crisp, but still be safe. Finally

I cut the break-away angle in the trigger sear.

The arrow in the left photo shows which corner I cut.

Cutting this angle causes less surface area of the sear

to ride on the hammer notch. With

the trigger still installed on the BH adapter, I rotated the

adapter until I could cut the corner at a 45o

angle. I used a

220 grit narrow stone to cut the corner.

I used about 30 strokes, then cleaned and oiled the

surface. I had to

be very careful here. If

I cut the angle too deep the sear would slip off of the

trigger. The goal

was to make the trigger pull crisp, but still be safe.

I

re-assembled the gun and tested the trigger.

With the 17 lb. hammer spring installed, it broke at

exactly 2.5 pounds every time with no creep.

To test for safety, with the hammer cocked I pushed on

the rear of the hammer with my thumb as hard as I could.

If the hammer didn’t slip off of the sear then I knew

it was safe. I

re-assembled the gun and tested the trigger.

With the 17 lb. hammer spring installed, it broke at

exactly 2.5 pounds every time with no creep.

To test for safety, with the hammer cocked I pushed on

the rear of the hammer with my thumb as hard as I could.

If the hammer didn’t slip off of the sear then I knew

it was safe.

I decided

to re-install the factory 23 lb. mainspring to get a little

quicker lock time. This

brought the trigger pull up to a very crisp 2.75 lbs.

This should help me stay on target during that all

important shot with the target in my sights.

Checkering

the Hammer Spur

The wide spur hammer I purchased came with horizontal grooves

cut in the spur. I

wanted to increase the grip by cutting vertical grooves

thereby checkering the spur.

First I

took a flat jeweler’s file and using the top groove as a

guide, cut a deep notch in front of the spur.

This provided clearance for my checkering file.

I took my 20 lines-per-inch (LPI) checkering file and

cut the vertical lines. I

believe the hammer was surface hardened because making the

initial cuts was somewhat difficult.

Once I broke through the surface, however, the cutting

proceeded smoothly. First

I cut all the vertical lines as deeply as I could with the

checkering file. Then

I went back and cleaned up each individual line with a

3-square file.

After

cleaning up all the individual lines I took a half-round

jeweler’s file and cleaned up the excess cuts on the top of

the hammer, then shoe-shined this area with strips of 320 grit

wet/dry paper. After

re-assembling the gun I definitely got better gripping

purchase on the spur. The

checkering digs more sharply into my thumb for more positive

cocking. This will

be important in the field, especially in wet conditions or if

I’m wearing gloves because of the cold. After

cleaning up all the individual lines I took a half-round

jeweler’s file and cleaned up the excess cuts on the top of

the hammer, then shoe-shined this area with strips of 320 grit

wet/dry paper. After

re-assembling the gun I definitely got better gripping

purchase on the spur. The

checkering digs more sharply into my thumb for more positive

cocking. This will

be important in the field, especially in wet conditions or if

I’m wearing gloves because of the cold.

Hand-checkering

is a very time-consuming process.

Just to cut the vertical lines on probably 6/10 square

inch of hammer spur took me over 2 hours.

But the result was well worth the effort.

Installing

Hogue Mono-Grip

I purchased a Hogue slip-on one piece rubber grip for the

Blackhawk. I love

these grips and have them installed on all my double-action

revolvers. They do

an excellent job of helping to control recoil and they should

do the same on the Hog Hammer.

The grip is

designed to fit both the Blackhawk and Super Single Six and

comes with two cross pins for different sizes of grip frames.

I couldn’t get the nut to fit on my grip frame so I

took a narrow Swiss pillar file and filed the bottom notch

deeper in the grip frame.

Once I got the nut in place and installed the narrow

cross pin, I slid the grip into place.

It didn’t fit perfectly so I took a knife and removed

a bit of rubber from the inside bottom of the grip.

Now it fit perfectly and screwed down tightly in place. The grip is

designed to fit both the Blackhawk and Super Single Six and

comes with two cross pins for different sizes of grip frames.

I couldn’t get the nut to fit on my grip frame so I

took a narrow Swiss pillar file and filed the bottom notch

deeper in the grip frame.

Once I got the nut in place and installed the narrow

cross pin, I slid the grip into place.

It didn’t fit perfectly so I took a knife and removed

a bit of rubber from the inside bottom of the grip.

Now it fit perfectly and screwed down tightly in place.

Wow, this

is a large grip! It’s

almost too big for my hand and may take some getting used to.

However, the size should help in controlling recoil,

which was the original plan.

I’ll have to do some test firing to see how it feels

in my hand, especially with gloves on.

In theory, by the time I port the barrel and add the

weight of a scope mount and optics, recoil should be pretty

tame.

Porting

the Barrel

Ok, now for some serious metal work.

I planned to mill five 1/8” holes along each edge of

the front sight base in a ‘V’ pattern, hence the name

V-10. The outside

diameter of the barrel is 0.7” and the width of the front

sight base is 0.37”. That

puts each edge about 30° off vertical center.

Rather than drill each hole pointing towards the center

of the bore, I planed to drill them aligned as closely to

vertical as possible, which should help control recoil more

effectively.

Based on

other articles I’ve read on the Internet, starting 0.325”

from the end of the barrel, each 1/8” hole will be 0.1875”

apart. I set the

barrel on a 1” parallel in my machinist vise and rotated it

until the front sight base was resting against the edge of the

vise. Then I

positioned the bit 0.010” away from the sight base itself.

With my dial indicator properly set up to measure

distance between holes I was ready to begin milling.

The article

suggested using a round end carbide bit to avoid leaving a

burr on the inside of the barrel; bad idea!

Not only did I break two bits, but I left a burr inside

the barrel on each hole. In

the left photo you can see the end of a broken bit at 3

o’clock inside the barrel.

What I should have done was use a flat end mill bit,

and driven a copper- jacketed bullet into the bore to drill

into to prevent burrs. I

used plenty of cutting oil to keep the bit and barrel cool,

and plunged the bit very slowly.

Still I was plunging too quickly when the bit broke

through on two holes and as a result I broke two bits. The article

suggested using a round end carbide bit to avoid leaving a

burr on the inside of the barrel; bad idea!

Not only did I break two bits, but I left a burr inside

the barrel on each hole. In

the left photo you can see the end of a broken bit at 3

o’clock inside the barrel.

What I should have done was use a flat end mill bit,

and driven a copper- jacketed bullet into the bore to drill

into to prevent burrs. I

used plenty of cutting oil to keep the bit and barrel cool,

and plunged the bit very slowly.

Still I was plunging too quickly when the bit broke

through on two holes and as a result I broke two bits.

Ok, after

cleaning up all the holes I had a number of burrs to remove.

First I chucked the frame and barrel in my vise muzzle

up resting on a piece of leather, and started driving bullets

down the bore. I

started with pure lead round ball, then went to hard cast

lead, then finally drove copper jacketed bullets down the

bore. During this

process I discovered another problem with this gun; there was

a constriction in the barrel where the threads were screwed

into the frame. Apparently

this is quite common for revolver barrels, especially Rugers

of .44 and .45 calibers, and can’t be good for accuracy.

There are

some methods to correct this; either fire-lap, hand-lap, or

swag the barrel. I

decided to try swaging by first impregnating copper-jacketed

bullets with 400 girt lapping compound, then driving them

through the bore. After

about 50 bullets or so all of the burrs were removed from the

right port holes, but the left holes still showed some

scraping of the bullets indicating a burr.

This was the side where I broke the two bits, which

left larger burrs.

Hand-Lapping

the Barrel

Hand-lapping involved making a pure lead lap, impregnating it

with lapping compound, and running it down the bore by hand.

First, however, I needed to remove the barrel from the

frame.

I always

feel as if I’m encroaching into a forbidden area when I

separate a barrel from a frame; almost as if I’m not

allowed! There’s

only one right way to remove the barrel from the frame and

that’s with a barrel vise and action wrench; both of which

are available from Brownells.

Before I completely disassembled the gun I used a prick

punch to mark the position of the barrel in relation to the

frame. I placed

the witness marks on the bottom of the barrel between the

ejector shroud and cylinder pin holes so they wouldn’t show

when the gun was reassembled.

These marks ensured I had the barrel properly indexed

to the frame for reassembly.

I attached

the action wrench to the frame using the Blackhawk receiver

blocks, and attached the barrel vise to the barrel using an

aluminum bushing I had to make with my hobby CNC mill.

I clamped the barrel vise vertically in my bench vise

and the barrel came off with very little effort.

Like my father used to say, “The job is always easier

when you have the right tools!”

(Ok, I can calm down now; no damage and I didn’t mar

the barrel!)

Now that I

had the barrel separated from the receiver I was ready to

begin hand-lapping. First

I had to make the lap. I

filled my electric lead pot with pure lead and prepared my

dipper. I took a

.243 caliber brass cleaning brush and screwed it onto the end

section of a multi-section rifle cleaning rod (no handle so I

could push it out of the barrel after pouring the lead).

Then I wrapped the end of the rod where the brush

screwed in with masking tape so it would fit tightly into the

barrel. I inserted

this into the barrel from the muzzle end until the end of the

brush was about 1/4“ below the forcing cone.

(I couldn’t pour from the muzzle end because lead

would fill the ports and I’d never be able to remove the

lap!) Then I

wrapped the barrel threads with masking tape, which protected

them from both lead and lapping compound.

I wrapped a piece of suede around the barrel and held

it at an angle with a pair of pliers, then used my lead dipper

to pour lead down the barrel over the cleaning brush.

I stopped pouring just before the lead got to the

forcing cone. I

put the barrel in my vise and tapped out the lap. Now that I

had the barrel separated from the receiver I was ready to

begin hand-lapping. First

I had to make the lap. I

filled my electric lead pot with pure lead and prepared my

dipper. I took a

.243 caliber brass cleaning brush and screwed it onto the end

section of a multi-section rifle cleaning rod (no handle so I

could push it out of the barrel after pouring the lead).

Then I wrapped the end of the rod where the brush

screwed in with masking tape so it would fit tightly into the

barrel. I inserted

this into the barrel from the muzzle end until the end of the

brush was about 1/4“ below the forcing cone.

(I couldn’t pour from the muzzle end because lead

would fill the ports and I’d never be able to remove the

lap!) Then I

wrapped the barrel threads with masking tape, which protected

them from both lead and lapping compound.

I wrapped a piece of suede around the barrel and held

it at an angle with a pair of pliers, then used my lead dipper

to pour lead down the barrel over the cleaning brush.

I stopped pouring just before the lead got to the

forcing cone. I

put the barrel in my vise and tapped out the lap.

I started

with 220 grit lapping compound and found this was so coarse

that I had to drive the lap through the barrel with a mallet.

Because of this I drove the lap always from the forcing

cone to the muzzle (same direction as bullet travel) and tried

to line up the rifling the same way every time.

Once I mis-aligned the rifling so I had to remake my

lap. I thoroughly

cleaned and oiled the barrel before doing another pour.

After every 20 passes I cleaned and slugged the barrel.

It took about 40 passes to remove the constriction in

the barrel. I started

with 220 grit lapping compound and found this was so coarse

that I had to drive the lap through the barrel with a mallet.

Because of this I drove the lap always from the forcing

cone to the muzzle (same direction as bullet travel) and tried

to line up the rifling the same way every time.

Once I mis-aligned the rifling so I had to remake my

lap. I thoroughly

cleaned and oiled the barrel before doing another pour.

After every 20 passes I cleaned and slugged the barrel.

It took about 40 passes to remove the constriction in

the barrel.

I cleaned

the barrel and made a new lap and impregnated it with 400 grit

compound. This was

fine enough that I could move the lap back and forth by hand.

I made sure I pushed and pulled the lap so most of it

was exposed before reversing direction.

Note in Figure 16 above that the barrel is mounted in

the vise using the aluminum barrel bushing I used to remove

the barrel. Some

experts say that if you squeeze the barrel linearly in a vise

you can cause the barrel to be somewhat egg shaped after

lapping. I tried

final polishing with 800 grit but it was too fine and the lap

was too small to really do much good. After

completing the hand lapping process I again slugged the

barrel. This time the barrel was smooth with no

constriction and all burrs were removed.

Lapping

Barrel Shoulder to Frame

Before reassembling the gun I wanted to lap the barrel

shoulder to the frame. Most

production rifles and revolvers where the barrel is screwed

into the frame are usually way too tight.

This can cause two problems; a constriction in the

barrel at the threads (which I had!), and if the barrel

shoulder and frame are not perfectly square undue stress is

applied to both the barrel and frame which ultimately affects

accuracy. (Since

every firearm is different this may not apply to every one.)

The solution to both problems is to lap the barrel

shoulder to the frame.

In the left

photo above, I have begun the lapping process.

I was careful not to get any lapping compound on the

threads. This

would cause a loose fit. With

the barrel shoulder just touching the frame, the distance

between the witness marks was about 1/4“.

This indicated just how tightly the barrel was screwed

into the frame.

With 400

grit lapping compound applied only to the frame I continually

tightened and loosened the barrel by hand.

I occasionally recharged the compound again being

careful not to get any on the barrel threads.

I stopped when the two witness marks were a little over

1/8” apart and cleaned off the lapping compound.

The grey area in the above center photo indicates that I’ve lapped

the shoulder completely around the frame.

The above right photo shows the location of the witness marks

after lapping.

Re-Attaching

the Barrel

Now that the shoulder is lapped to the frame I’m ready to

reassemble the gun. Since

the barrel won’t be as tight as before I used Loctite to

make sure the barrel stayed in place.

I cleaned the threads on both the barrel and frame,

barrel shoulder and front of the frame with acetone and a

cotton swab. I

applied Loctite 222 to the threads, and Loctite 609 to the

shoulder. Loctite

222 (purple) is a low strength thread locker, and Loctite 609

(green) is specifically made for use where metal contacts

metal such as for pressed fittings.

This is just right for use where the barrel shoulder

contacts the frame. I

let this set for 24 hours before doing any additional work.

After

waiting 24 hours I slugged the barrel again and was pleased to

find the barrel constriction was gone, the burrs were gone,

and the barrel was nice and smooth.

The slug measured exactly 0.451”, which told me I

needed to size my cast loads to 0.452” for maximum accuracy.

I reassembled the gun using blue Loctite on all screws.

Barrel/Cylinder

Gap

One of the other

advantages to lapping the shoulder of the barrel was to reduce

the barrel/cylinder gap. Since

I removed metal from both the barrel shoulder and frame, the

end of the barrel was now closer to the end of the cylinder.

After reassembling the gun my barrel/cylinder gap was

less than 0.0015” which is way too small to be safe.

I used a 0.625” facing cutter with .45 pilot bushing

and guide to cut the face of the barrel forcing cone to

0.003”. Three

thousandths should be more than enough for safety, but provide

a nice tight gun.

I just

lightly started to cut and it opened the gap to 0.003”.

I discovered the end of the barrel was not square

because I only cut half of the surface, the other half was not

touched. I would

have preferred 0.002” but this will be ok.

Reaming

Cylinder Throats

Undersized cylinder throats are another common problem with Ruger single action

revolvers. The key

here was to ensure the cylinder throats were close to the same

diameter as the bullets.

Since my barrel slugs to 0.451” I need to size my

bullets to 0.452”, which meant my cylinder throats should

also be 0.452” – 0.4525”.

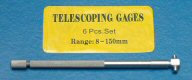

I measured

the cylinder throats using my smallest telescoping gauge and

they were 0.451” – 0.4515”.

I had used 0.452” bullets to fire-lap, and from the

cylinder throat measurements it looked like I did a good job

of lapping just the cylinder throats; they were consistent,

but undersized for 0.452” bullets.

As a comparison I measured the throats of two Ruger

Vaqueros I have and my friend’s Bisley Blackhawk, all in .45

LC. They measured

from 0.450” - 0.451”, all somewhat undersized.

I cut a

slit in a piece of 3/8” dowel and wrapped a strip of 320

grit wet/dry paper around it so it would fit snuggly in the

chamber throat. I

attached the other end of the dowel to my drill, inserted the

reamer through the chamber and ran the drill at a medium speed

while moving the reamer in and out.

I reamed each throat until it measured 0.4525”.

This not only opened up the throats, but polished them

mirror-smooth, which made them much easier to clean.

For each chamber throat I first reamed as described

above, reversed the paper to use the other end and reamed

again. This was

all it took to open up each throat. I cut a

slit in a piece of 3/8” dowel and wrapped a strip of 320

grit wet/dry paper around it so it would fit snuggly in the

chamber throat. I

attached the other end of the dowel to my drill, inserted the

reamer through the chamber and ran the drill at a medium speed

while moving the reamer in and out.

I reamed each throat until it measured 0.4525”.

This not only opened up the throats, but polished them

mirror-smooth, which made them much easier to clean.

For each chamber throat I first reamed as described

above, reversed the paper to use the other end and reamed

again. This was

all it took to open up each throat.

Revolver

Accuracy

This information is from my article Accurizing

the Ruger Single-Action Revolver but it bears

repeating here. I’m going to pause a bit and

ruminate on what I’ve learned about revolver accuracy.

With my Blackhawk in its original factory condition

this is what would be happening:

- Burning

gunpowder forces 0.452”bullet out of case into cylinder

throat.

- Cylinder

throat swags bullet to 0.450”.

- Bullet

jumps cylinder gap into barrel forcing cone.

Actually, you have to stop to think about this for

a minute. In

reality, the base of the bullet is still in the case while

the nose is engaging the rifling.

- Barrel

constriction swags bullet another 0.002” so it is now

0.448”. (The

barrel constriction in some Rugers can be as much as

0.004”!)

- 0.448”

bullet is 0.003” undersize for the 0.451” bore, bullet

wobbles as it travels down the bore, gas leaks around the

bullet causing leading, who knows how it will exit the

muzzle, resulting in a very disappointing group.

This is

what should happen with a properly sized, fitted and lapped

revolver:

- Burning

gunpowder forces 0.452”bullet out of case into cylinder

throat.

- 0.4525”

cylinder throat guides bullet into the forcing cone, no

swaging occurs.

- Bullet

jumps cylinder gap into barrel forcing cone.

- No

barrel constriction exists so 0.452” bullet enters

0.451” barrel. Because

the bullet is 0.001” oversize all lands and grooves are

sealed.

- 0.451”

bullet is in constant contact with the bore because

fire-lapping slightly tapered the bore.

Bore is sealed, no gas cutting/leading occurs.

- Bullet

exit from muzzle is consistent resulting in excellent

groups.

Mounting

Scope and Red Dot Sight

I purchased a silver Weaver mount made especially for the

Ruger Blackhawk, but the slots were spaced too far apart to

mount the red dot sight. This

looked like another job for the milling machine.

I wanted the sight to be as far back as possible so I

used the rear slot as a guide and marked where I planned to

mill a new front slot. The

original slots were 0.152” wide, so I first made a cut with

a 1/8” (0.125”) end mill, then moved it 0.027” to finish

the slot.

I chucked

the base in my machinist vise, adjusted the horizontal,

vertical, and depth of the end mill bit and made my first cut

at the mark. Using

my dial indicator I moved the bit forward 0.027” and made

the second cut without changing the depth.

Now I can successfully mount the red dot sight.

After

mounting the red-dot sight I then mounted the 2x pistol scope.

This was a simple matter of mounting the ring bottoms

to the scope mount, then mounting the scope and installing the

top rings. I put a

thin layer of clear silicon RTV inside both ring halves and

used blue Locktite on the ring screw threads.

Now this installation will not move under recoil.

Converting

Existing Pawl to a Free-Spin Pawl

The pawl is the arm that extends from inside the frame of the

revolver to engage the ratchet teeth on the rear of the

cylinder as you cock the hammer to index the cylinder to the

next chamber. With

the loading gate open the top of the pawl is in constant

contact with those teeth allowing the cylinder to rotate in

only one direction. A

free-spin pawl does not engage the cylinder with the loading

gate open thereby allowing the cylinder to rotate freely in

any direction during loading.

When the loading gate is closed the free-spin pawl

works as normal to engage the cylinder when the hammer is

pulled back. Over

the years I’ve tried using the after-market free-spin pawls

but they seem to alter the trigger pull.

This was caused by the press-fit pin backing out

causing the pawl to drag against the frame. Refer to my

article Making

a Free Spin Pawl for a Ruger Single-Action Revolver

for details on this process.

Ballistics

and Sighting In Ballistics

and Sighting In

I am using Lee bullet mold C452-300-RF which is a 300

grain .452 wide flat point bullet that takes a gas check.

I hard cast this bullet using a linotype mixture.

At the time I size and lubricate it I install the gas

check. Although

this is a very hard lead alloy, I still use the gas check

because of the velocity at which I am pushing this bullet.

This bullet comes with two crimping grooves.

The chambers in the Ruger are long enough that I can

crimp on the bottom groove, thereby reducing the amount of

distance the bullet has to jump from cylinder to barrel.

(These long rounds would not fit in my friend’s

Bisley Blackhawk because his 0.451” chamber throats were too

narrow.) By the

way, I’ve used these rounds as a gauge to determine if the

chamber throats have been reamed enough.

I measured

the ballistic coefficient (BC) for this bullet at .24 for my

particular atmospheric conditions.

(I did this by measuring the muzzle velocity and the

downrange velocity.) Lee

publishes the ballistic coefficient at .233 which is very

close to my calculations.

Using my ballistic program and knowing the velocity and

BC, I calculated point blank range.

Point blank range is defined as the maximum distance

the bullet can travel and stay within a specific diameter

circle. I wanted

to stay within a 4” circle (+2.0” above the line of sight,

and -2.0” below the line of sight.)

Based on this data the point blank range is

110 yards, sighted in at 95 yards.

(I’ll probably limit my shooting to 60 yards or

less.)

To get the

rounds sighted in I went to my local indoor range, which is

limited to 25 yards. Using

the same calculations above to be sighted in for 95 yards the

bullet should strike 0.75” high at 25 yards.

So this is where I will adjust both the scope and red

dot sight.

With this

accurized gun I regularly shoot 1/2" groups at 25 yards.

This made all my work worthwhile, and it certainly paid

off in improved accuracy.

Lessons

Learned

This project has taught me quite a bit about revolver

accuracy. I also

discovered there are proper steps to accurizing the revolver

depending on my goals. If

I didn’t want to adjust the barrel to cylinder gap I would

have slugged the barrel to determine the correct cast bullet

size, opened up the cylinder throats to accommodate that

bullet size, and removed the constriction by fire-lapping.

Since I wanted to squeeze out as much accuracy as I

could and I wanted to adjust the barrel to cylinder gap, I

removed the barrel, hand-lapped it, lapped the shoulder and

frame, reassembled, then adjusted the gap.

Then I adjusted the cylinder throats based on slugging

the barrel.

As

mentioned before, my friend’s Bisley Blackhawk has cylinder

throats that measure 0.451”, his barrel has a 0.001”

constriction, his barrel/cylinder gap is 0.007”, and the

trigger pull is 2 pounds, but long and creepy.

At a minimum I would do an action job, open the chamber

throats to 0.4525”, and fire-lap the barrel.

If he wanted the barrel/cylinder gap closed up, I would

remove the barrel, hand-lap it, then lap the barrel shoulder

to the frame.

Tool

and Parts List

Following are the tools and parts I used for this project.

|